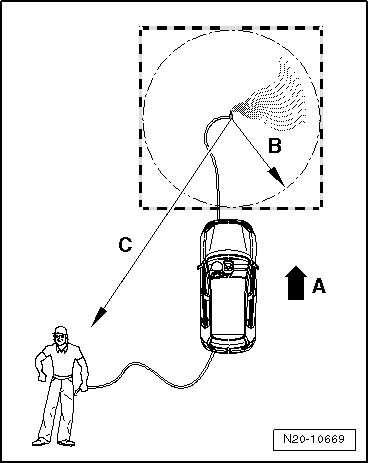

| The safety area must be cordoned off using warning bands and the access points must clearly indicate that there is a risk of explosions. |

WARNING | Liquified gas is heavier than air! |

| In the safety are, there should be no recesses, pits, channels, cellars or other rooms that are in lower areas where the gas is able to escape to. |

| There must be no active sources of ignition, such as open fire, electric sparks, electrostatic discharge and hot surfaces that may lead to the ignition of the liquified gas. |

|

Note | t

| Special attention must be paid to prevent gas from entering neighbouring buildings, such as through open doors and windows. The area must be freely accessible and well ventilated (not a backyard). |

| t

| The direction of the wind has to be considered: |

| Version for completely emptying the fuel tank (LPG) |

WARNING | Liquified gas tanks may not be emptied in closed rooms! |

| There is a risk of explosions or poisoning! |

| Fuel tanks must always be drained outside! |

|

| t

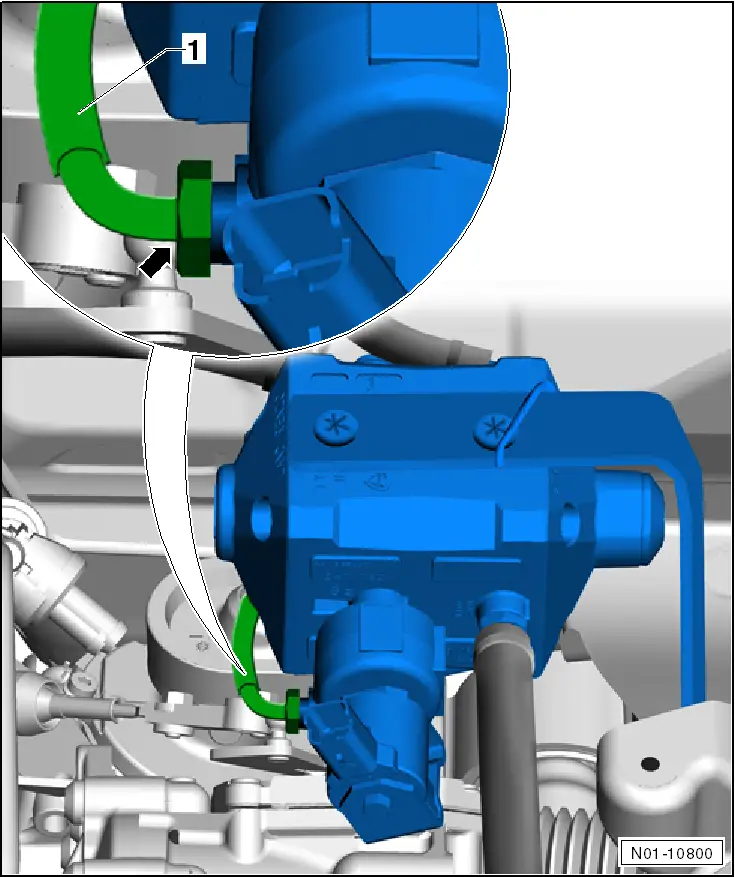

| Conventional tank draining systems or liquified gas fackel developed for LPG |

| t

| Venting the ambient air |

WARNING | Liquified gas can cause injuries. |

| The system is pressurised! |

| Meet the required measures: Wear protective gloves and safety goggles. |

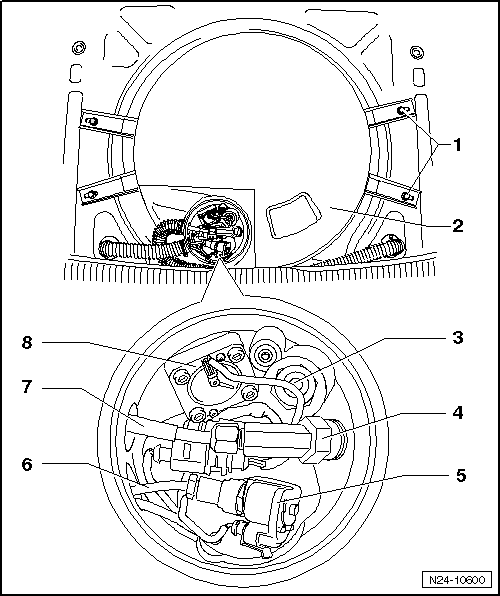

| Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection. |

|

|

|

|

Note

Note Note

Note

Note

Note

WARNING

WARNING Note

Note