Leon Mk1

| Repairing valve gear |

Note!

Note!| t | Cylinder heads which have cracks between the valve seats or between a valve seat insert and the spark plug thread can be used further without reducing service life, provided the cracks do not exceed a maximum of 0.3 mm in width, or when no more than the first 4 turns of the spark plug thread are cracked. |

| t | When new bucket tappets have been installed the engine must not be started for about 30 minutes. (Otherwise valves will contact pistons.) Then turn crankshaft two full revolutions. |

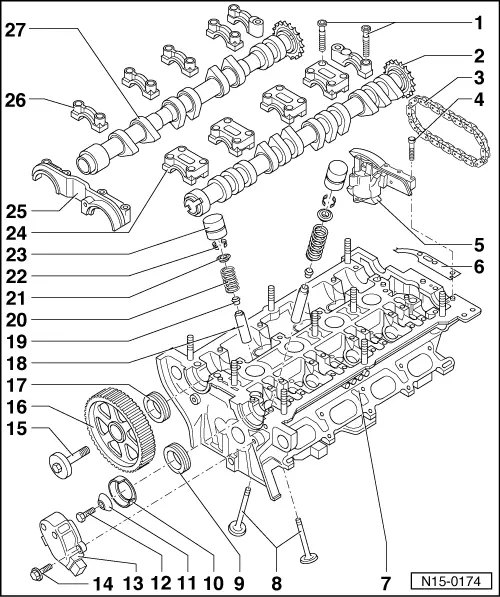

| 1 - | 10 Nm |

| 2 - | Inlet camshaft |

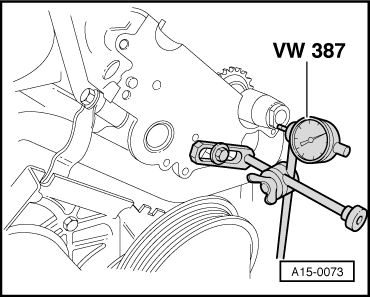

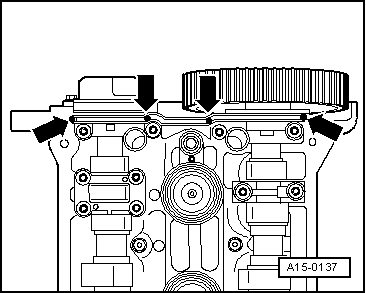

| q | Checking axial clearance → Fig.. |

| q | Removing and installing → Chapter. |

| q | Check radial clearance with plastigage, wear limit: 0.1 mm. |

| q | Runout: max. 0.01 mm. |

| 3 - | Drive chain |

| q | Before removing, mark direction of rotation (installation position) → Chapter, Removing and installing camshafts. |

| 4 - | 10 Nm |

| 5 - | Chain tensioner |

| q | Must seat on dowel sleeves. |

| q | Only rotate engine when chain tensioner is installed. |

| q | Secure with chain tensioner retainer -3366- before removing → Chapter, Removing and installing camshafts. |

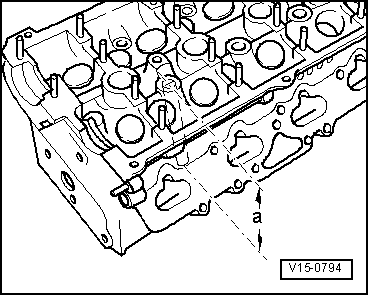

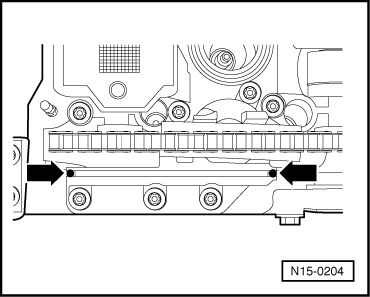

| q | Seal transitions between chain tensioner/cylinder head → Fig. |

| 6 - | Rubber/metal gasket |

| q | Replacement → Chapter, Removing and installing camshafts. |

| 7 - | Cylinder head |

| q | Removing and installing → Chapter. |

| q | Reworking valve seats → Chapter. |

| q | Reworking sealing surface → Fig.. |

| q | Sealing transition points → Fig. and → Fig.. |

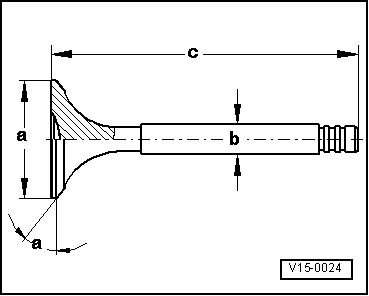

| 8 - | Valves |

| q | Do not rework, only lapping-in is permitted. |

| q | Valve dimensions → Fig.. |

| q | Exhaust valves with sodium filling: Observe disposal instructions → Fig.. |

| 9 - | Seal |

| q | Renewing → Chapter. |

| 10 - | Trim |

| q | For Hall sender. |

| q | When installing note fixing arrangement. |

| 11 - | Washer |

| q | Conical. |

| 12 - | 25 Nm |

| 13 - | Hall sender -G40- housing |

| q | Check Hall sender -G40- → Rep. Gr.28. |

| 14 - | 10 Nm |

| 15 - | 65 Nm |

| q | Use counterhold tool -3036- to loosen and tighten |

| 16 - | Camshaft pulley |

| q | Note installation position: the narrow web of camshaft pulley faces outwards and the TDC No. 1 cylinder marking is visible. |

| q | Note position when installing toothed belt → Chapter, removing, installing and tensioning toothed belt. |

| 17 - | Seal |

| q | Renewing → Chapter. |

| 18 - | Valve guide |

| q | Checking → Chapter. |

| 19 - | Valve stem oil seal |

| q | Renewing → Chapter. |

| 20 - | Valve spring |

| q | Removing and installing: |

| Cylinder head removed: With valve spring tool -3362- and press piece -3362/1-. |

| Cylinder head installed: → Chapter, Renewing valve stem oil seals |

| 21 - | Valve spring plate |

| 22 - | Cotters |

| 23 - | Bucket tappet |

| q | Do not interchange. |

| q | With hydraulic valve clearance compensation. |

| q | Checking → Chapter. |

| q | Store with cam contact surface downwards |

| q | Before installing, check camshaft axial clearance → Fig.. |

| q | Oil contact surface. |

| 24 - | Inlet camshaft bearing cap |

| q | Observe installation position and installation sequence → Chapter, Removing and installing camshaft. |

| 25 - | Double bearing cap |

| q | Must seat on dowel sleeves. |

| q | Lightly coat contact surface with sealing compound -AMV 174 004 01-, observe installation position and installation sequence → Chapter, Removing and installing camshaft. |

| q | Seal transition points between double bearing cap and cylinder head → Fig.. |

| 26 - | Exhaust camshaft bearing cap |

| q | Observe installation position and installation sequence → Chapter, Removing and installing camshaft. |

| 27 - | Exhaust camshaft |

| q | Checking axial clearance → Fig.. |

| q | Removing and installing → Chapter. |

| q | Check radial clearance with plastigage, wear limit: 0.1 mm. |

| q | Runout: max. 0.01 mm. |

|

|

Note!

Note!

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 26.9 | 29.9 |

| Ø b | mm | 5.963 | 5.943 |

| c | mm | 104.84...105.34 | 103.64...104.14 |

| α | ∠° | 45 | 45 |

Note!

Note!

|

|

|

|

|