Leon Mk2

| Dismantling and assembling output shaft for 1st and 2nd gear |

| Special tools and workshop equipment required |

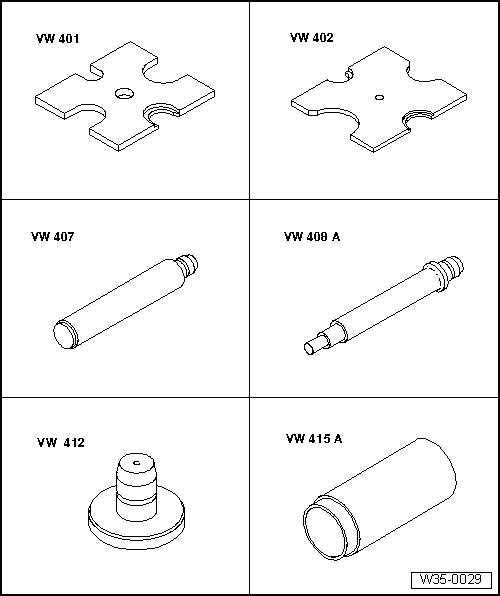

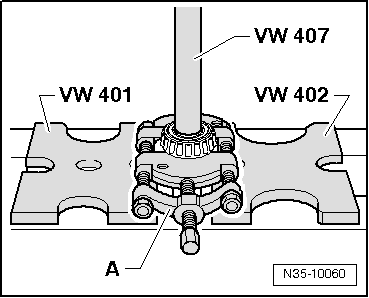

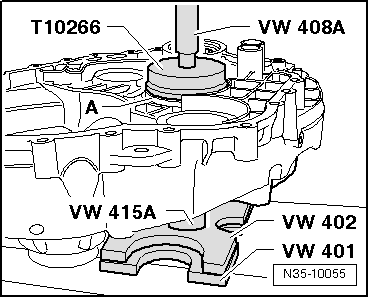

| t | Pressure plate -VW 401- |

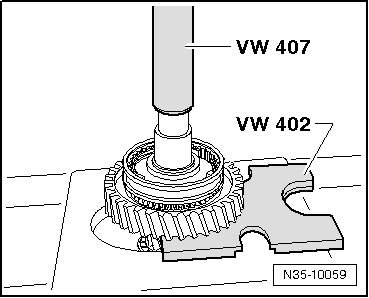

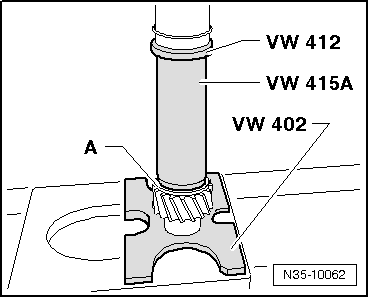

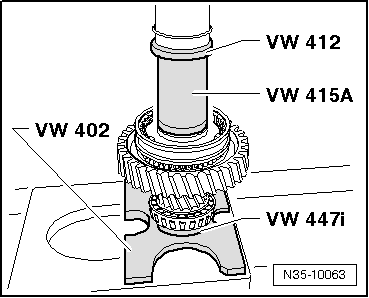

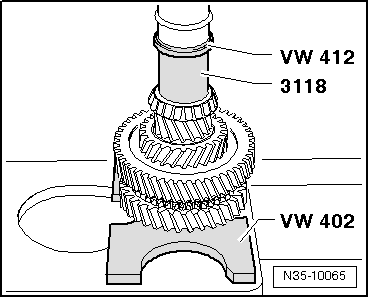

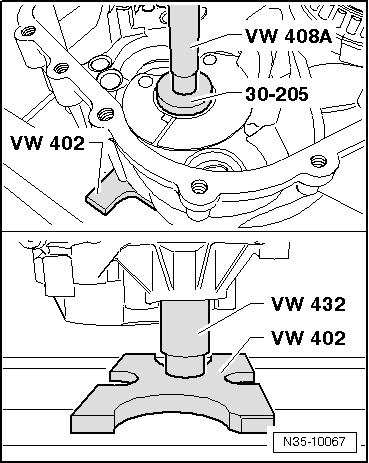

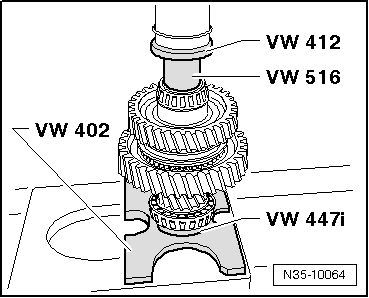

| t | Pressure plate -VW 402- |

| t | Press die. -VW 407- |

| t | Press die. -VW 408 A- |

| t | Press die. -VW 412- |

| t | Tube -VW 415 A- |

| t | Thrust piece -VW 431- |

| t | Thrust piece -VW 432- |

| t | Thrust pad -VW 447 i- |

| t | Tube -VW 516- |

| t | Tightening plate -30 - 205- |

| t | Tightening plate -40 - 105- |

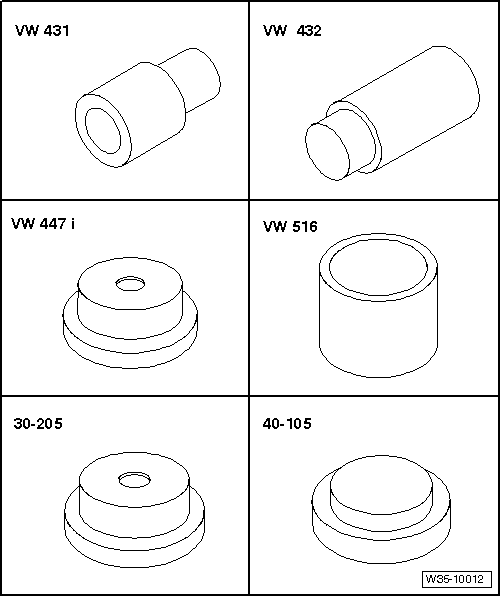

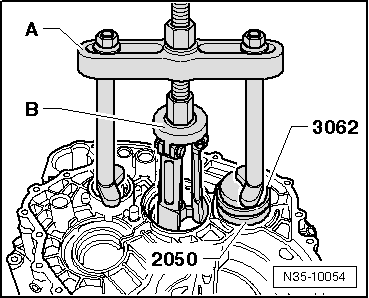

| t | Thrust piece -2050- |

| t | Thrust pad -3062- |

| t | Thrust piece -3118- |

| t | Thrust piece -3401- |

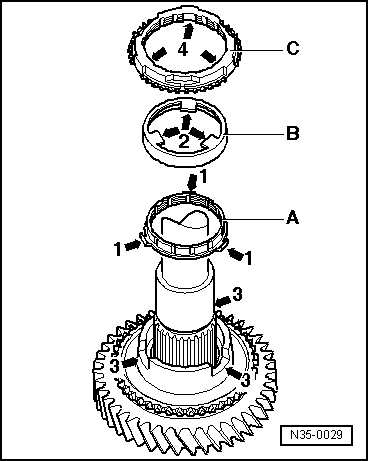

| t | -1-Internal puller 14.5...18.5 mm, e.g. -Kukko 21/2- |

| t | -1-Internal puller 46...58 mm, e.g. -Kukko 21/7- |

| t | -1-Internal puller 56...110 mm, e.g. -Kukko 21/89- |

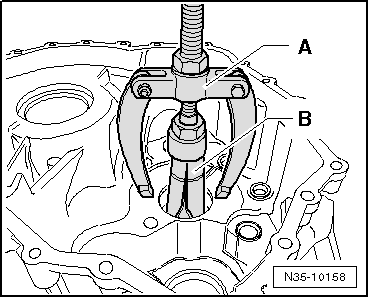

| t | -3-Splitter, 22 ... 115 mm, e.g. -Kukko 17/2- |

| t | -4-Counter support , e.g. -Kukko 22/1- |

| t | -4-Counter support , e.g. -Kukko 22/2- |

| t | -4-Counter support , e.g. -Kukko 22/4- |

| t | -1-Two arm puller, e.g. -Kukko 20/10- |

| t | Feeler gauge |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

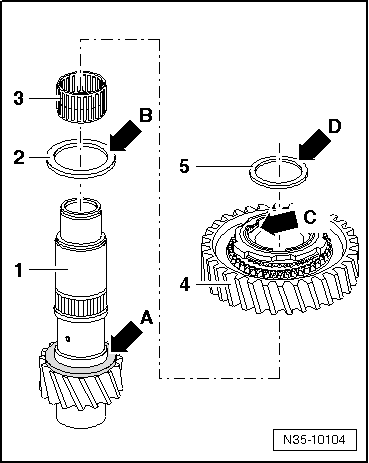

