Note | During disassembly and assembly work, take care that the rubber bellow of the ball joint is not damaged. Where necessary, protect the rubber bellow of the ball joint against damaged. |

| –

| Remove the steering knuckle together with the traverse swinging arm ball joint. |

| –

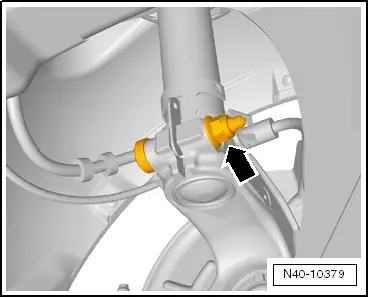

| Remove the outer constant-velocity joint of the propeller shaft from the wheel hub. Use extractor -T20001A -, if necessary. |

| –

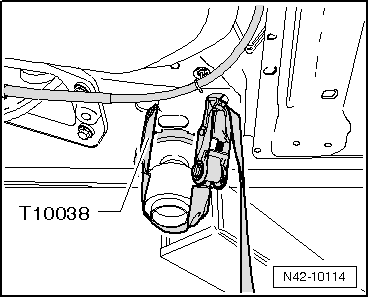

| Tie the half shaft to the chassis using a wire. |

Caution | The drive shaft must not hang down. Otherwise, the interior articulation will be damaged by excessive bending. |

|

| –

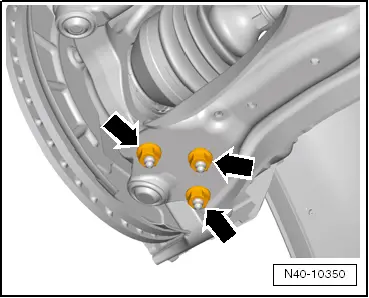

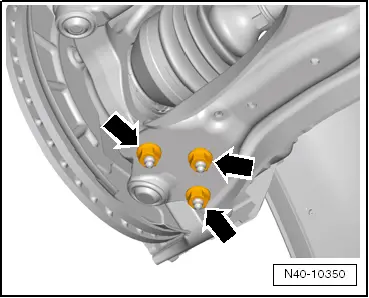

| Rebolt the ball joint to the traverse swinging arm. |

| –

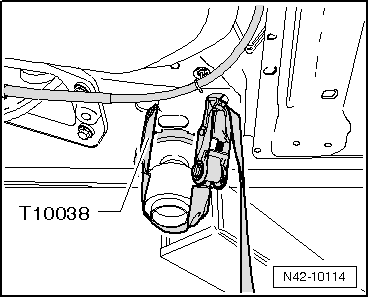

| Remove the hydraulic jack -V.A.G 1383 A- from below the wheel hub. |

WARNING | t

| Do not raise or lower vehicle while engine and gearbox jack -V.A.G 1383 A- is positioned under the vehicle. The vehicle could slip of the platform. |

| t

| Do not leave engine and gearbox jack -V.A.G 1383 A- under vehicle for longer than necessary. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note