| –

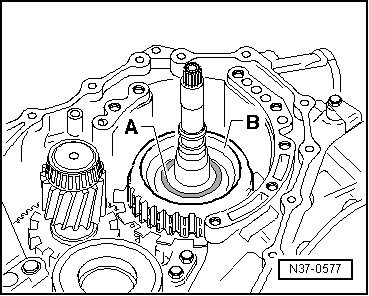

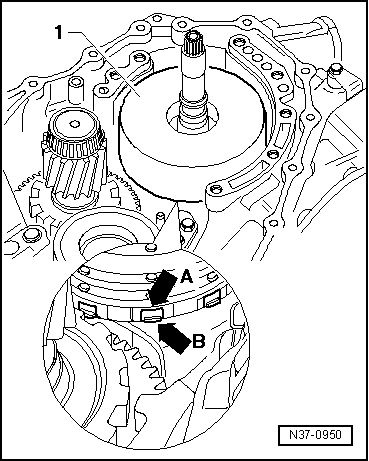

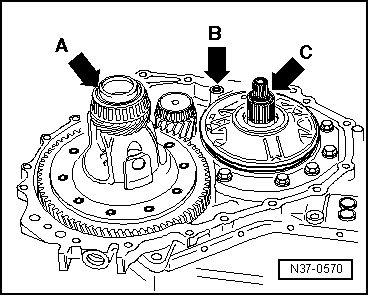

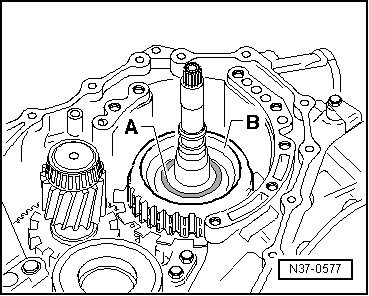

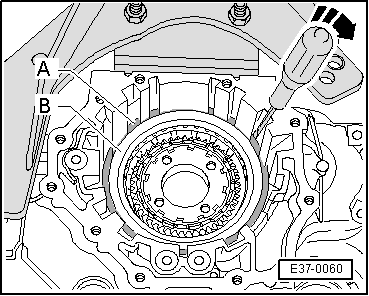

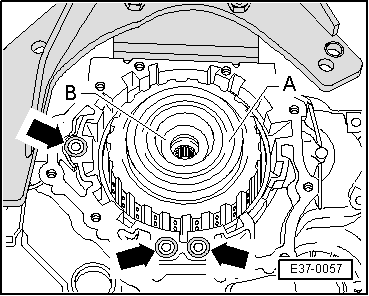

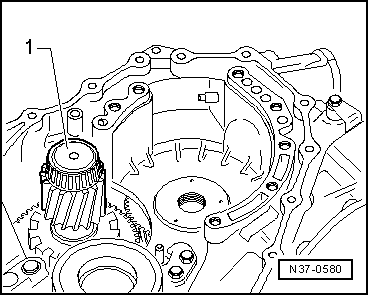

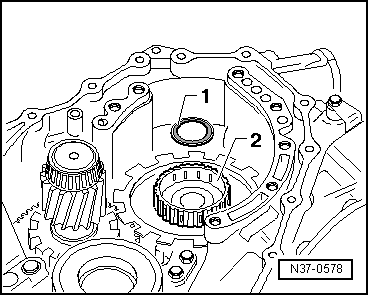

| Insert the clutch for the 1st and 3rd gear -B-. |

Note! | When inserted, the input shaft must completely enter the clutch for the 1st and 3rd gear. If necessary, fit them together before inserting them into the casing. |

| –

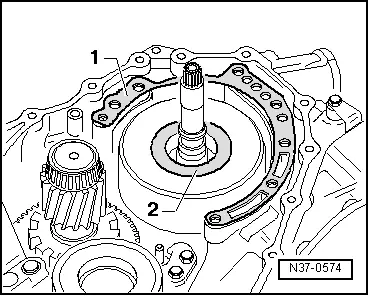

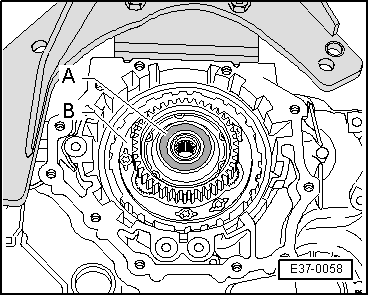

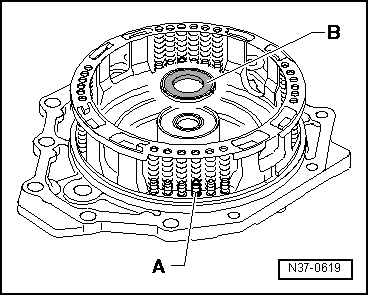

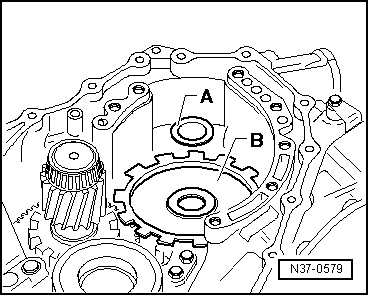

| Place the axial needle bearing -A- on the clutch for the 1st and 3rd gear in accordance with the correct installation position (the dark surface remains visible). |

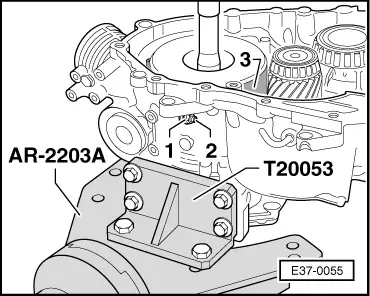

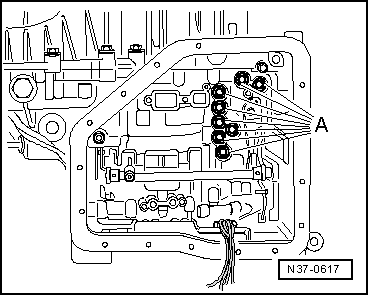

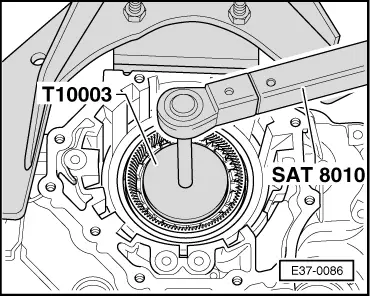

| When replacing individual components of the planet gears, the axial needle bearings must be calibrated anew → Chapter, Adjust the clearance for the clutch. |

|

|

|

Note!

Note!