Leon Mk1

| Crankshaft: disassembly and assembly |

Note!

Note!| t | The cylinder block will be fitted with the correct thickness bearing shells at the factory. The thickness will be indicated using points of varying colours |

| t | For assembly, the engine must be secured to the -AR2204A- assembly stand with the -T20082- engine bracket. |

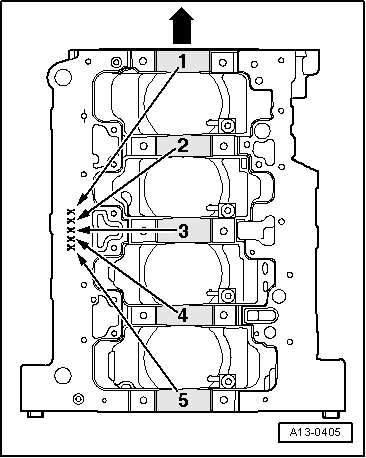

| 1 - | Half bearing 1, 2, 4 and 5 |

| q | For cylinder block with oil groove |

| q | Do not mix up used bearing shells (mark them) |

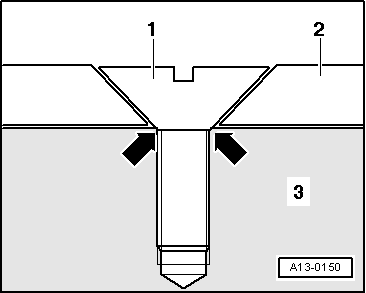

| q | Only use new half bearings that are marked with the same colours as those being replaced → Fig. |

| 2 - | Cog wheel for chain |

| q | For oil pump drive |

| 3 - | Half bearing |

| q | For bearing cap without oil groove |

| q | Do not mix up used bearing shells (mark them) |

| 4 - | Thrust washers |

| q | For cylinder block, bearing 3 |

| q | Note fixing arrangement |

| 5 - | 65 Nm + 1/4 turn (90°) |

| q | Replacement |

| q | Tighten to 65 Nm when measuring radial clearance |

| 6 - | Bearing caps |

| q | Bearing cap 1: pulley side |

| q | Bearing cap 3: with rebates for the thrust washers |

| q | Cylinder block bearing shell rims and bearing cap must coincide |

| 7 - | 10 Nm + 1/4 turn (90°) |

| q | Replacement |

| q | Each time that the bolts are loosened, the generator wheel must be replaced → Fig. |

| 8 - | Sender wheel |

| q | For engine speed sender -G28- |

| q | Can only be fitted in one position (the holes are offset) |

| q | Each time that the bolts are loosened, the generator wheel must be replaced |

| q | Removing and fitting → Fig. |

| 9 - | Crankshaft |

| q | Axial play: |

| q | new: 0,07 … 0,23 mm |

| q | Wear limit: 0,30 mm |

| q | Measure the radial play using a Plastigage |

| q | New: 0,02 … 0,04 mm |

| q | Wear limit: 0,15 mm |

| q | Do not rotate the crankshaft when checking the radial clearance |

| q | Do not rotate the crankshaft when checking the radial clearance |

| 10 - | Half bearing 3 |

| q | For cylinder block with oil groove |

| q | For bearing cap without oil groove |

| q | Do not mix up used bearing shells (mark them) |

| q | Only use new half bearings that are marked with the same colours as those being replaced → Fig. |

|

|

| Letters on the cylinder block | Colour of bearing shell | |

| S | = | black |

| R | = | red |

| G | = | yellow |

Note!

Note!

|