| Gearbox for all-wheel drive in conjunction with turbo diesel engine |

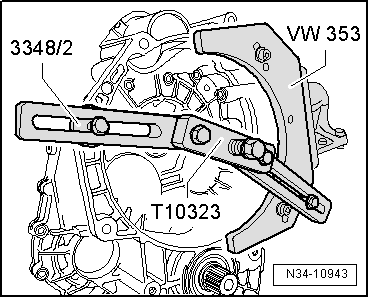

| Mount bevel box on manual gearbox outside vehicle. |

| –

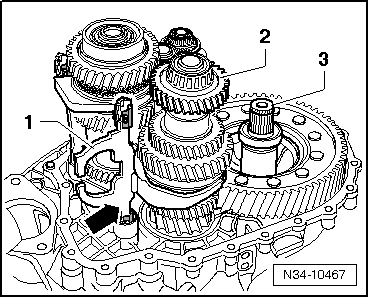

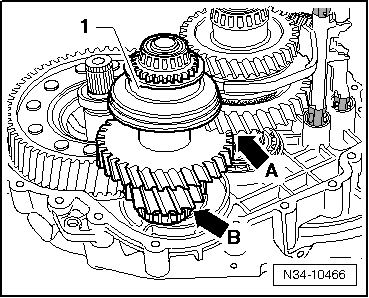

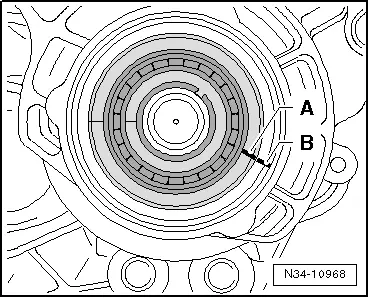

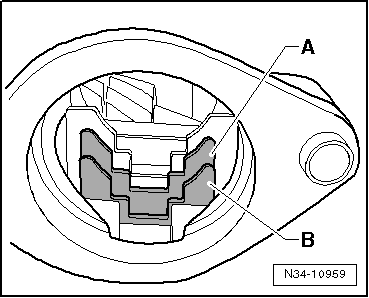

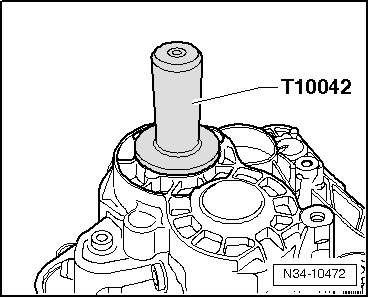

| Grease splines of differential with grease for clutch plate splines -G 000 100-. |

| –

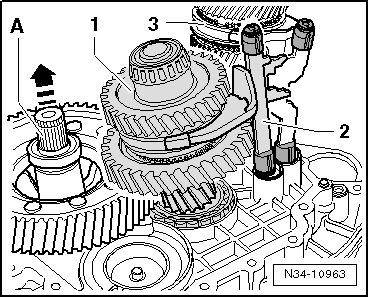

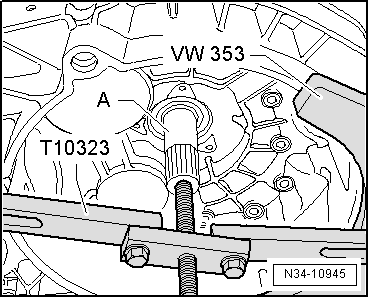

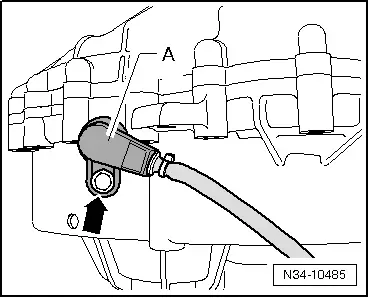

| Push bevel box completely onto gearbox, ensuring that splines of bevel box input shaft and differential are centred when brought together. |

| –

| Align splines of right stub shaft and differential bevel gear, turning stub shaft if necessary. |

| –

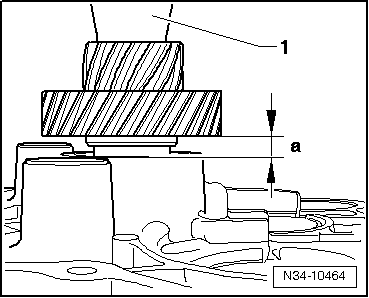

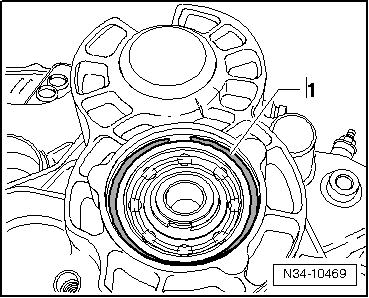

| If splines are correctly positioned and shafts are centred, then bevel box will slide to stop against gearbox. |

