| –

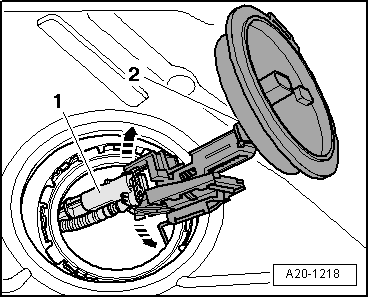

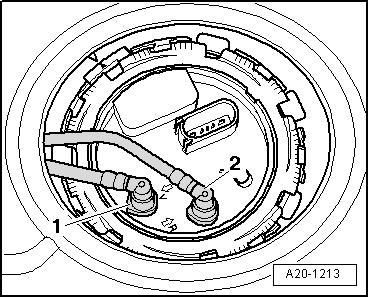

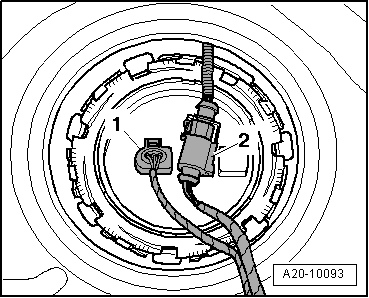

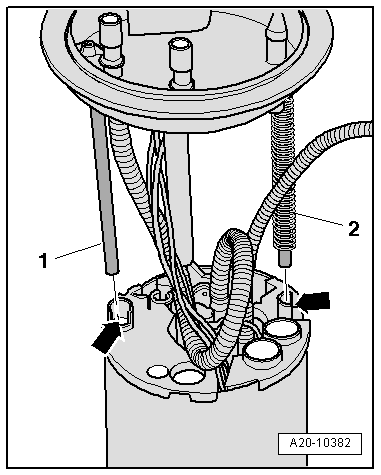

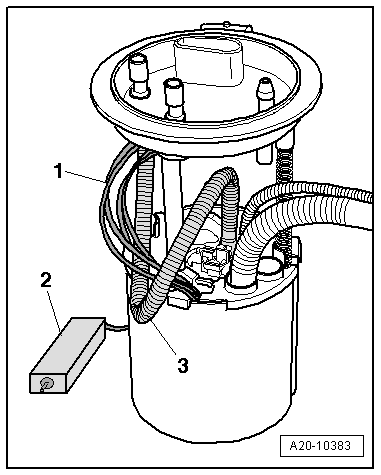

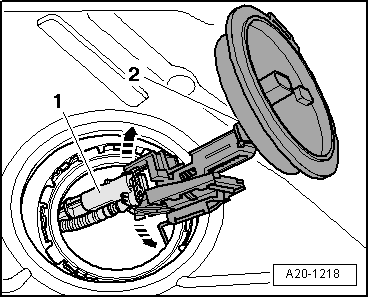

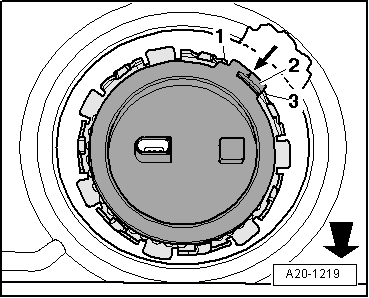

| Carefully pull the fuel level sender 2 -G169-- 2- with the spray jet -1-,removing them a little through the fuel tank opening. |

| –

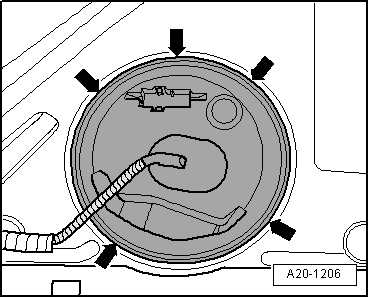

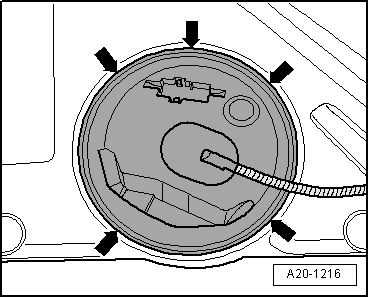

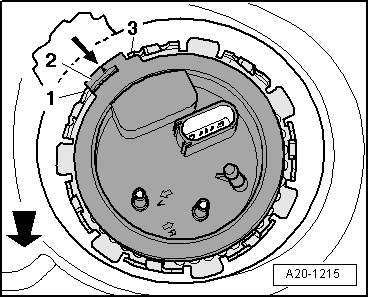

| Unclip the spray jet from the locking flange -arrows-. |

Note | On removing the fuel level sender 2 -G169-, make sure you do not bend its floater arm. |

| –

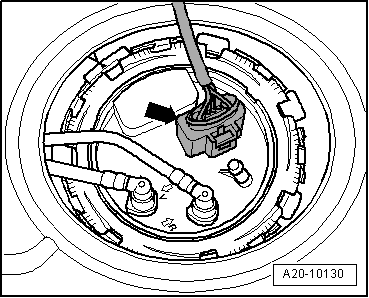

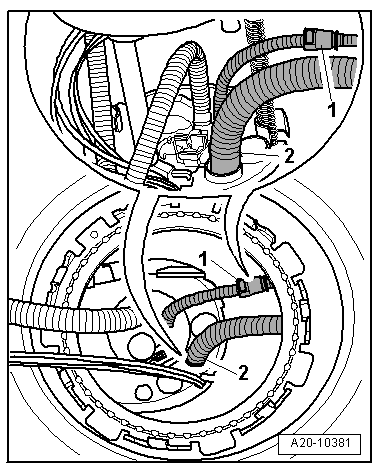

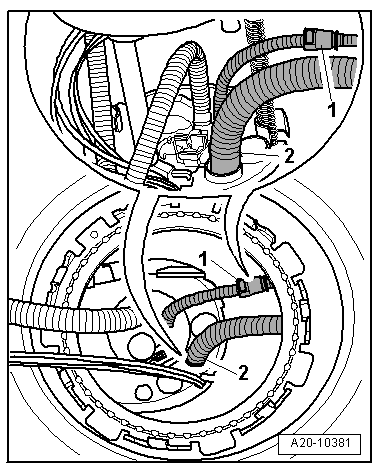

| On the vehicle left side, put your hand through the fuel tank opening and remove the nozzle together with the conduits pulling towards the left. |

| Installation is carried out in the reverse order; note the following: |

Note | Upon introducing the fuel level sender 2 -G169-, make sure you do not bend its floater arm. |

| –

| On the vehicle left side, insert the nozzle with the conduits via the fuel tank opening. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution