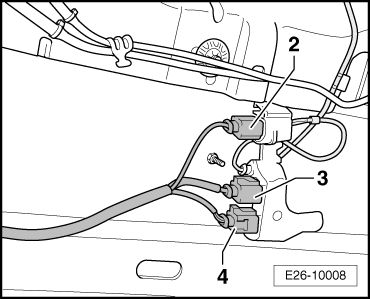

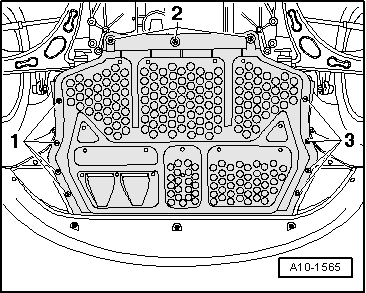

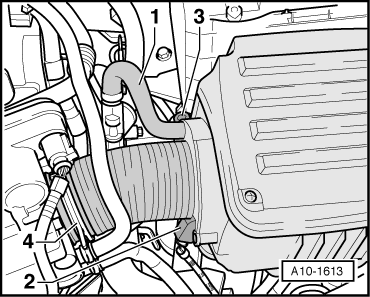

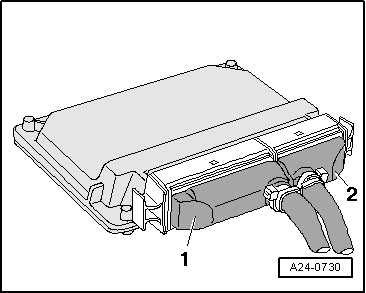

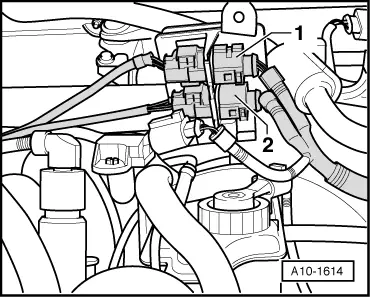

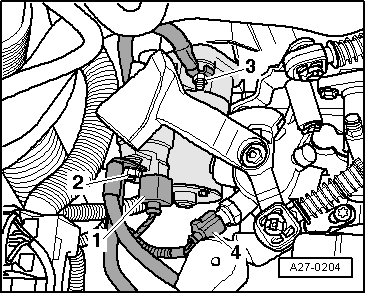

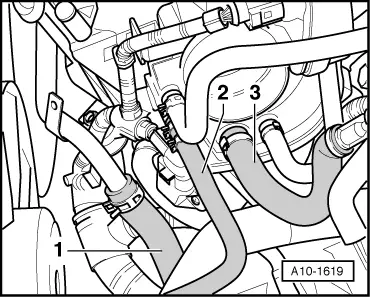

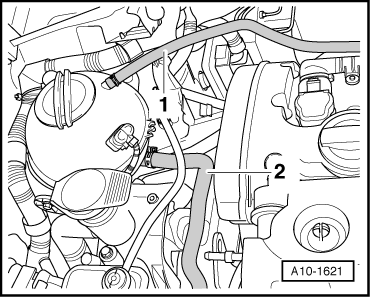

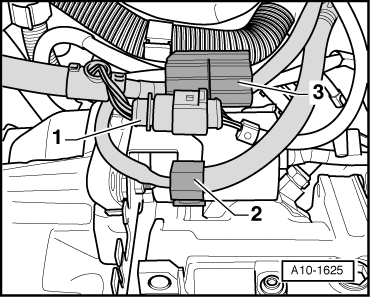

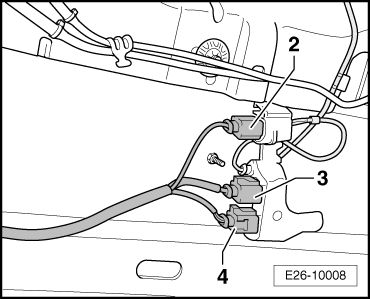

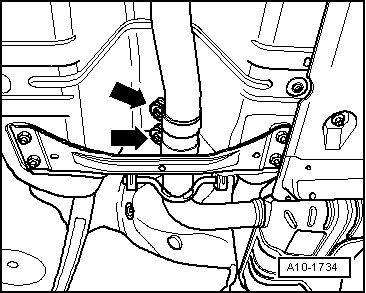

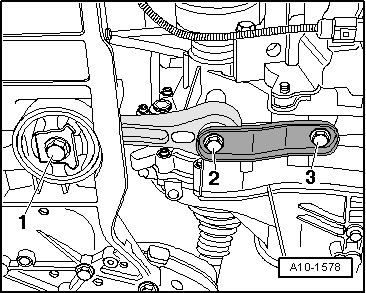

| Before detaching the connectors of the lamda probes, mark the pairs, to avoid exchanging parts when reassembling ( the following diagram shows the position of the connectors for engine code BLR). |

| –

| Detach the connector (grey) -2- for lambda probe III behind the catalyser -G287- with heating of lamda probe 3, behind the catalyser -Z64- and leave the cable bare. |

| –

| Detach the connector (brown) -3- for lambda probe behind the catalyser -G130- with heating of lamda probe 1, behind the catalyser -Z29- and leave the cable bare. |

| –

| Detach the connector (black) -4- for lamda probe II behind the catalyser -G131- with heating of lamda probe 2, behind the catalyser -Z30- and expose the cable. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING