| –

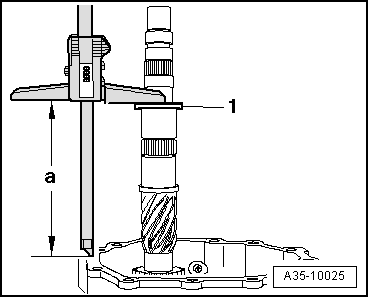

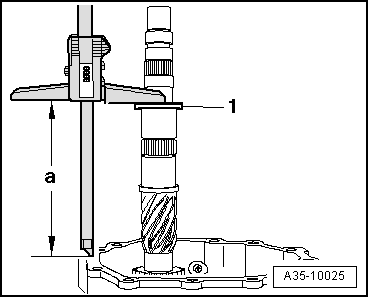

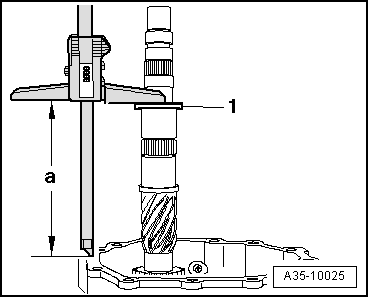

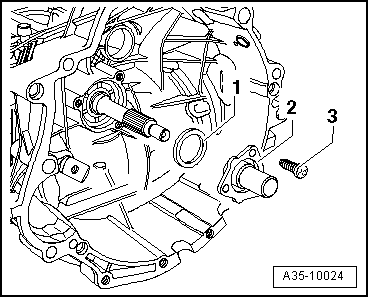

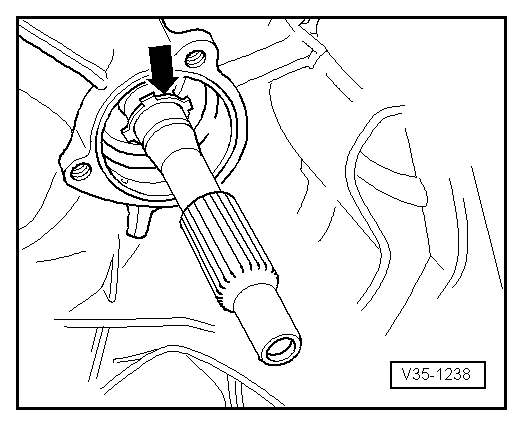

| Place thrust washer -1- for 4th and 5th speed selector gears onto input shaft. |

| –

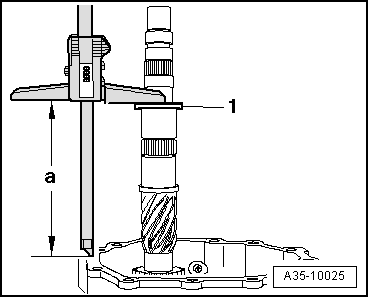

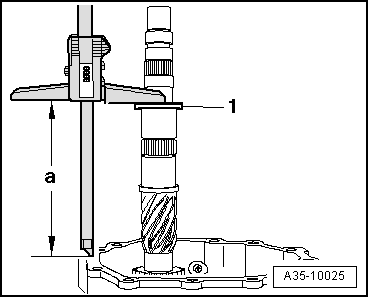

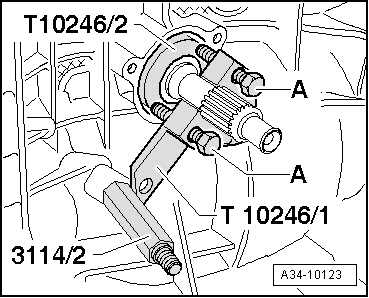

| Place a digital depth gauge (e. g. -VAS 6087-) onto the thrust washer and measure the distance to the contact surface of the housing. The measuring point on the housing contact surface must be as close to the input shaft as possible. |

Note | When measuring, lift the input shaft with e.g. support bridge - 30-211A- or the help of a second mechanic until the play in the ball bearing is taken up. |

| Specification for dimension „a“: 164.14 mm |

Note | t

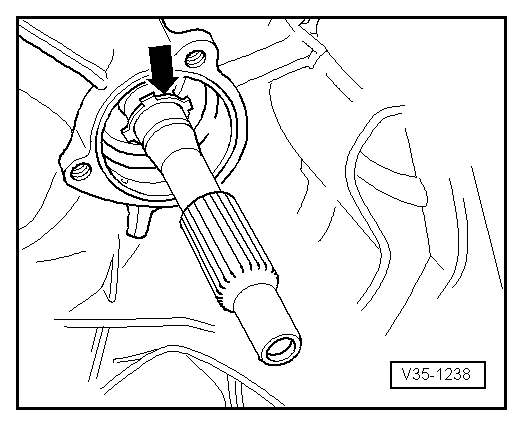

| If the measured value exceeds the specification, use a thinner circlip than the circlip installed so that the specification is attained. |

| t

| If the measured value is below the specification, use a thicker circlip than the circlip installed so that the specification is attained. |

| t

| Determine the circlip thickness to meet the specification as exactly as possible (164.14 mm). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note