Leon Mk1

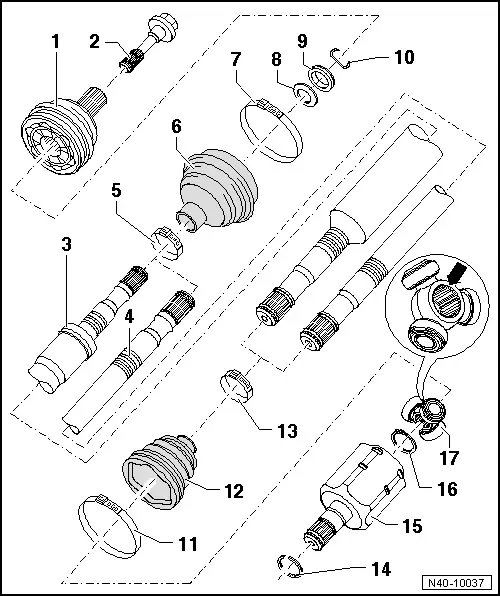

| Drive shaft with → tripod type joint AAR2600i - Assembly overview |

| 1 - | Outer constant velocity joint |

| q | Always replace completely |

| q | Removing → Fig. |

| q | Installation: insert onto the complete half-shaft by tapping with a plastic mallet, until the securing ring is decompressed |

| q | check → Chapter |

| 2 - | Bolt. |

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

| q | Hexagon bolt = 200 Nm + 180° further |

| q | Loosening and tightening the hex bolt → Chapter |

WARNING

WARNING

|

| q | Replace after each removal |

| 3 - | Right hand driveshaft |

| 4 - | Left hand driveshaft |

| 5 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 6 - | Dustguard for constant velocity joint |

| q | Ensure that there is no damage or cracks from friction |

| q | Material: → Hytrel (polyester elastomer) → Spare parts catalogue |

| 7 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 8 - | Dished spring |

| q | Installation position → Fig. |

| 9 - | Thrust washer |

| q | Installation position → Fig. |

| 10 - | Circlip |

| q | Replace after each removal |

| q | Fit into the groove on the complete half-shaft |

| 11 - | Clamp |

| q | Replace after each removal |

| q | Tension using the pliers for spring-type clips -V.A.G 1275- |

| 12 - | Boot for triple roller joint |

| q | Ensure that there is no damage or cracks from friction |

| 13 - | Clamp |

| q | Replace after each removal |

| q | Tension using the pliers for spring-type clips -V.A.G 1275- |

| 14 - | Circlip |

| q | Replace after each removal |

| 15 - | Joint body |

| 16 - | Circlip |

| q | Replace after each removal |

| q | Insert into the driveshaft groove using the pliers -VW 161 A- |

| 17 - | Triple roller star with rollers |

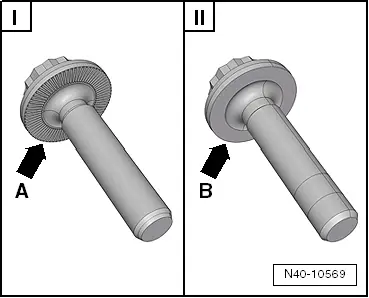

| The chamfer -arrow- points towards drive shaft splines. |