Leon Mk1

Note

Note

|

|

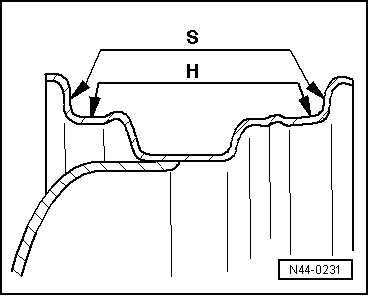

| Specifications for radial and lateral runout on wheel |

| Wheel | Radial runout (mm) | Lateral runout (mm) | |

| Steel wheel | 0.5 | 0.5 | |

| Alloy wheel | 0.5 | 0.8 | |

Note

Note| If the measured value exceeds the specification, acceptably smooth running cannot be attained. |