| –

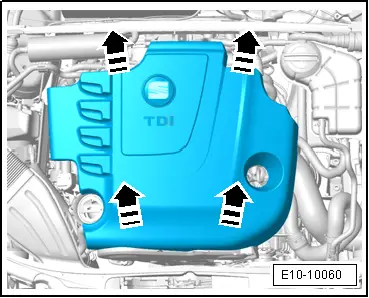

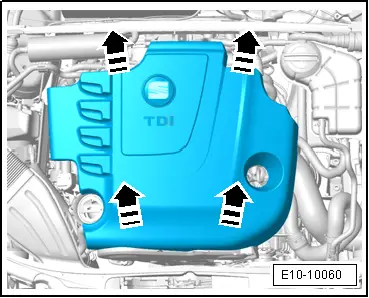

| Disconnect the engine cover-arrow-. |

| –

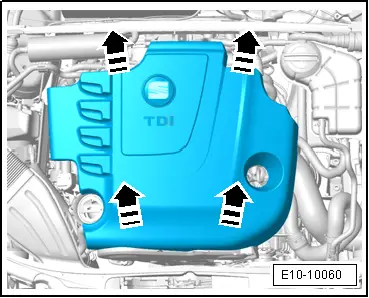

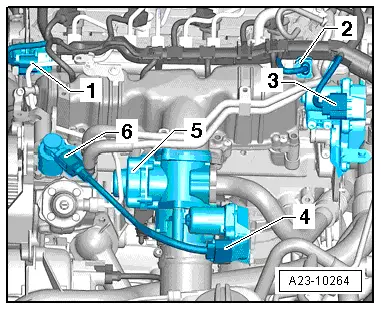

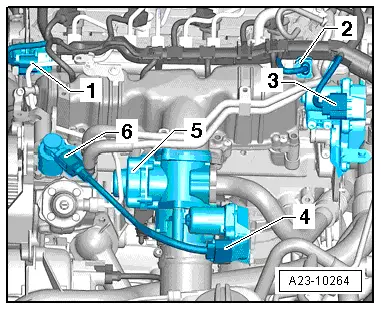

| Before disassembling clean the area of the thread around the regulation valve for fuel pressure -G247- (for e.g. with a commercial cleaning agent). No dirt should enter in the opening of the high-pressure reservoir (common rail). |

Note | Proceed carefully. The cleaning agent should not enter in the connection. |

| –

| Dry the fuel pressure sender -G247- |

| –

| Pull electrical connector from fuel pressure sender -G247-. |

| –

| Unscrew fuel pressure sender -G247-. |

| –

| Suction out the dirt from the opening of the high pressure tank (thread and sealing surface). Do not use metal tools, etc. |

Note | Seal off the opening of the high-pressure reservoir in opening immediately using a suitable plug to prevent dirt from entering. |

Note | t

| The fuel pressure sender -G247- has no sealing ring, but a deformable metal sealing. |

| t

| Note damage of the sealing surfaces (bite-edge sealing) and thread of the newfuel pressure sender -G247-. If the fuel pressure sender -G247- was inspected and is in order, another reuse is possible. |

| t

| Also check the sealing surface on the borehole of the high-pressure reservoir. |

| t

| The thread of the fuel pressure sender -G247- has a smooth paint layer, therefore no oil or grease should be present. |

| –

| Tighten the fuel pressure sender -G247- by hand. |

| –

| Subsequently tighten the fuel pressure sender -G247- on the prescribed tightening torque. |

| –

| Let the engine run for a few minutes at average speed after the assembly and then switch it off again. |

Note | The fuel system is self-bleeding; do not open the high-pressure connections. |

| –

| Consult the event memory and erase if necessary. |

| –

| Carefully check the entire fuel system for leaks. |

| Renew the affected component if leakage still occurs after tightening to the correct torque. |

| –

| Then carry out a test drive with at least one full-power acceleration. Then check high-pressure part of fuel system again for leakage. |

Note | If there is any air left in the fuel system, the engine may switch to the backup mode ('emergency running' mode) during the road test. Turn off the engine and erase event memory. Then continue road test. |

| –

| Read fault memory again after road test. |

|

|

|

Note

Note Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note Note

Note