| The wheel bearings must not be loaded while a hexagon bolt is loose. |

| If wheel bearings are loaded with weight of vehicle, bearing will be damaged. This reduces the service life of the wheel bearing. |

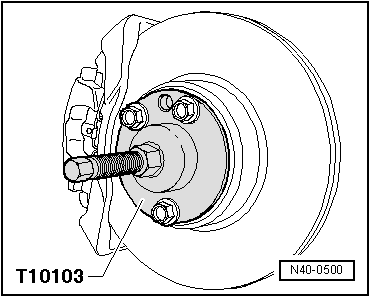

| If a vehicle has to be moved after removing the drive shaft, first install outer joint and tighten to 50 Nm otherwise the wheel bearing will be damaged. |

| –

| Thoroughly clean gearbox around the inner joint. |

| –

| Lift vehicle until the load on the front axle is relieved. |

| –

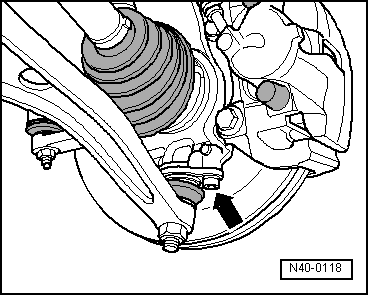

| Remove hexagon bolt for drive shaft. |

| –

| Remove wheel and raise vehicle. |

| –

| Remove noise insulation tray. |

|

|

|