Leon Mk1

|

| 1 - | Upper protection element for the notched belt |

| 2 - | Notched belt |

| q | Mark direction of rotation before removing |

| q | check wear |

| q | Do not bend the belt |

| q | removing, installing and tensioning → Chapter |

| 3 - | 10 Nm |

| q | replace |

| 4 - | 25 Nm |

| q | 3x |

| 5 - | 100 Nm |

| 6 - | Cogwheel for timing belt |

| 7 - | Hub |

| q | With generator wheel |

| q | Use retention tool -T10051- to loosen and tighten |

| q | For removal use the extraction tool -T10052A- |

| q | removing and fitting → Chapter |

| 8 - | Rear notched belt guard |

| 9 - | Filler cap |

| q | If this is damaged, replace it |

| 10 - | Hall sender -G40- |

| q | For the position of the crankshaft |

| q | For removing, remove the cap position → Item from the rear part of the notched belt protection |

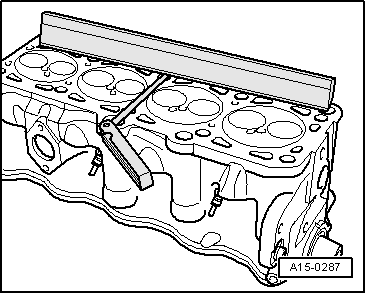

| 11 - | Cylinder head bolt |

| q | Respect the loosening and tightening sequence → Chapter |

| q | Before fitting, fit the washers to the cylinder head → Item |

| 12 - | Cylinder head cover: |

| q | Before fitting, clean thoroughly the seal surface of the cylinder head using a clean cloth |

| 13 - | Pressure limiting valve |

| q | For engine block ventilation |

| 14 - | To turbocharger |

| 15 - | Filler cap |

| q | Replace gasket if it shows signs of damage. |

| 16 - | Seal collaret |

| q | If this is damaged, replace it |

| 17 - | 10 Nm |

| q | 13 pieces |

| q | Follow the correct tightening order → Chapter |

| 18 - | Cylinder head cover gasket |

| q | If this is damaged, replace it |

| 19 - | 20 Nm |

| 20 - | Attachment rings |

| 21 - | Injector-pump: |

| q | removing and fitting → Chapter |

| 22 - | 10 Nm |

| 23 - | Central connection |

| q | for the injector pump |

| 24 - | of the brake servo |

| 25 - | Tandem pump: |

| q | For fuel feed and low pressure |

| q | check → Chapter |

| q | removing and fitting → Chapter |

| 26 - | Intake hose |

| q | From the fuel filter |

| q | White or white mark |

| q | Check for secure seating. |

| q | Immobilise with spring clips |

| 27 - | Return hose |

| q | To the fuel filter |

| q | Blue or with blue marking |

| q | Check for secure seating. |

| q | Immobilise with spring clips |

| 28 - | Seal |

| q | replace |

| 29 - | 20 Nm |

| 30 - | Cylinder head |

| q | removing and fitting → Chapter |

| q | Renew coolant after replacing cylinder head gasket |

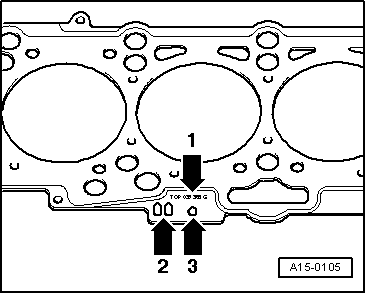

| 31 - | Cylinder head gasket |

| q | replace |

| q | Note the identification |

| q | Renew coolant after replacing cylinder head gasket |

| 32 - | Glow plug, -15 Nm |

| q | check → Chapter |

| 33 - | Tensioning roller |

| 34 - | 20 Nm + 1/8 turn (45°) further |

| q | To avoid significant damage to the engine apply correct tightening torques |

Note

Note

|

|