Leon Mk1

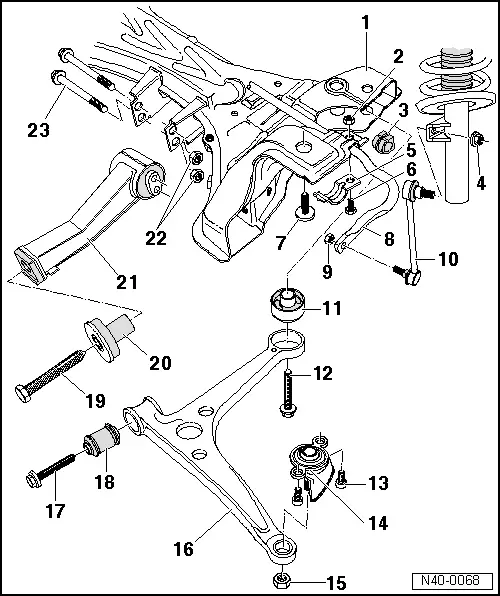

| I - Assembly overview - subframe, anti-roll bar, lower wishbone up to model year 2000 |

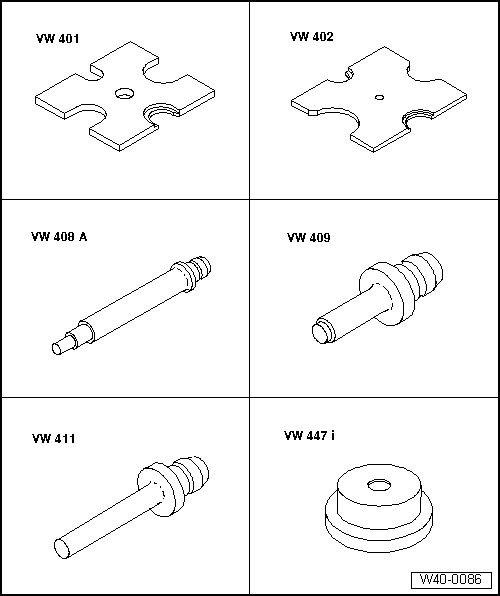

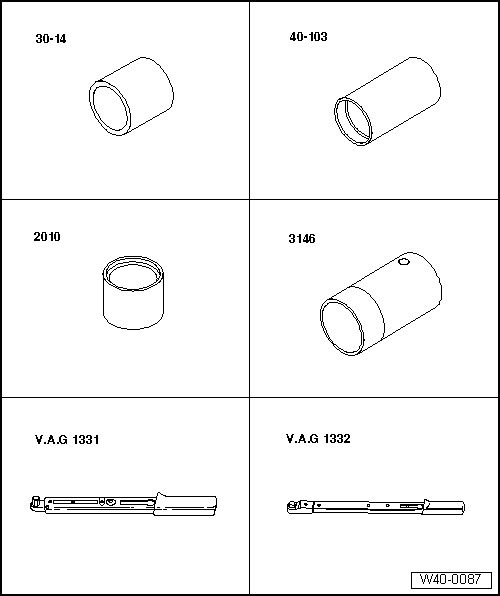

| Special tools and workshop equipment required |

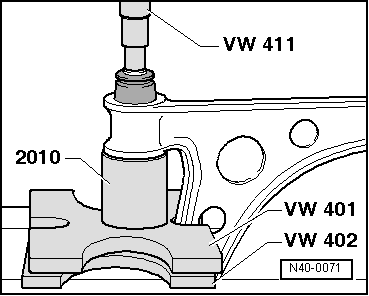

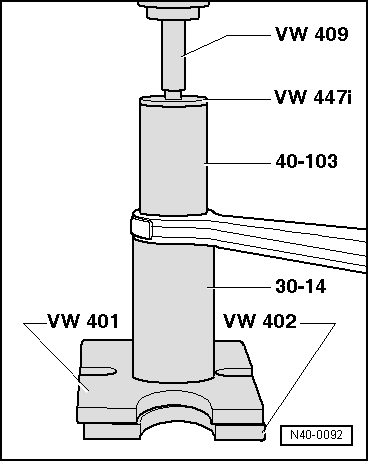

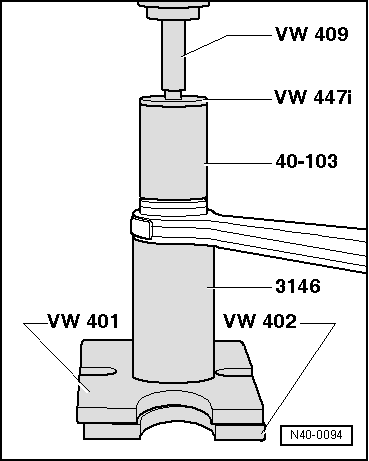

| t | Press plate -VW 401- |

| t | Press plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 409- |

| t | Press tool -VW 411- |

| t | Thrust plate -VW 447 i- |

| t | Tube -30-14- |

| t | Support -40-103- |

| t | Tube -2010- |

| t | Tube -3146- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

Note

Note| t | If a vehicle has to be moved after removing the drive shaft, first install outer joint and tighten to 50 Nm otherwise the wheel bearing will be damaged. |

