| –

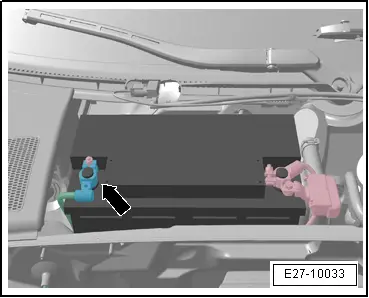

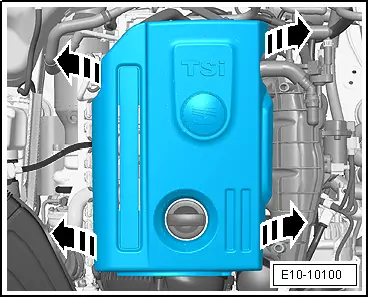

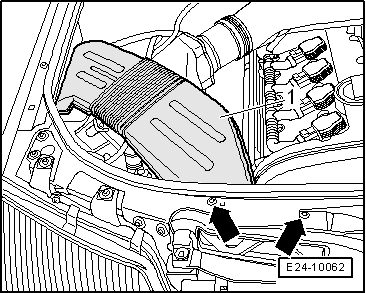

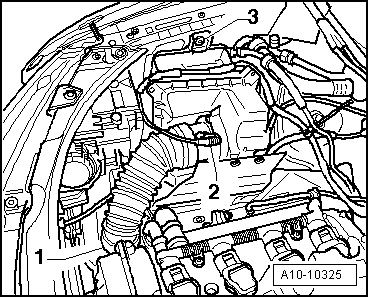

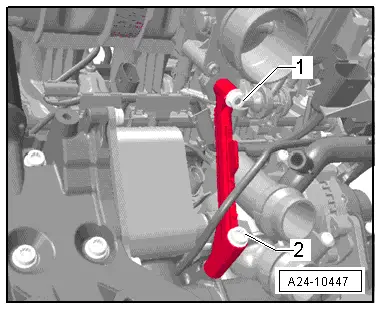

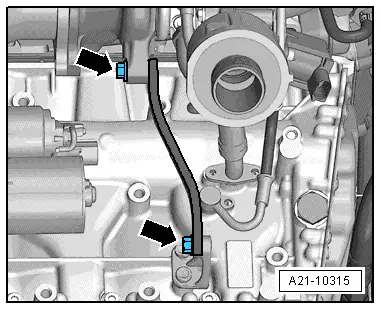

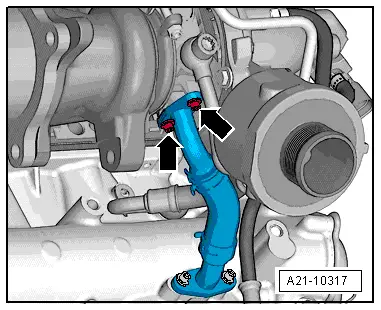

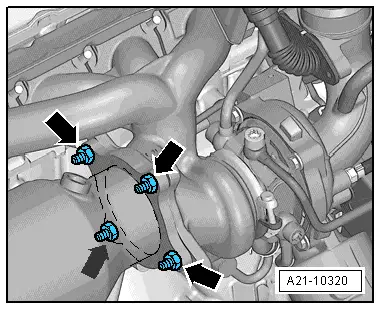

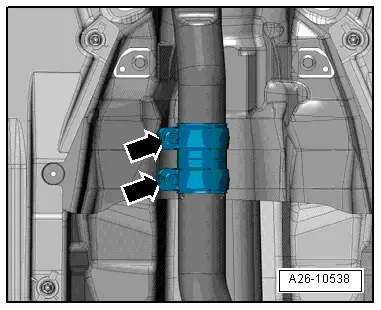

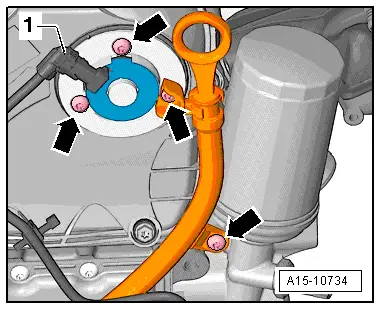

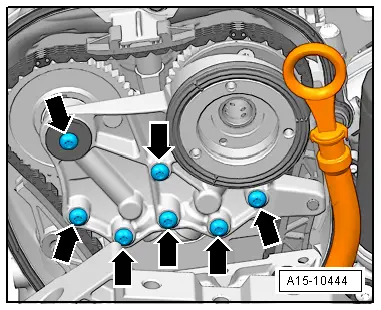

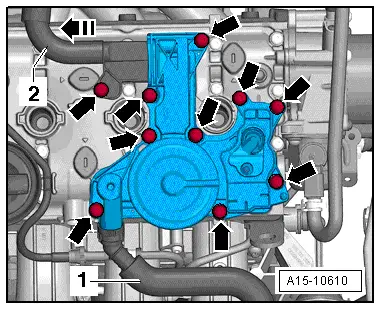

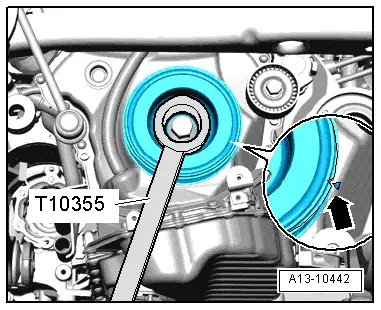

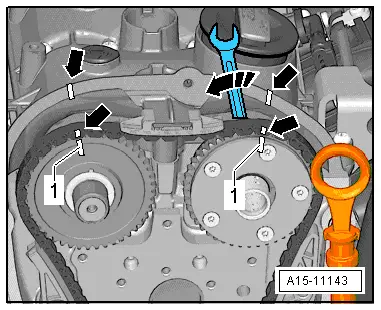

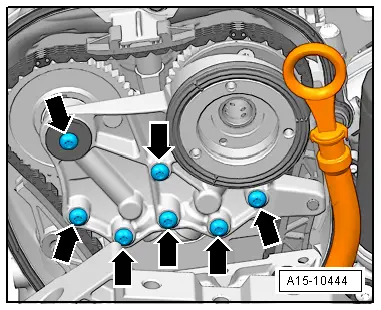

| Unscrew bolts -arrows-. |

| –

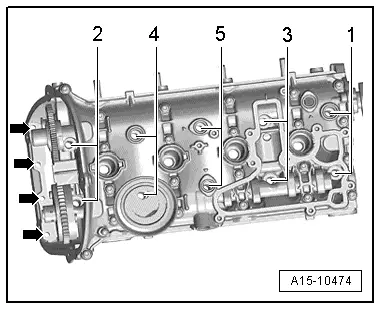

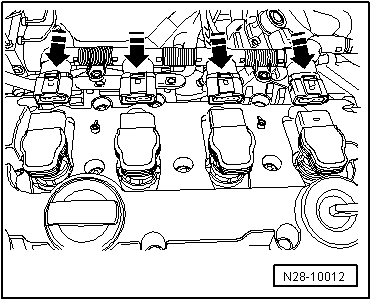

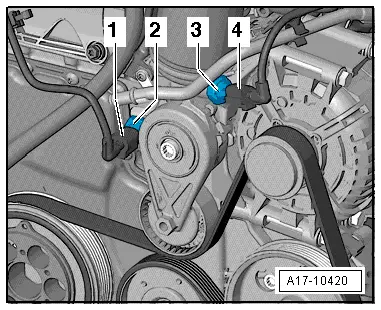

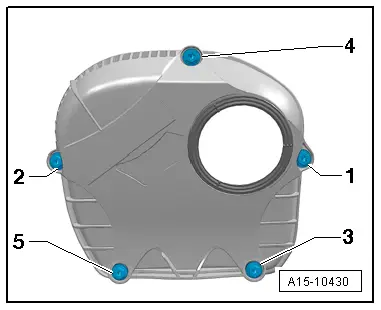

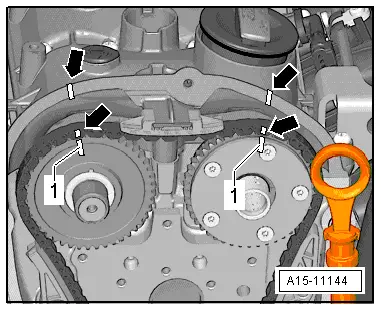

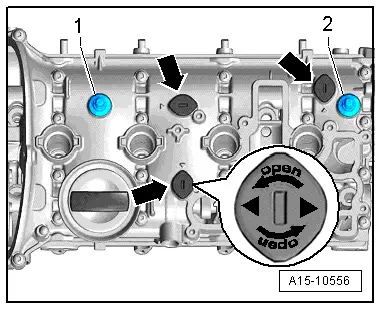

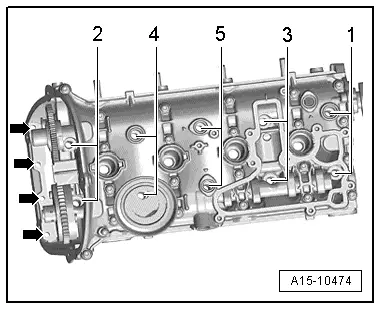

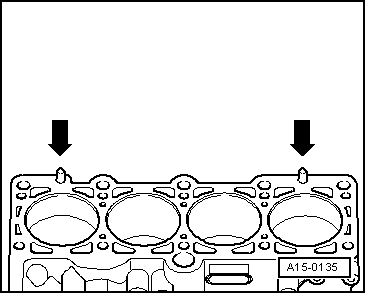

| Remove cylinder head bolts in the sequence -1 ... 5-. |

Note | t

| If necessary, use spanner to turn camshafts before removing cylinder head bolts. |

| t

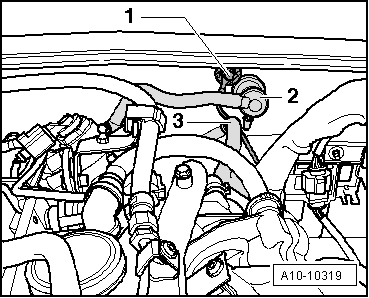

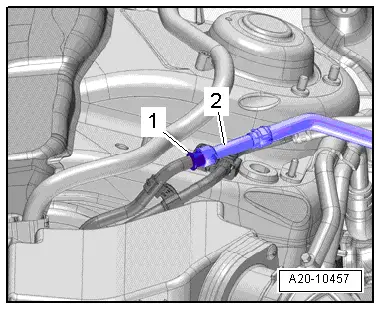

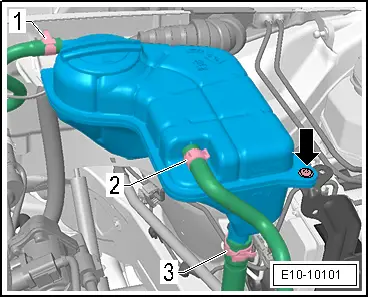

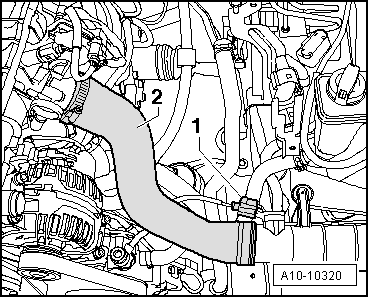

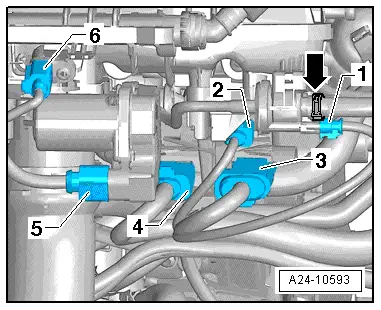

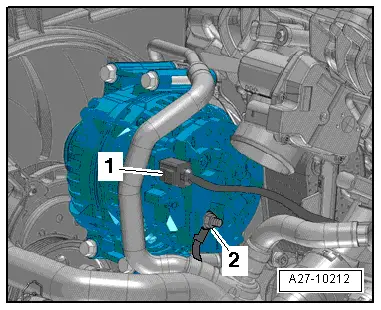

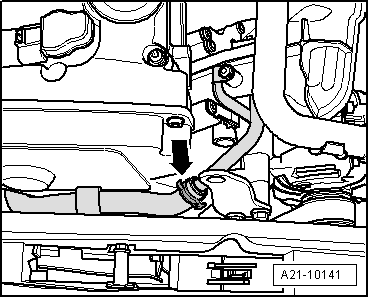

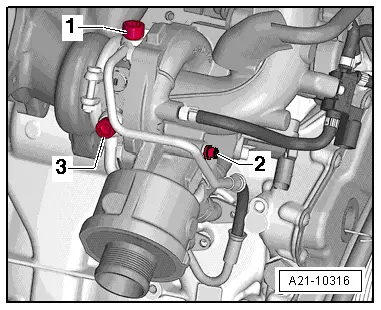

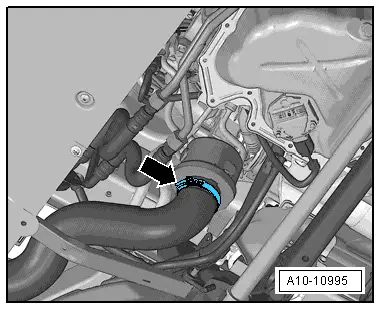

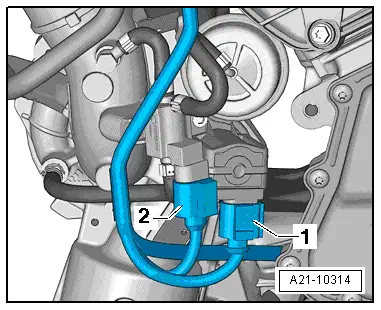

| Make sure all hoses/pipes and wiring on component are removed. |

| t

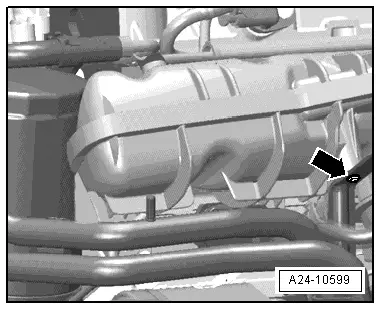

| Make sure tensioning rail and guide rail are not damaged when lifting off cylinder head. |

| –

| Remove the cylinder head. |

| –

| Place cylinder head onto soft surface (foam plastic). |

Caution | Risk of damaging the contact surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Risk of damage to the engine! |

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Ensure that cylinder head gasket seals properly: |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Risk of damaging the open valves! |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Replace the bolts tightened using goniometrics. |

| t

| Always replace seals, gaskets and self-locking nuts |

| t

| Take into account the different gasket pastes that should be used for the sealing surfaces and for the cylinder head bolts. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and coolant. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING