| Carry out the following work: |

Note | t

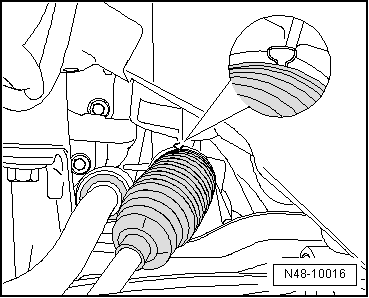

| Moisture and dirt will enter the steering box if the rubber boot is defective. It should be possible to feel a film of lubricant on and around the teeth of the steering rack. Renew steering box if no film of lubricant can be felt. |

| t

| The steering box must be replaced. |

| t

| In the event of corrosion. |

| t

| In the event of damage. |

| t

| In the event of excessive wear |

| t

| In the event of soiling on the steering rack. |

| –

| Turn steering wheel to straight-ahead position. |

| –

| Mark position of nut on track rod. |

| –

| Clean outside of steering box in vicinity of boot. |

| No dirt must be allowed to enter the steering box through a defective rubber boot during this operation. |

| –

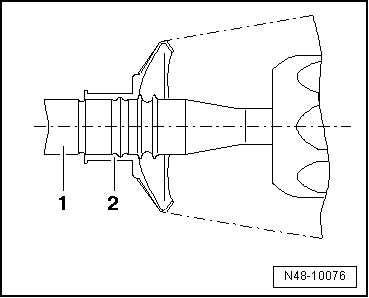

| Pull boot off steering box housing and track rod. |

Note | t

| Renew complete steering box if there are signs of corrosion, damage, wear or dirt on the steering rack. |

| t

| The complete steering box must also be renewed if there is no visible lubricating film on the steering rack. |

Caution | Do not grease steering rack. |

|

| –

| Turn steering wheel to straight-ahead position. |

| –

| Fit new hose clips and rubber boot onto track rod. |

| –

| Lightly lubricate sealing surface between boot and track rod with grease -G 052 168 A1- (from repair kit Fuchs Renolit JP1619). |

|

|

|

Note

Note Note

Note

Caution

Caution