| t

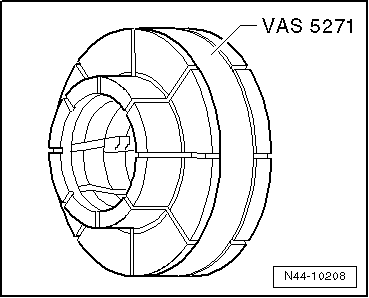

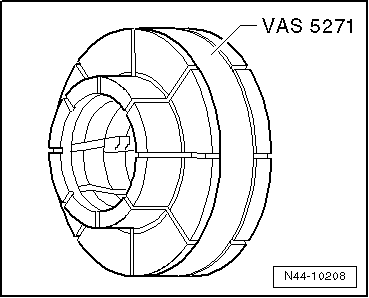

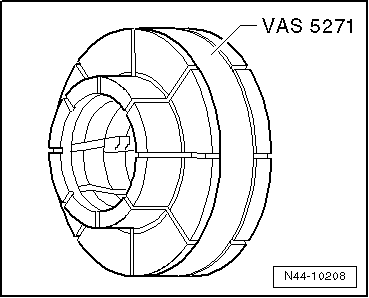

| To clamp the wheel, use e.g. centring system for wheel balancing machines -VAS 5271-. |

| t

| This ensures that the wheel is 100% centred and that the wheel will be clamped without damage! |

| t

| The wheel cannot be centralised 100% with conical clamping elements on the wheel balancing machine. |

| t

| A deviation of 0.1 mm from the centre results in an imbalance of 10 grams at the wheel/rim. |

| Procedure for balancing wheels and tyres |

| –

| Rotate wheel and tyre on wheel balancer. |

| –

| Check that the indicator lines on the sidewall of the tyre near the wheel rim flange run evenly. |

| –

| Check that the body of the tyre runs evenly while the wheel and tyre are rotating. |

Note | If one-sided wear, flat spots from braking or severely washed out spots are apparent, balancing cannot achieve smooth running. In this case, the tyre must be renewed. |

| –

| Check the true running of the wheel and tyre. If the wheel and tyre do not run true although there are no flat spots, radial or lateral runout may be the cause. |

| –

| Check the wheel for radial or lateral runout → Chapter. |

| –

| If radial and lateral runout are within the specified tolerance, balance the wheel and tyre. |

Note | t

| More than 60 grams of weight per tyre should not be used. |

| t

| If more weight is required, you may be able to achieve smoother running by "matching" the tyre and rim. Matching tyres → Chapter. |

| t

| The wheel balancer display should indicate 0 gram. |

| t

| As an alternative to match mounting, you could use the vibration control system -VAS 6230- → Chapter. |

| –

| Bolt the wheel to the vehicle. |

| –

| First hand-tighten the lowest wheel bolt to about 30 Nm. |

| –

| Then tighten the remaining wheel bolts diagonally to about 30 Nm. This process centres the wheel on the hub. |

| –

| Lower vehicle onto its wheels. |

| –

| Now use a torque wrench to tighten the wheel bolts diagonally to the specified torque. |

| –

| After balancing the wheels and tyres, carry out a road test. |

| If you detect vibration during the road test, it may be due to tolerance in the wheel centring. |

| In unfavourable circumstances, the component tolerances of wheels and hubs could cumulate. This too can lead to vibration. This can be alleviated using a finish balancer. → Chapter |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note