Leon Mk2

Note

Note

|

|

|

|

|

|

|

Note

Note

|

|

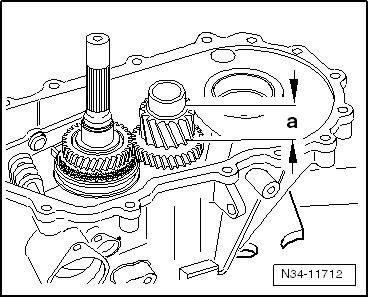

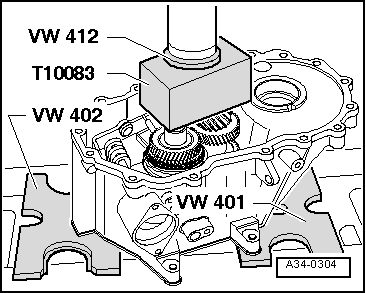

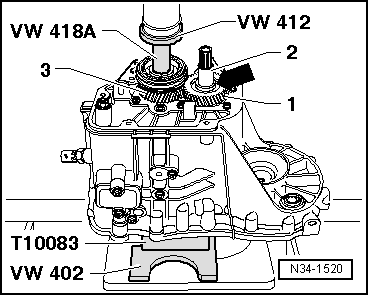

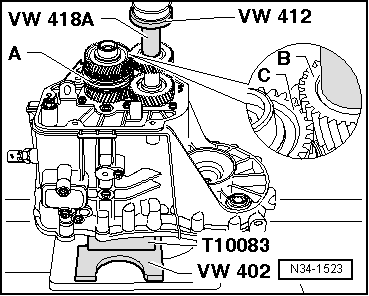

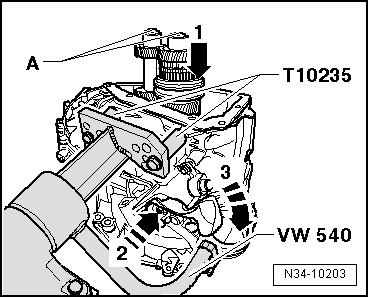

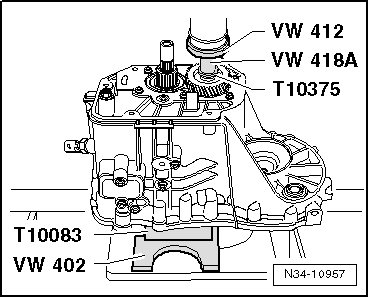

| Dimension -a- = 30.6 mm | |

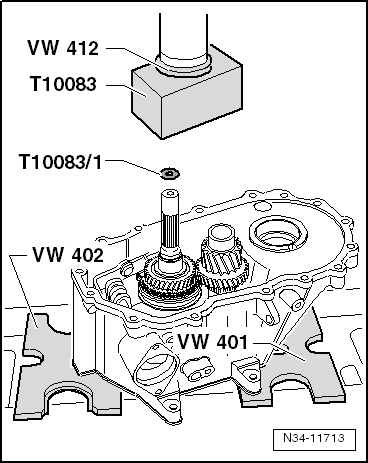

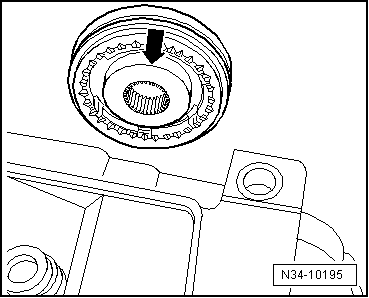

| Place shim -T10083/1- onto input shaft ⇒ next figure. |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING