Leon Mk1

|

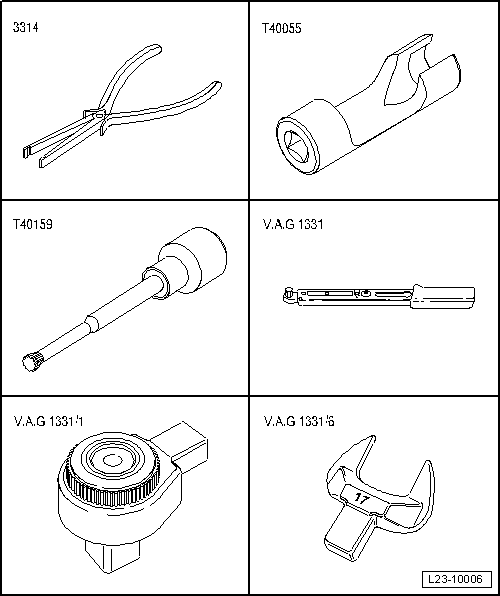

| Special tools and workshop equipment required |

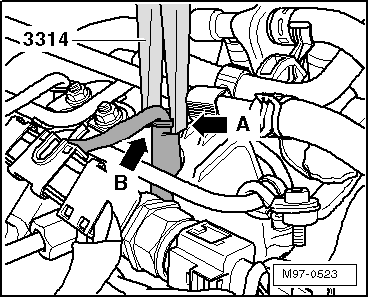

| t | Base -3314-, see equivalent → Anchor |

| t | Socket wrench insert -T40055-, see equivalent → Anchor |

| t | Socket XZN 8 -T40159-, see equivalent → Anchor |

| t | Torque wrench (5... 50 Nm) -V.A.G 1331-, see equivalent → Anchor |

| t | Ratchet 1/2' x 9-12 -VAG 1331/1-, see equivalent → Anchor |

| t | Insert e/c 17 terminal -V.A.G 1331/6-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

WARNING

WARNING Caution

Caution