WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route all the various lines (e.g. for fuel, hydraulics, active carbon filter system, coolant, refrigerant, brake fluid and vacuum pipes and hoses) and electrical wiring so that the original positions are restored. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

Note | t

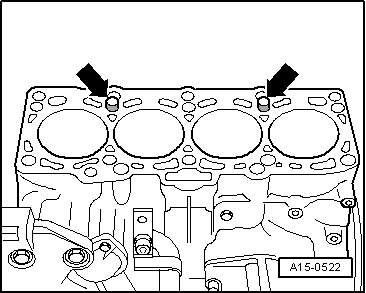

| Carefully remove any remains of sealant from the cylinder head and cylinder block. Ensure that no scoring or scratching is produced. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

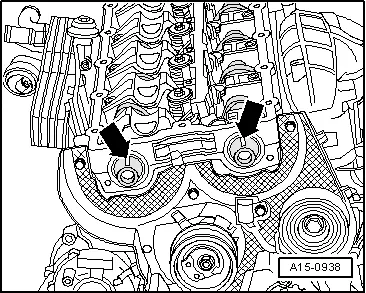

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| t

| Renew cylinder head bolts. |

| t

| When fitting, replace the self-locking nuts and bolts. |

| t

| Renew bolts which have a specified tightening angle, as well as seals and gaskets. |

| t

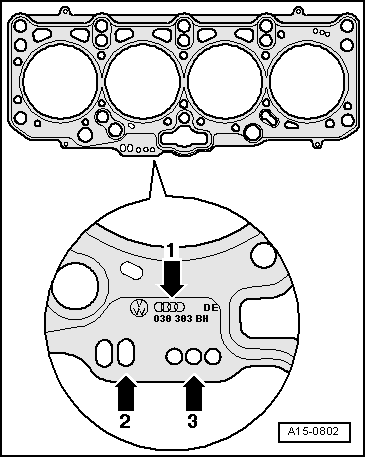

| Do not remove the new gasket from its packaging until just before fitting. |

| t

| Handle gasket extremely carefully. Damaging the silicone layer or the indented area will lead to leaks. |

| t

| When fitting a new cylinder head with the camshafts fitted, the contact surfaces between the roller rocker arms and the cam contact surfaces must be oiled following the fitting of the cylinder head. |

| t

| The plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| t

| Secure all hose connections with the correct hose clips (same as original equipment) → Parts catalogue. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING