Leon Mk2

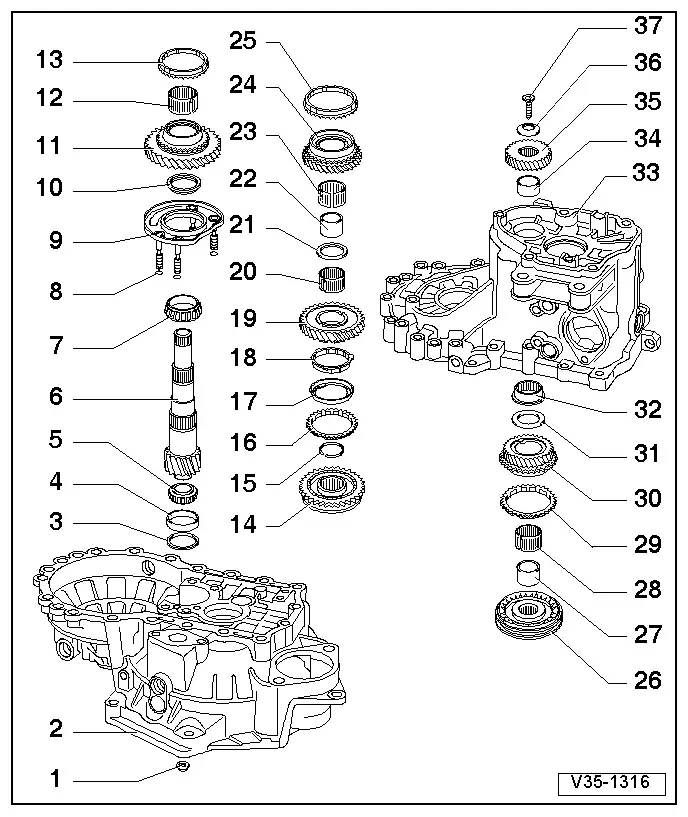

| Secondary shaft: assembly overview |

Note

Note| t | When installing new gears or a output shaft, see technical data → Chapter, Identification letters, group allocation, ratios, filling quantities |

| t | If the layshaft or roller bearings are replaced, the layshaft must be adjusted → Chapter |

| t | The layshaft must be adjusted whenever elements have been replaced which could affect the position of the roller bearings. Refer to Adjustment chart → Chapter |

| 1 - | Conical hexagon bolt |

| q | 25 Nm + 90° |

| q | 4x |

| q | To secure the bearing housing |

| 2 - | clutch housing |

| q | Repairing → Chapter |

| 3 - | Shim |

| q | For secondary shaft |

| q | Determining thickness → Chapter |

| 4 - | Small tapered roller bearing outer race |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 5 - | Small roller bearing |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 6 - | Output shaft |

| q | Paired with final drive gear wheel. Always renew as a set. |

| q | In case of replacement → Chapter, Code letters, group allocation, ratios, capacities |

| q | Adjusting → Chapter |

| 7 - | Large roller bearing |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 8 - | Sealing ring |

| q | 4x |

| q | Always replace |

| q | For the securing bolts of the bearing housing → Item |

| 9 - | Bearing housing |

| q | With large primary shaft bearing outer track → Item |

| q | The external track should only be replaced together with the large roller bearing and the bearing housing |

| 10 - | Thrust washer |

| q | Shoulder of thrust washer faces tapered roller bearing |

| 11 - | 1st speed selector gear |

| q | Before fitting the gear pinion of the 1st gear, install the thrust washer → Item |

| 12 - | Needle bearing |

| q | for the 1st gear mobile pinion |

| 13 - | Synchro-ring for 1st gear |

| q | Identification → Fig. |

| q | Checking for wear → Fig. |

| q | Check that the tabs show no signs of wear |

| 14 - | Synchronising hub for 1st and 2nd gear |

| q | Removing → Fig. |

| q | Dismantling → Fig. |

| q | Assembly of components → Fig. and → Fig. |

| q | Installation position → Fig. |

| q | Installing → Fig. |

| 15 - | Circlip |

| q | Use pliers -A 81124- to remove the safety ring. |

| q | Always replace |

| 16 - | Outer synchroniser ring for 2nd gear |

| q | Identification → Fig. |

| q | Checking for wear → Fig. |

| q | Fitting position: the grooves in the synchromesh ring must fit with the pins in the synchromesh assembly of 1st and 2nd gear → Item |

| 17 - | Middle synchroniser ring for 2nd gear |

| q | Fit into the outer synchromesh ring of the 2nd gear → Item |

| q | Installation position → Fig. |

| q | Replace if it shows signs of wear or grooves |

| 18 - | Inner synchroniser ring for 2nd gear |

| q | Identification → Fig. |

| q | Checking for wear → Fig. |

| q | Check that the tabs show no signs of wear |

| q | Installation position → Fig. |

| 19 - | 2nd speed selector gear |

| q | Installation position → Fig. |

| 20 - | Needle bearing |

| q | For 2nd gear mobile pinion |

| 21 - | Thrust washer |

| 22 - | Needle bearing bush |

| q | Remove together with the mobile pinion of 2nd gear → Fig. |

| q | Installing → Fig. |

| 23 - | Needle bearing |

| q | For the 3rd gear selector gear |

| 24 - | 3rd speed selector gear |

| 25 - | Synchromesh ring 3rd gear |

| q | Identification → Fig. |

| q | Checking for wear → Fig. |

| 26 - | Synchromesh body of 3rd and 4th gear |

| q | Removing → Fig. |

| q | Dismantling → Fig. |

| q | Assemble → Fig. and → Fig. |

| q | Installation position → Fig. |

| q | Installing → Fig. |

| 27 - | Needle bearing bush |

| q | Remove together with the synchromesh assembly of the 3rd and 4th gear → Item |

| q | Installing → Fig. |

| 28 - | Needle bearing |

| q | For 4th gear mobile pinion |

| 29 - | Synchroniser ring for 4th gear |

| q | Identification → Fig. |

| q | Checking for wear → Fig. |

| 30 - | 4th speed selector gear |

| 31 - | Thrust washer |

| 32 - | Needle bearing |

| q | For secondary shaft |

| q | Removing and fitting → Chapter, Gearbox housing and clutch housing: repairs |

| 33 - | Gearbox |

| 34 - | Needle bearing bush |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 35 - | 5th gear mobile pinion |

| q | Installation → Chapter, Gearbox housing cover and 5th gear: Removing and installing |

| 36 - | Dished washer |

| q | Fitting position: The concave side should be facing the selector gear for the 5th gear |

| 37 - | Attachment bolt of 5th gear mobile pinion |

| q | The screw head incorporates a housing for the plate spring → Item |

| q | Fitting → Chapter, Gearbox housing cover and 5th gear: Removing and installing |