Leon Mk2

|

Note

Note

|

|

|

|

Note

Note

Note

Note |

|

|

|

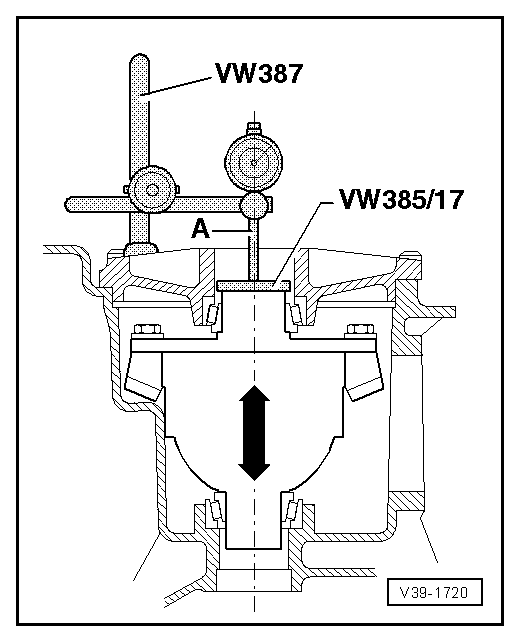

| Example: | ||

| Inserted shim(s) „S2*“ | 1.30 mm | |

| + | Average value | 0.62 mm |

| + | Bearing preload (constant value) | 0.25 mm |

| = | Total shim thickness „Stot“ for „S1“ plus „S2“ | 2.17 mm |

Note

Note

|

| Example: | ||

| Total shim thickness „Stot“ for „S1“ plus „S2“ | 2.17 mm | |

| - | Inserted shim(s) „S2*“ | 1.30 mm |

| = | Thickness of shim „S1*“ | 0.87 mm |

|