| Adjust the sliding sleeve and the prong for the 5th gear |

| –

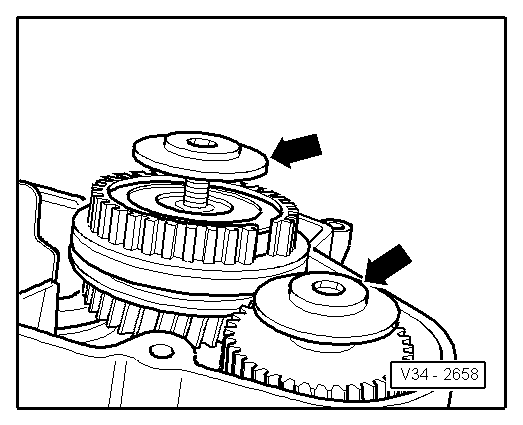

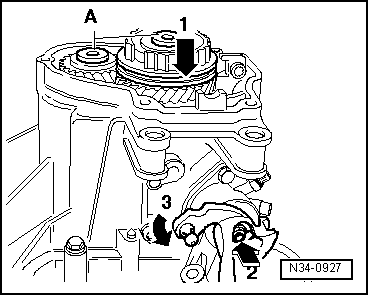

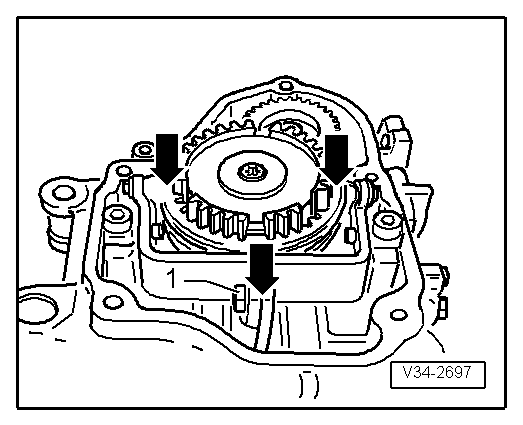

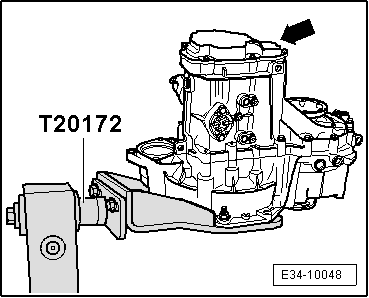

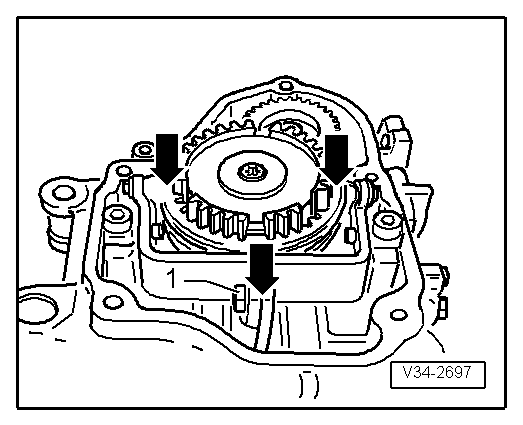

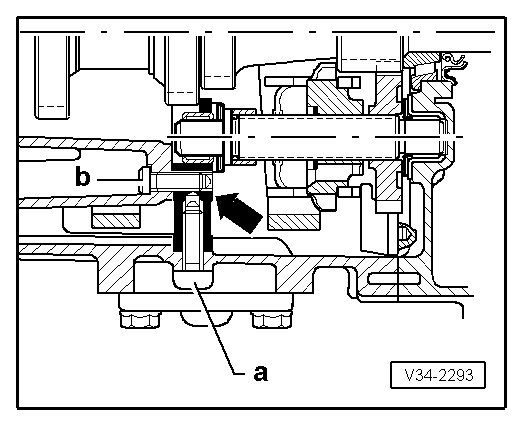

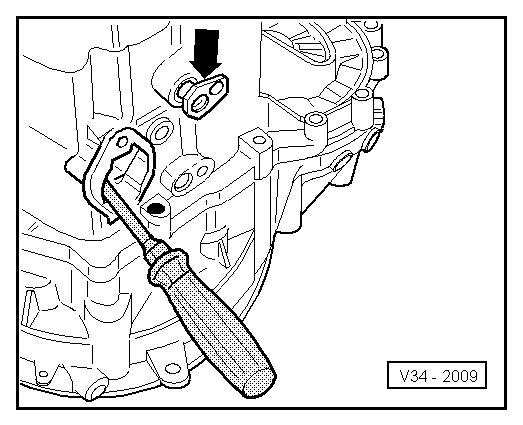

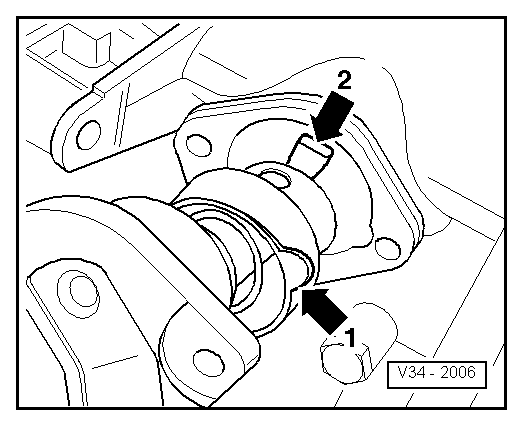

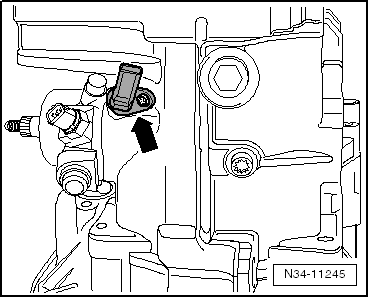

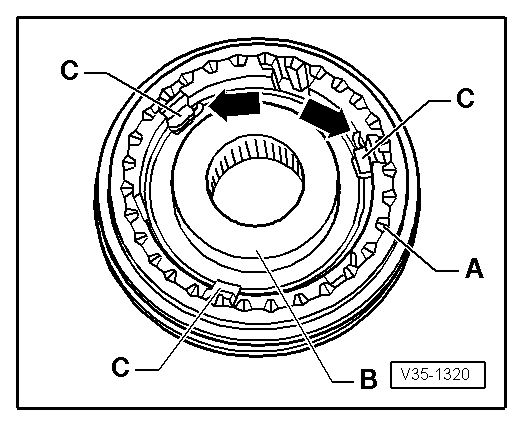

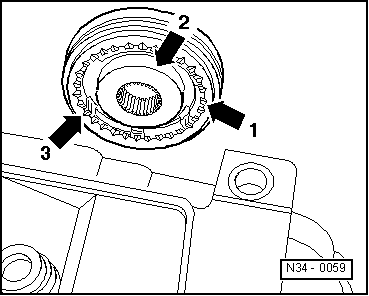

| 5. Gear engaged. Loosen bolt -1-. Press the mobile sleeve and the gear mouth in the direction of the -arrow-; then tighten the bolt -1- to 25 Nm. |

| l

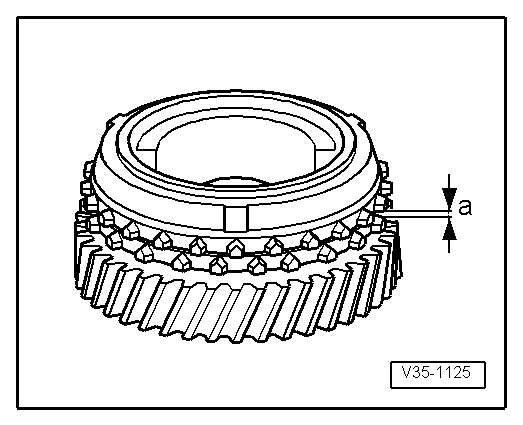

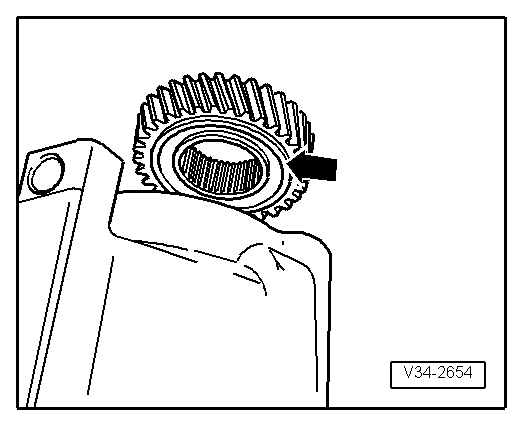

| Control measurement: Between the mobile sleeve and the mobile pinion, a thickness gauge of 0.2 mm cannot be inserted. If necessary, repeat the adjustment process. |

| –

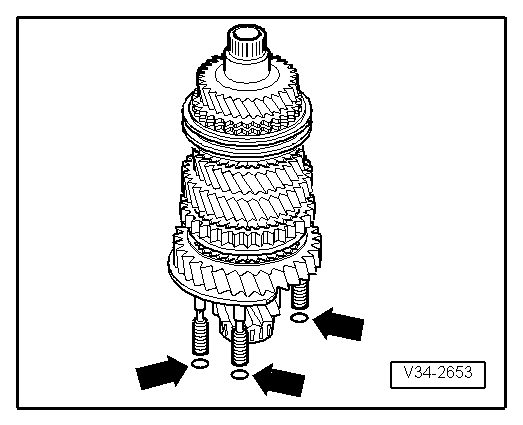

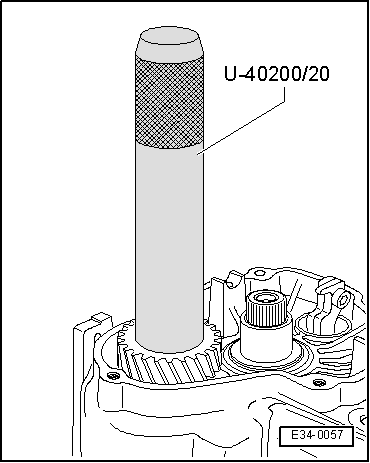

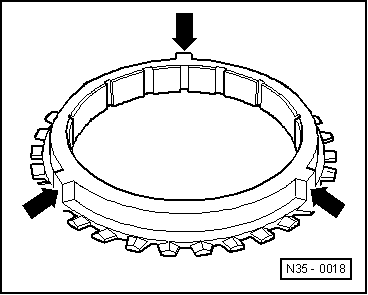

| Shift out of 5th gear. The sleeve must be situated in neutral position and the synchrony ring must turn freely in this position. |

| –

| Shift through all gears. |

|

|

|

Note

Note Note

Note

Note

Note