| t | It is not permitted to carry out welding and straightening operations on load bearing suspension components or those components which locate the wheels. |

| t | Always renew self-locking nuts. |

| t | Always renew corroded nuts and bolts. |

| 1 - | Subframe |

| After installing check position of steering wheel during a test drive. |

| If steering wheel is not in straight ahead position the front axle toe must be checked and if necessary adjusted! |

| 2 - | Hexagon nut |

| q | 55 Nm |

| 3 - | Rubber bush |

| 4 - | Nut |

| q | 100 Nm |

| q | Self-locking |

| q | Renew each time after removing. |

| 5 - | Clamp |

| 6 - | Hexagon bolt |

| 7 - | Hexagon bolt |

| q | M14 x 1.5 x 65 |

| q | 150 Nm and turn 90° further. |

| q | Renew each time after removing. |

| 8 - | Anti-roll bar |

| q | Removing and installing → Chapter. |

| 9 - | Nut |

| q | 100 Nm |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| 10 - | Coupling rod |

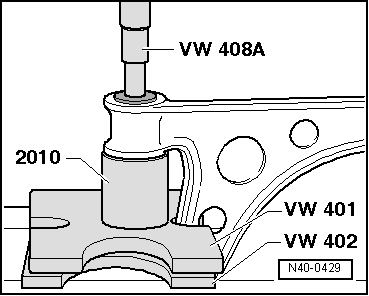

| 11 - | Rear wishbone mounting |

| q | Pressing out → Fig.. |

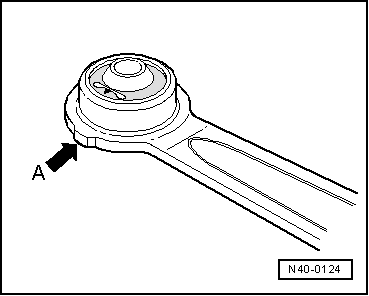

| q | Installation position → Fig.. |

| q | Pressing in → Fig.. |

| 12 - | Hexagon bolt |

| q | M14 x 1.5 x 95 |

| q | 150 Nm and turn 90° further. |

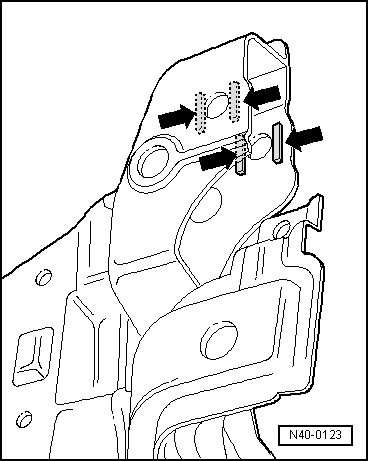

| q | Check rear bonded rubber bush is correctly positioned in the subframe before tightening → Fig.. |

| q | Renew each time after removing. |

| 13 - | Allen head bolt, 55 Nm |

| 14 - | Swivel joint |

| q | Removing and installing → Chapter. |

| 15 - | Nut |

| q | 30 Nm and turn 90° further. |

| q | Self-locking |

| q | Renew each time after removing. |

| q | Brace with 7 mm Allen key while fitting the nut. |

| 16 - | Suspension link |

| q | Installation position in subframe → Fig. |

| q | Removing and installing → Chapter. |

| 17 - | Hexagon bolt |

| q | M14 x 1.5 x 90 |

| q | 90 Nm and turn 90° further. |

| q | Renew each time after removing. |

| 18 - | Front wishbone mounting |

| q | Pressing out → Fig.. |

| q | Pressing in → Fig.. |

| 19 - | Hexagon bolt |

| q | 60 Nm and turn 90° further |

| q | Always renew after removing |

| If the pendulum support, item → Item, is made of aluminium, the specified torque is 70 Nm. |

| Modifications to the screw → Chapter. |

| 20 - | Rubber bush |

| 21 - | Pendulum support |

| At the start of production, supports with two and three holes for subframe mounting were produced. |

| After a short startup phase, these were replaced by a support with one hole. |

| Only the support with one hole will be supplied as a replacement part. |

| If this support is installed in a vehicle which was previously fitted with a different support, two spacers must be attached, each 2.5 mm thick. |

| Other modifications to the pendulum support → Chapter. |

| 22 - | Hexagon nut |

| q | Renew each time after removing. |

| 23 - | Hexagon bolt |

| q | 100 Nm |

| q | Always renew after removing |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|