Note | t

| To carry out this work it will be necessary to disconnect battery earth strap. Therefore check whether a coded radio is fitted. Obtain anti-theft coding first if necessary. |

| t

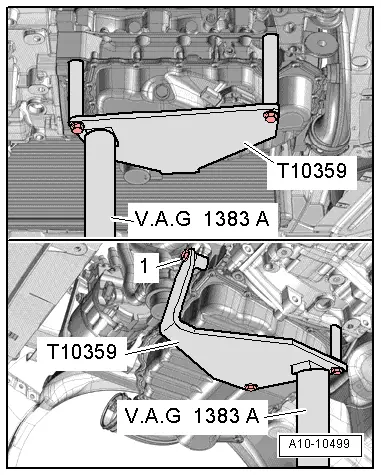

| The engine is removed from underneath together with the gearbox. |

| t

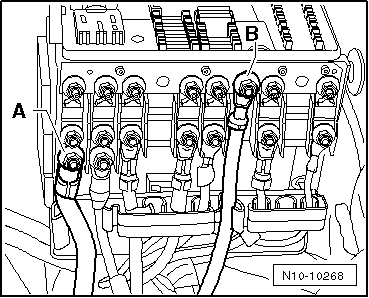

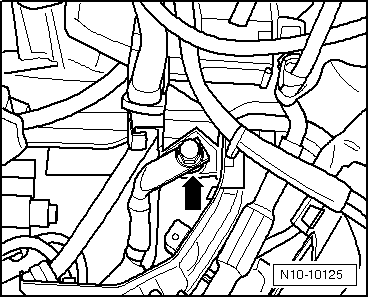

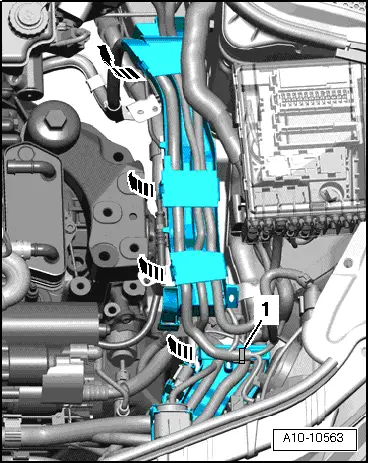

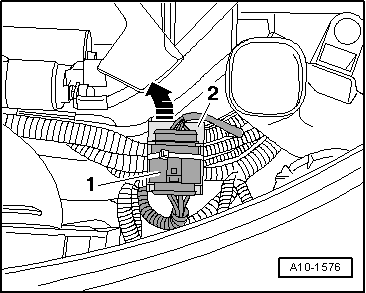

| All the cables, that are opened or cut during dismounting, should be placed again in the same location previously occupied during the fitting. |

Caution | Due to the enclosed spaces, observe the following during all assembly work, particularly in the engine compartment: |

| t

| Route lines of any kind so that the original routing can be restored. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING