| –

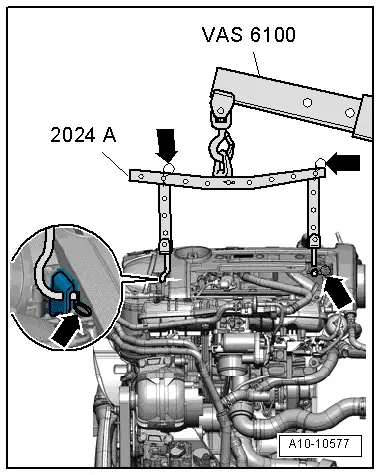

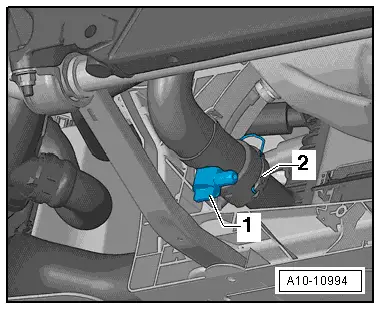

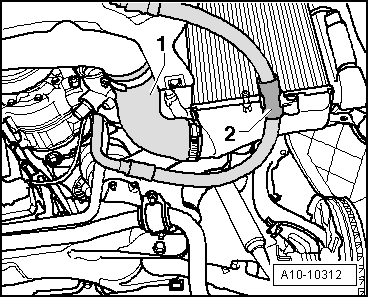

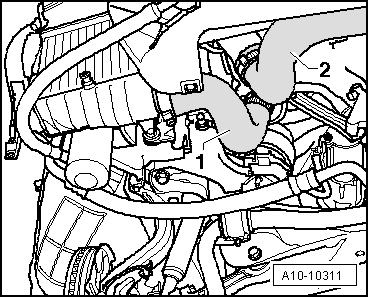

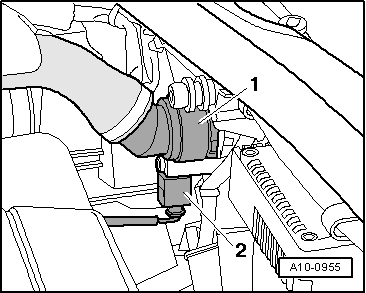

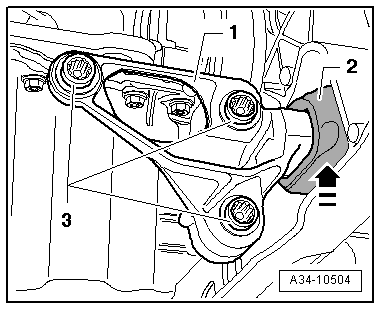

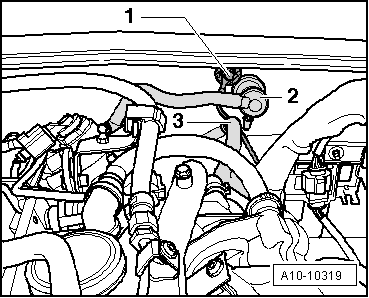

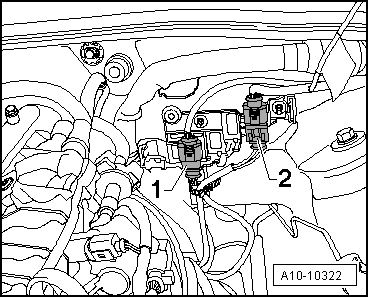

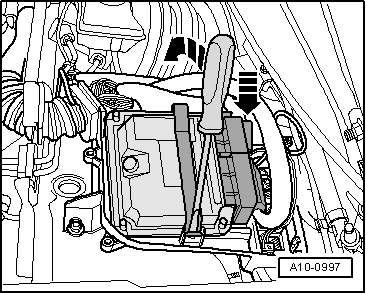

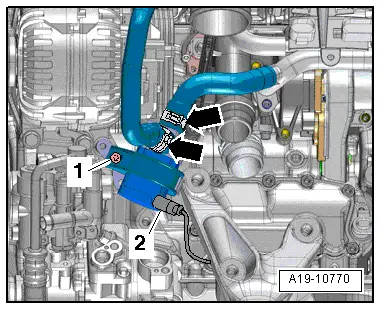

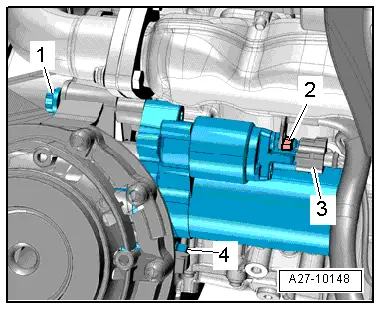

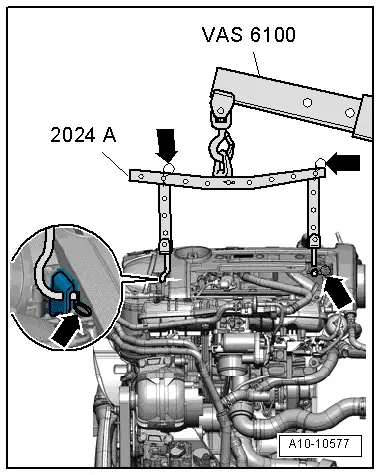

| Engage lifting tackle -2024A- on engine and workshop hoist -VAS 6100-. |

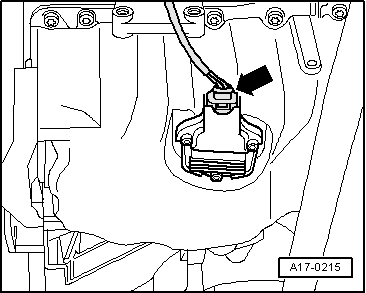

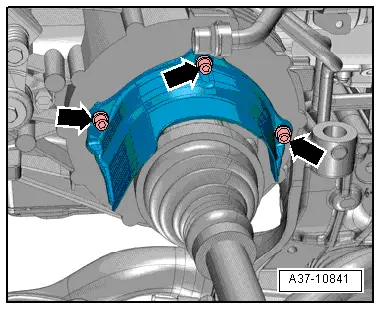

Note | For illustration purposes here shown with engine removed. |

| –

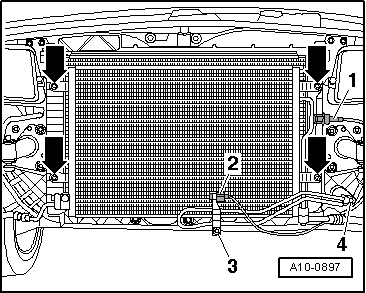

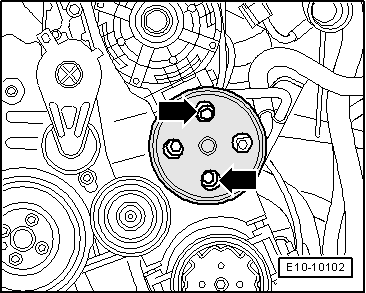

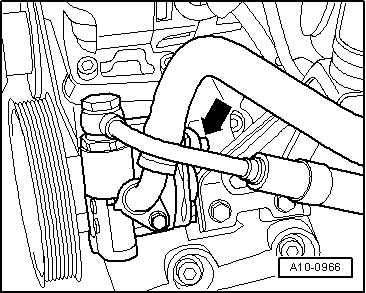

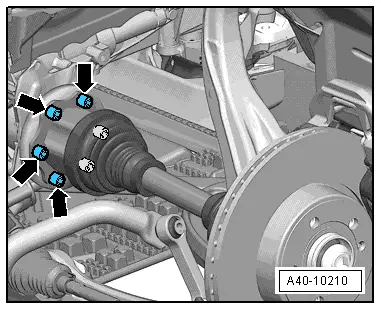

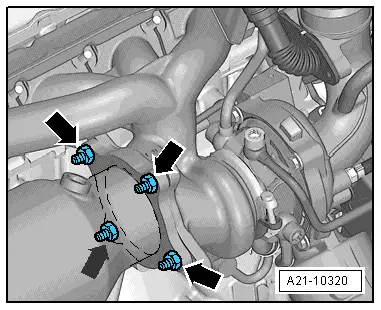

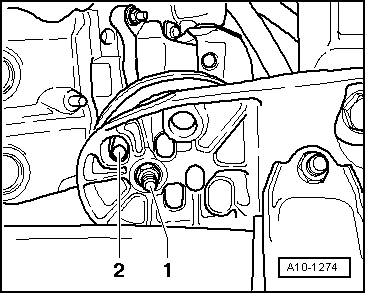

| Unscrew and remove the last connecting screw on the flange of the engine/gear. |

