| Charge air cooling - exploded view |

Note | t

| The supercharger air system should not leak |

| t

| The flexible hose sleeves and the other turbocharger air system hoses must be free from oil and grease before the assembly. |

| t

| Apply a lubricant for rubbers free from silicone and oil on the leaking surface and on the joint ring. Do not use lubricant products containing silicone or oil. |

| t

| Replace the joint rings where damaged. |

| t

| On replacing the joint ring, place it on the turbocharger hose groove and check that the joint rings cover the entire groove perimeter to prevent damage. |

| t

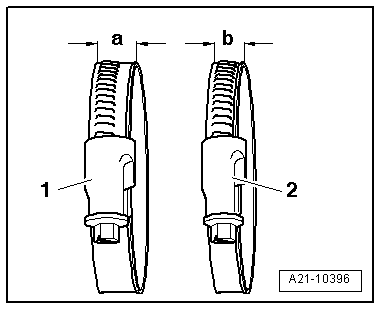

| To fix the turbocharger hoses to their connection sleeves safely, if already used clamps are used, their bolt threads should be sprayed with an anti-corrosion spray before the assembly. |

|

|

|

Note

Note