Leon Mk1

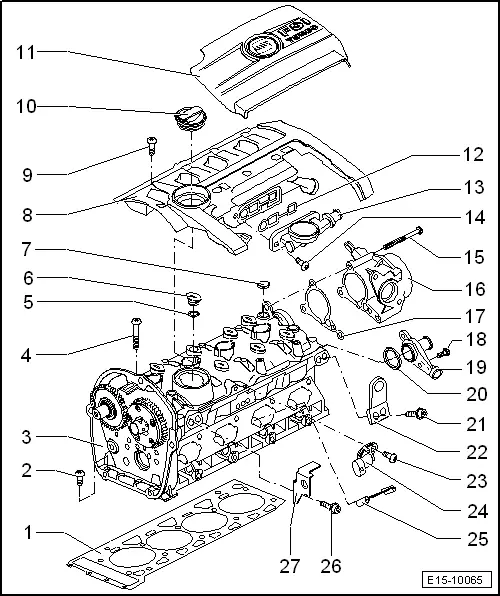

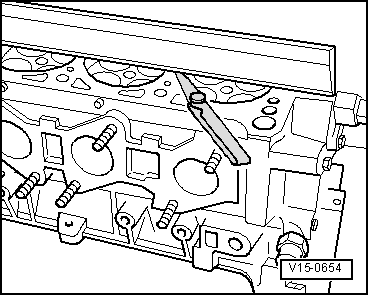

| 1 - | Cylinder head gasket |

| q | Replace |

| q | Note the fitting position: The component number faces towards the cylinder head |

| 2 - | Bolt. |

| q | Tightening sequence → Fig. |

| 3 - | Cylinder head |

| q | Removing and installing → Chapter. |

| q | Checking for distortion → Fig. |

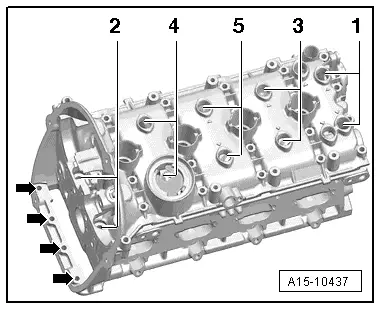

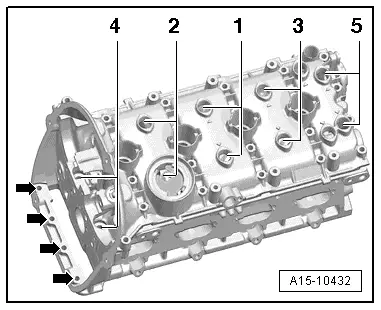

| 4 - | Cylinder head bolt |

| q | Replace |

| q | Correct sequence when slackening → Fig. |

| q | Note correct sequence when tightening → Fig. |

| 5 - | O ring |

| q | Replace |

| q | Lubricate with engine oil |

| 6 - | Plug |

| 7 - | O ring |

| q | Replace |

| q | Lubricate with engine oil |

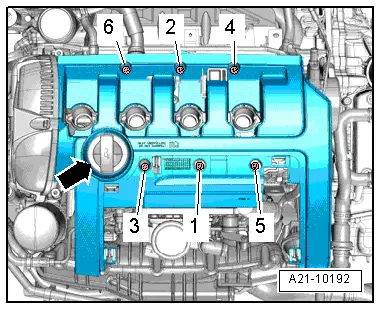

| 8 - | Cover with oil separator |

| q | Removing and installing → Chapter. |

| 9 - | Bolt. |

| q | Tightening sequence → Fig. |

| 10 - | Oil filler cap |

| q | With gasket |

| 11 - | Engine cover panel |

| q | Removing and installing → Chapter. |

| 12 - | Seal |

| q | Renew if damaged or leaking |

| 13 - | Valve body |

| 14 - | Bolt. |

| q | 4.2 Nm. |

| 15 - | Bolt. |

| q | 9 Nm. |

| 16 - | Vacuum pump |

| q | Removing and installing → Chapter. |

| 17 - | Seal |

| q | Replace |

| 18 - | Bolt. |

| q | 9 Nm. |

| 19 - | Joint mouth |

| 20 - | O ring |

| q | Replace |

| q | Lubricate with coolant |

| 21 - | Bolt. |

| q | 25 Nm. |

| 22 - | Transport plate |

| 23 - | Bolt. |

| q | 9 Nm. |

| 24 - | Hall sender -G40- |

| 25 - | Separating plate |

| 26 - | Bolt. |

| q | 25 Nm. |

| 27 - | Transport plate |

|

|

|

|

|

|

|

|

Note

Note