Leon Mk1

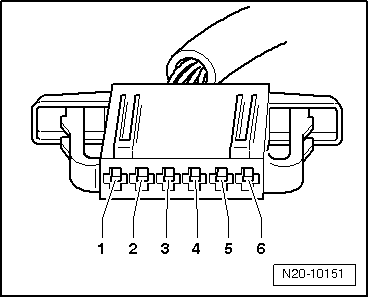

| Checking accelerator pedal position sender |

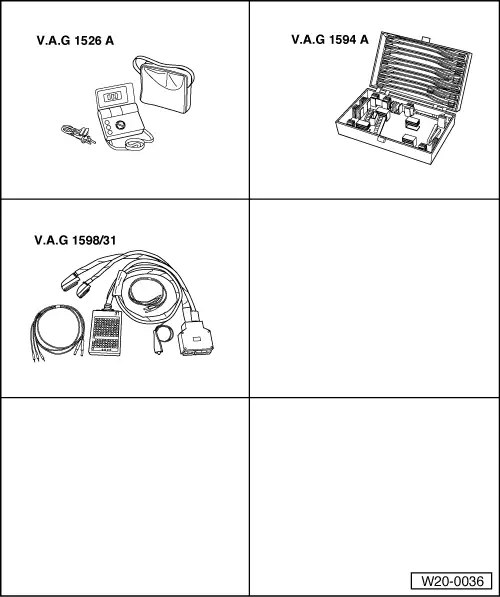

| Special tools and workshop equipment required |

| t | Hand multimeter -V.A.G 1526 A- or hand multimeter -V.A.G 1526C- |

| t | Auxiliary measuring set -V.A.G 1594 A- or auxiliary measuring set -V.A.G 1594C- |

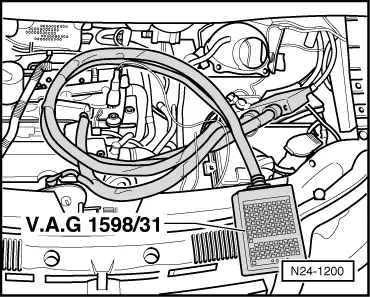

| t | Adapter lead, 121-pin -V.A.G 1598/31- |

|

|

|

|

|

|

|

Note!

Note!

Note!

Note!

|

|

|

|

|

|

|

|