Leon Mk2

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

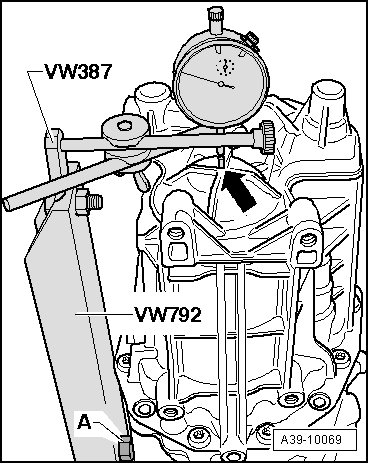

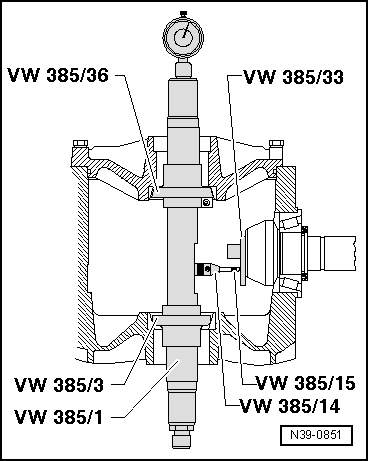

| Example: | ||

| Inserted shim „S4*“ | 1.01 mm | |

| + | Measured value (example) | 0.46 mm |

| + | Bearing preload (constant value) | 0.12 mm |

| = | Total shim thickness „Stot“ for „S3“ plus „S4“ | 1.59 mm |

|

| Example: | ||

| Total shim thickness „Stot“ for „S3“ plus „S4“ | 1.59 mm | |

| - | Inserted shim „S4*“ | 1.01 mm |

| = | Thickness of shim „S3*“ | 0.58 mm |

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|