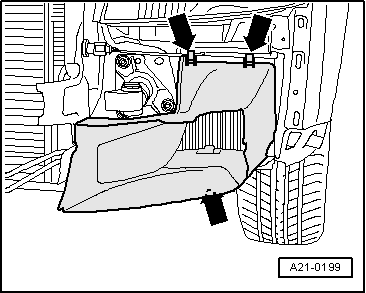

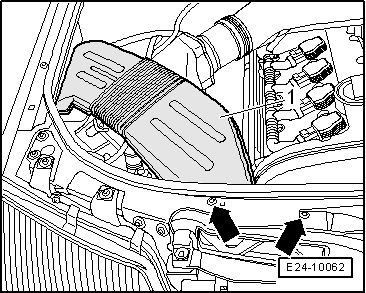

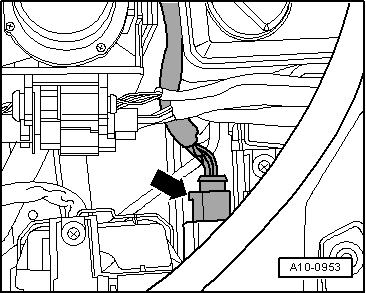

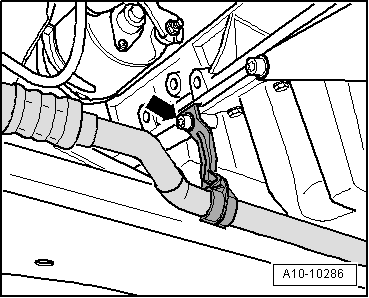

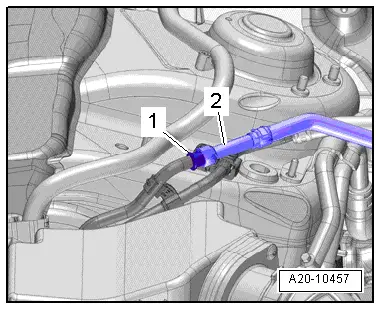

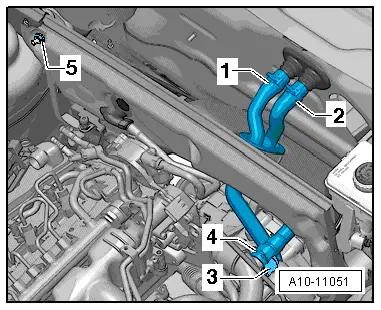

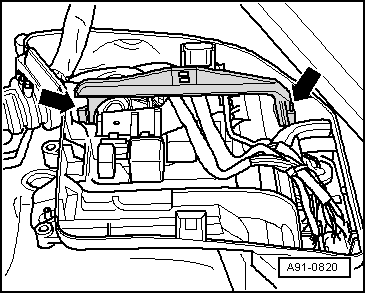

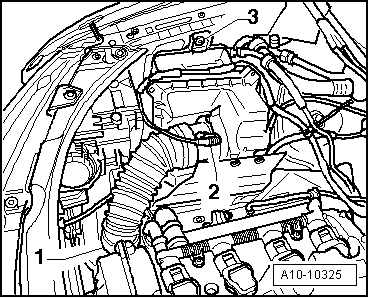

Caution | Danger of damage to hoses, pipes and wiring connections and to engine compartment. |

| t

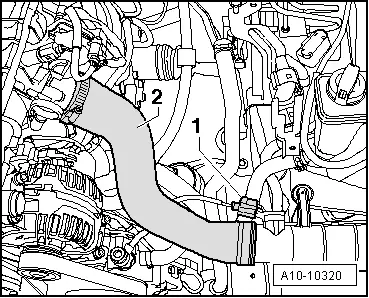

| Check that all hoses and cable connections between the engine, gearbox, subframe and body have been detached. |

