Leon Mk1

| Piston, connecting rod, and casing: removing and installing |

| 1 - | Safety cotter pin |

| 2 - | Piston pin |

| q | If movement is sluggish, heat the piston to 60 °C |

| q | Remove and install with -T20019- |

| 3 - | Piston |

| q | Mark the fitting position and correspondence with respective casing/cylinder |

| q | The arrow on the piston head indicates the engine's turning direction (towards the camshaft side) |

| q | Install with casing to fit rings |

| q | Only install pistons of the same weight category (+ or - on the piston head) |

| q | Only available as a replacement part together with the casing |

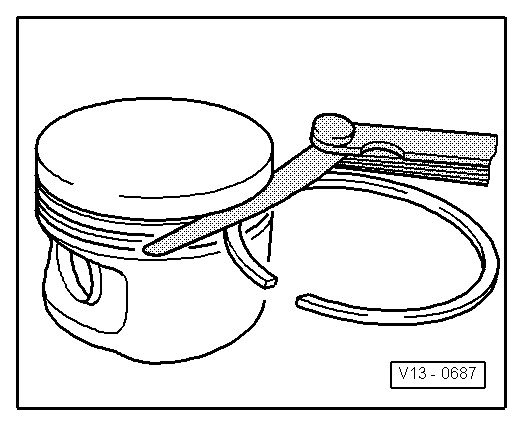

| 4 - | Piston rings |

| q | Stagger the cuts by 120° |

| q | Remove and install the compression rings using ring pliers |

| q | Carefully remove and install by hand the 3 piece oil scraper rings |

| q | The inscription “TOP” should must indicate the piston head |

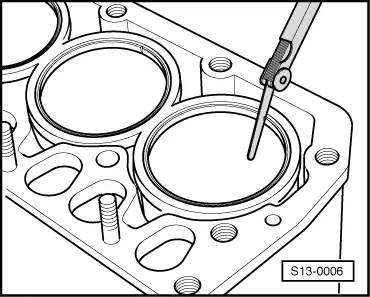

| q | Check the play between the ends of the rings → Fig. |

| q | Check the coupling play between the rings and the grooves in the piston → Fig. |

| 5 - | Connecting rod |

| q | Replacement part only available as a complete set (four rods) |

| q | Mark correspondence to cylinder → Item |

| q | Fitting position: The marks -B- must point towards the distribution |

| q | Axial guidance by piston |

| 6 - | Connecting rod caps |

| q | In the case of fractured or “cracked” connecting rods, the cap can only be fitted in one position and only on its corresponding connecting rod |

| 7 - | Connecting rod bolt, 20 Nm + 1/4 of turn (90°) |

| q | Renew |

| q | Lubricate the threads and the contact surface |

| q | In order to measure radial play, tighten to 20 Nm, without retightening |

| 8 - | Engine block |

| q | The surfaces where the casings will go must be clean and even |

| q | Remove dirt and grime from the surfaces only by cleaning; do not use sandpaper, scraper or the like |

| 9 - | Half bearings |

| q | Fit the centred half bearings |

| q | Do not interchange the used half bearings |

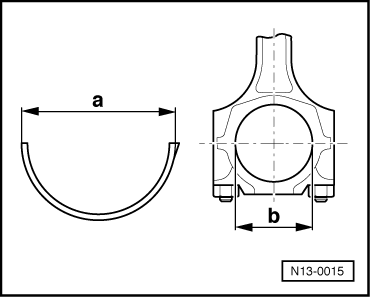

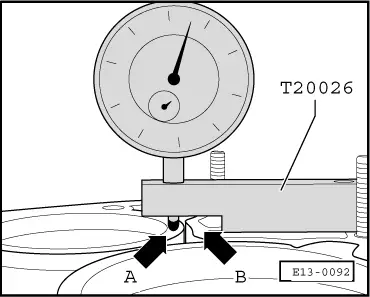

| q | Measure pre-tension → Fig. |

| q | Measure radial play with Plastigage: New: 0.020...0.061 mm Wear limit: 0.091 mm When measuring radial play do not turn crankshaft |

| 10 - | Washer |

| q | Renew |

| q | To correct the casing's pre-tension |

| 11 - | Casing |

| q | Observe the weight category (+ or - on the piston head) |

| q | Only available as a replacement part together with the the piston |

| q | Measure the pre-tension → Fig. |

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.20...0.50 | 1.0 |

| 2nd compression ring | 0.20...0.50 | 1.0 |

| Scraper ring | 0.40...1.40 | -- → Note |

|

|

|

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.04...0.08 | 0.15 |

| 2nd compression ring | 0.04...0.08 | 0.15 |

| Scraper ring | not measured | |

|

|

Note!

Note!

|

|