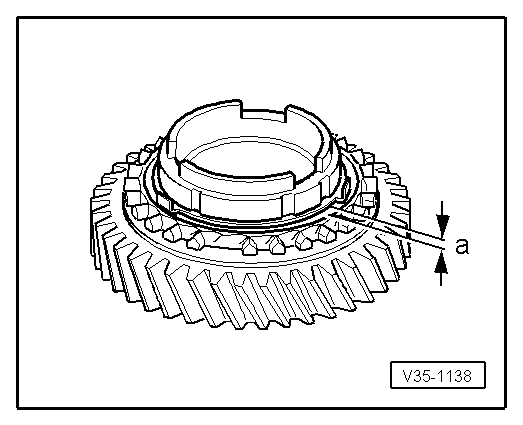

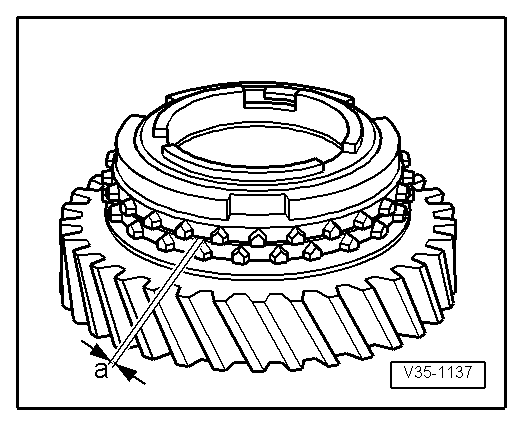

| Dimension -a- | Installation dimension | Wear limit |

| 1. and 2nd gear | 0.75 … 1.25 mm | 0.3 mm |

|

|

| Dimension -a- | Installation dimension | Wear limit |

| 1. and 2nd gear | 1.0 … 1.8 mm | 0.5 mm |

|

|

|

|

|

|

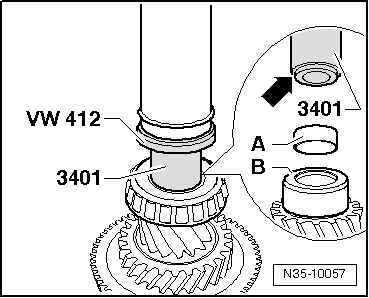

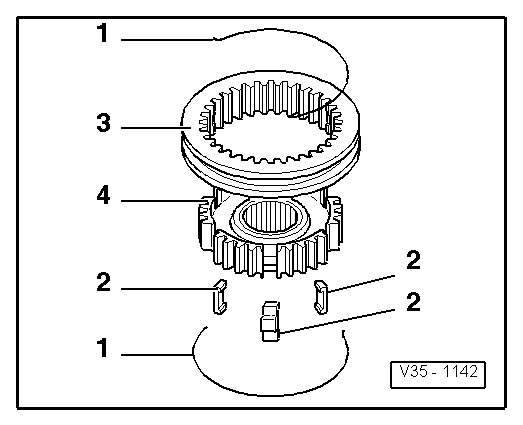

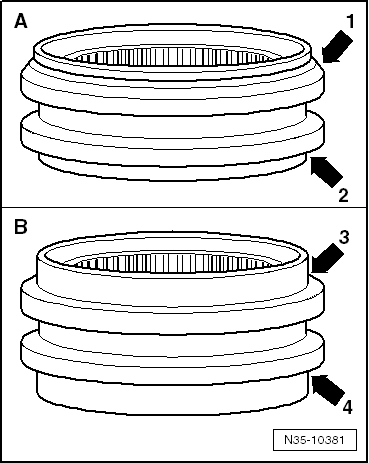

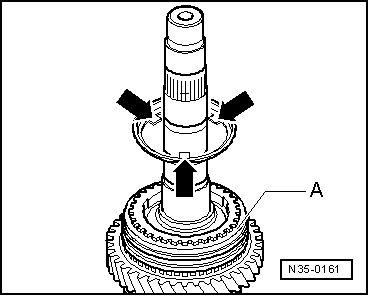

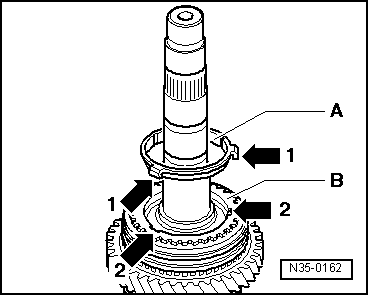

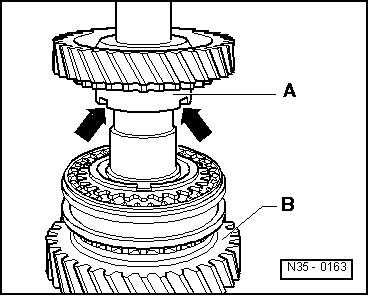

| -A- | ||

| Chamfer -arrow 1- faces lower shoulder of synchro-hub. | ||

| Shoulder -arrow 2- faces higher shoulder of synchro-hub. |

| -B- | ||

| Shoulder -arrow 3- and shoulder -arrow 4- are the same size = no installation position. |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|