| t

| Carefully guide engine out of engine compartment when lifting out. |

|

| –

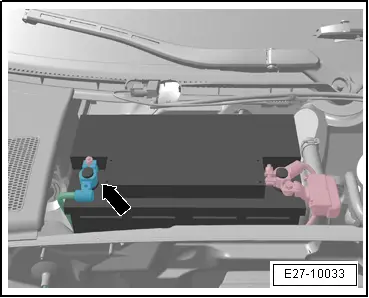

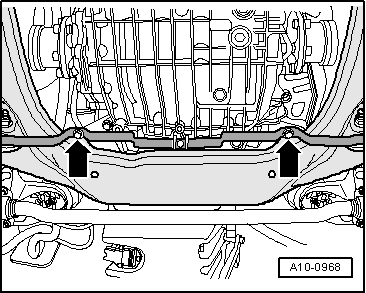

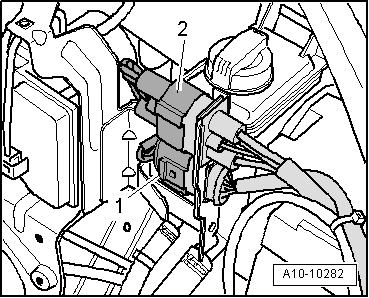

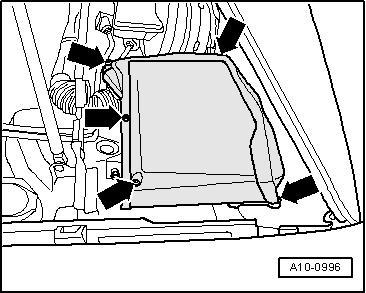

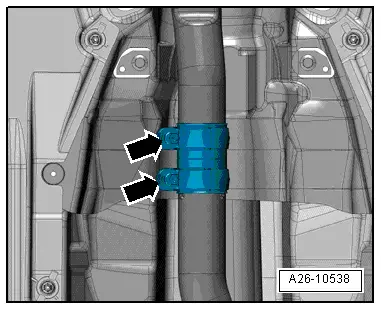

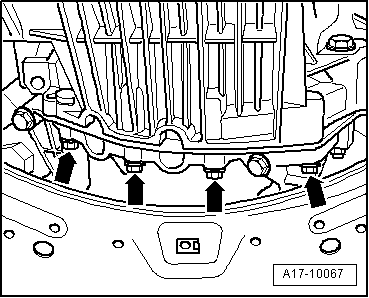

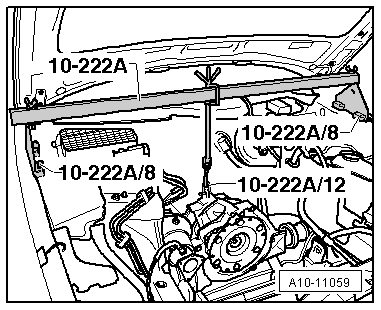

| Position hydraulic lifter upward until gearbox makes contact. |

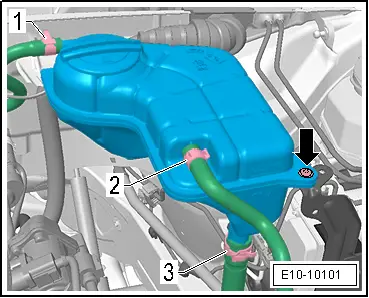

Note | Make sure no wires/pipes are damaged at the top on the bulkhead. |

| –

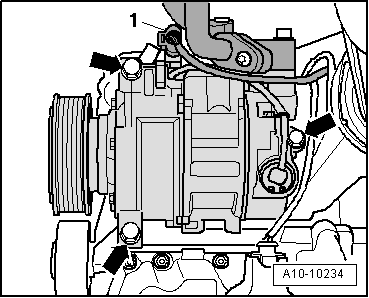

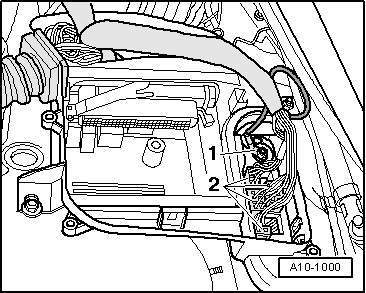

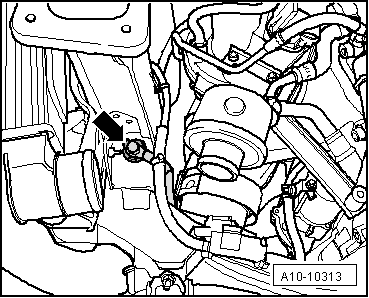

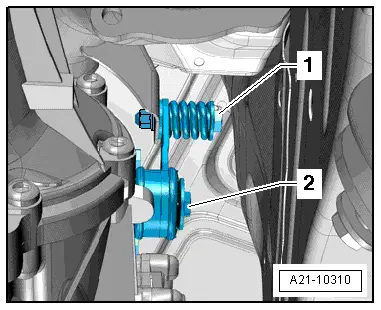

| Lift the engine with the garage crane -VAS 6100- until the engine bearing thread bolts are free. |

Note | t

| Check that all hoses and line connections between engine and body have been released. |

| t

| Guide »engine« carefully when removing to prevent damage to bodywork. |

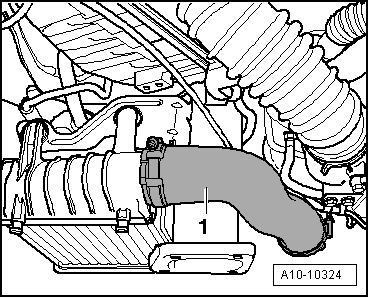

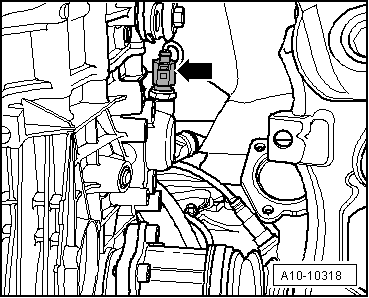

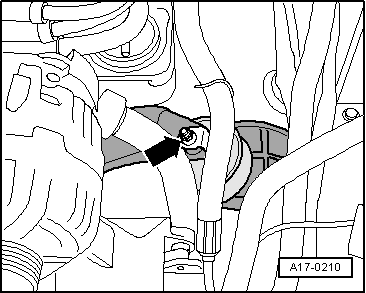

| Take special care that the starter is removed at the exact point when separating the engine from the gearbox. |

| –

| Detach engine from gearbox and lift engine forwards out of engine compartment. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution