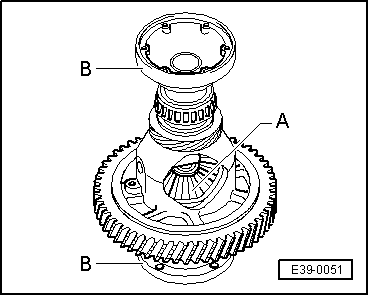

| Fitting sun gear and planetary gears |

| –

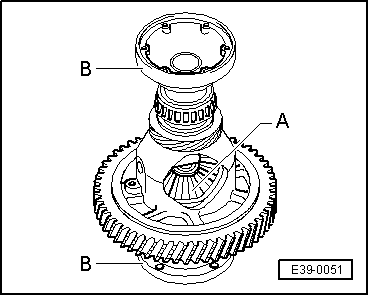

| Coat the thrust washers with gearbox oil and fit in the differential casing. |

| –

| Fit the sun gears -A- and secure with flange shafts -B-. |

| –

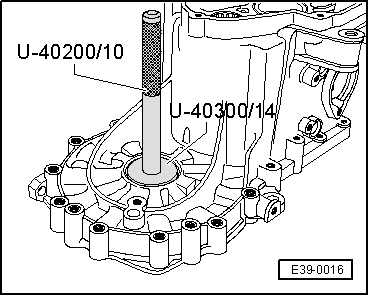

| Insert one planet gear and turn 180. |

| –

| Fit the second satellite in the opposite position to the first. |

| –

| In this position, turn the planetary gear towards the inside of the differential casing using flanged shafts, until they coincide with the holes on the planetary gear shaft. |

| –

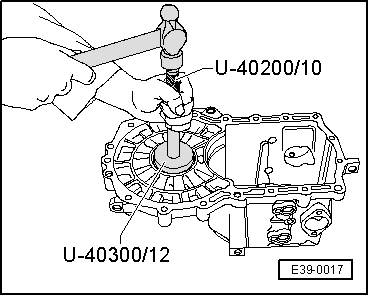

| Insert the satellite shaft until it moves the first satellite. |

| –

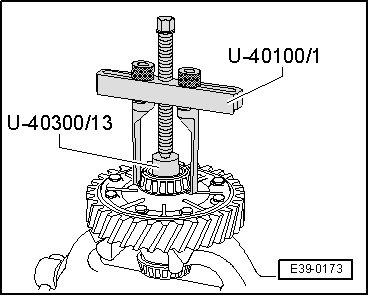

| Fit the threaded units for securing articulation flanges, ensuring that they are properly seated. |

| –

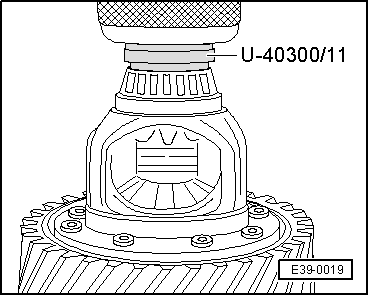

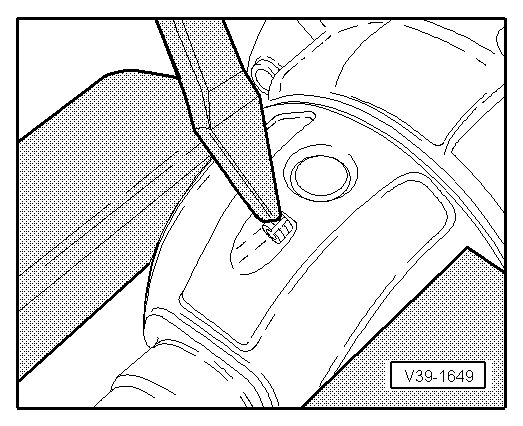

| Fit the satellite shaft into its final position and install a new elastic pin to secure it. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note