Note | Do not use securing bolts to pull bevel box onto gearbox, or bevel box will cant and bolt holes can break off. |

| –

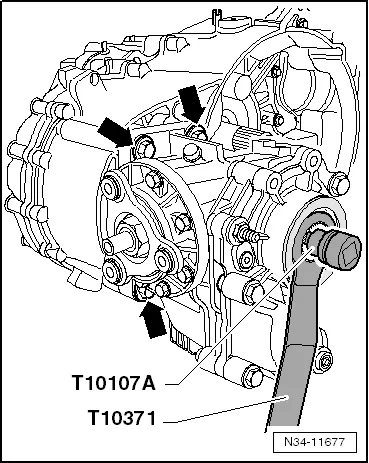

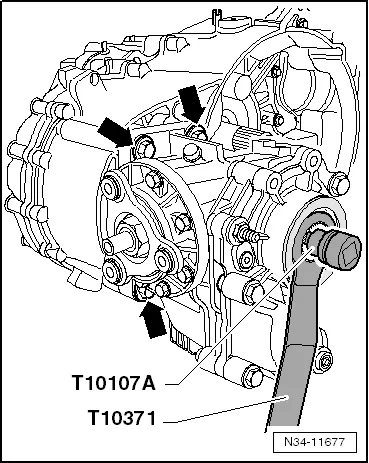

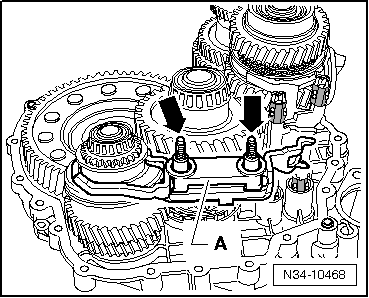

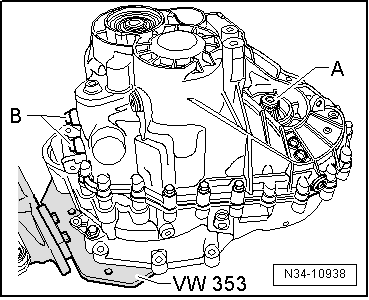

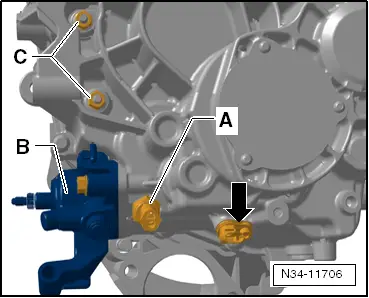

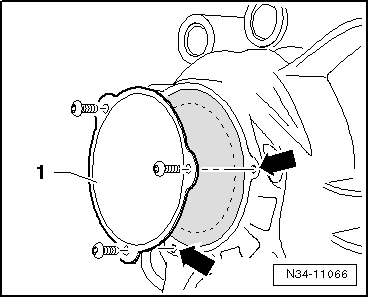

| Tighten the 4 connecting bolts -arrows- for bevel box to gearbox with specified torque (only 3 are visible in figure) → Item. |

| –

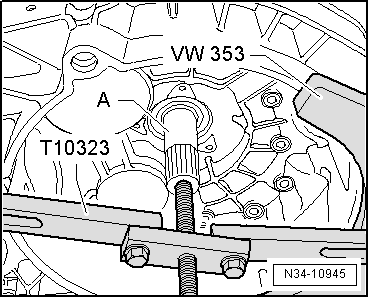

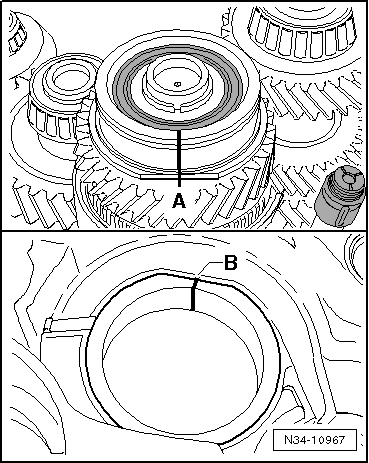

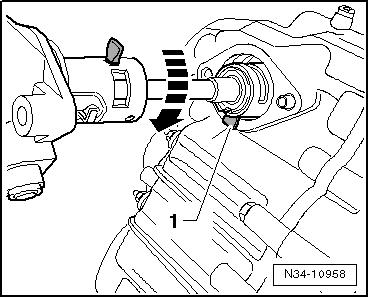

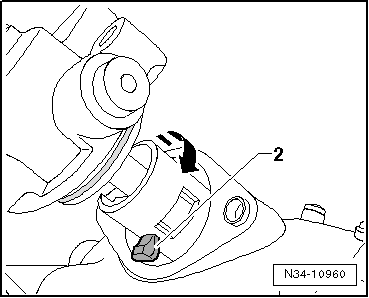

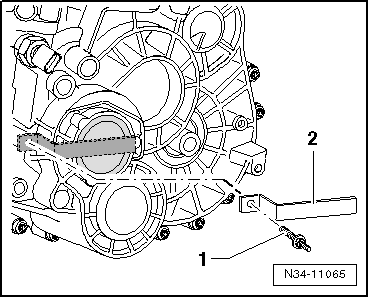

| Tighten the countersunk bolt for the stub shaft on the right using the hexagon socket -T10107A- to the corresponding tightening torque → Item. |

|

|

|

Note

Note

Note

Note

Note

Note