Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||||

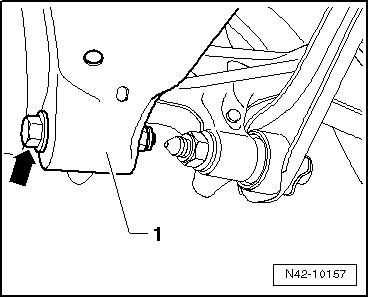

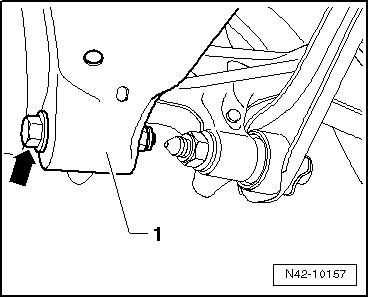

Lower transverse link to wheel bearing housing

| 90 Nm + 90° | ||||

Lower transverse link to subframe

| 95 Nm | ||||

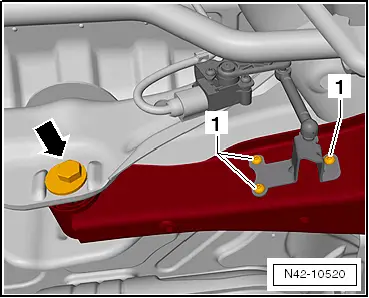

| Rear left vehicle level sender -G76- to lower transverse link | 5 Nm |