Leon Mk1

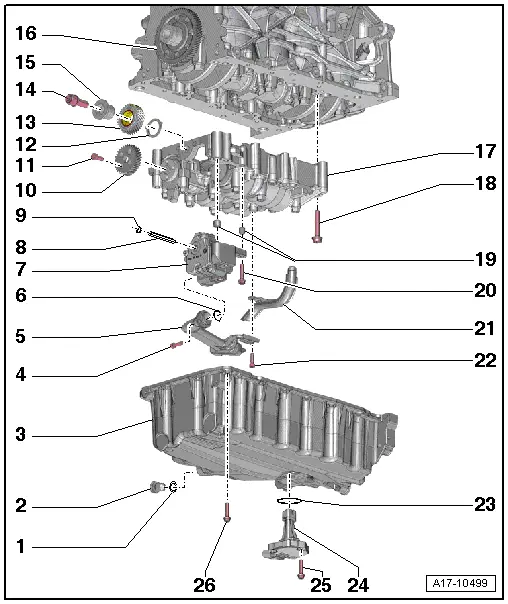

| Oil sump, oil pump, balance shaft assembly: component overview |

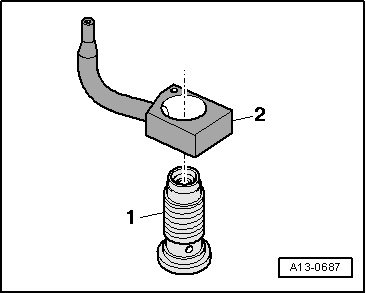

| 1 - | Seal |

| q | Replace |

| 2 - | Oil drain plug |

| q | 30 Nm |

| 3 - | Oil sump |

| q | removing and fitting → Chapter |

| 4 - | Bolt |

| q | 9 Nm |

| 5 - | Intake conduit |

| q | Clean strainer if soiled. |

| 6 - | O ring |

| q | Replace |

| 7 - | Oil pump: |

| q | removing and fitting → Chapter |

| q | Before installing, check that the two dowel sleeves for centring oil pump are fitted onto balance shaft assembly |

| 8 - | Oil pump drive shaft |

| 9 - | Circlip |

| q | Must fit securely in groove |

| q | A damaged or excessively widened securing ring must be replaced. |

| 10 - | Spur gear for balance shaft |

| 11 - | Bolt |

| q | Replace |

| q | 20 Nm ± +90° |

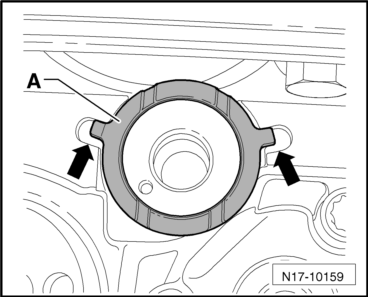

| 12 - | Thrust washer |

| q | For idler gear |

| q | Replace |

| q | Installation position → Fig. |

| q | When installing the idler gear,it must be secured with grease on the balancing module |

| 13 - | Idler gear |

| q | Replace |

| q | To achieve the correct backlash a suitably thick coating is already applied to the new idler gear; the required clearance is achieved as the coating is worn down |

| q | On idler gears with coating applied to the teeth on parts of the circumference only, a white dot indicates the correct installation position |

| q | If there is no white dot, the complete circumference of the idler gear is coated |

| q | Fitting position: Part No. must be visible |

| q | Make sure thrust washer is properly seated → Fig. |

| 14 - | Bolt |

| q | Replace |

| q | 90 Nm ± +90° |

| 15 - | Hub |

| q | For idler gear |

| q | Replace |

| 16 - | Crankshaft gear |

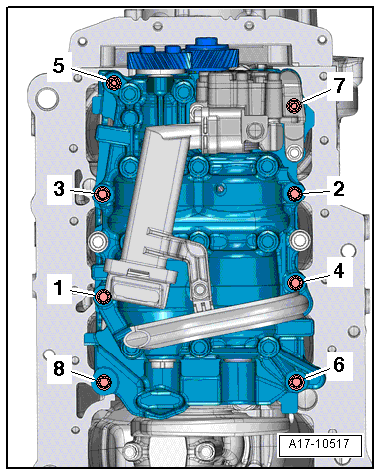

| 17 - | Balancer shaft module |

| q | Removing → Chapter |

| q | Re-installing "old" balance shaft assembly → Chapter |

| q | Installing new balance shaft assembly → Chapter |

| q | Before installing, check that the two dowel sleeves for centring balance shaft assembly are fitted on cylinder block |

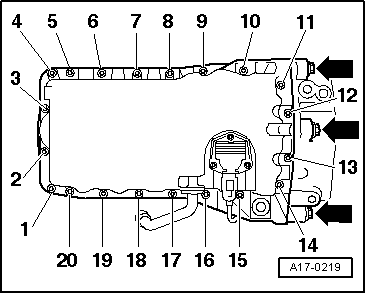

| 18 - | Bolt |

| q | Replace |

| q | Tightening torque and sequence → Fig. |

| 19 - | Guide sleeve |

| 20 - | Bolt |

| q | 9 Nm |

| 21 - | Oil suction line |

| 22 - | Bolt |

| q | 10 Nm |

| 23 - | Ring seal |

| q | Replace |

| 24 - | Oil level and oil temperature sender -G266- |

| q | removing and fitting → Chapter |

| 25 - | Bolt |

| q | Self-locking |

| q | Replace |

| q | 9 Nm |

| 26 - | Bolt |

| q | Tightening torque and sequence → Fig. |

|

|

|

|

|

|

|

|

Caution

Caution