Leon Mk2

|

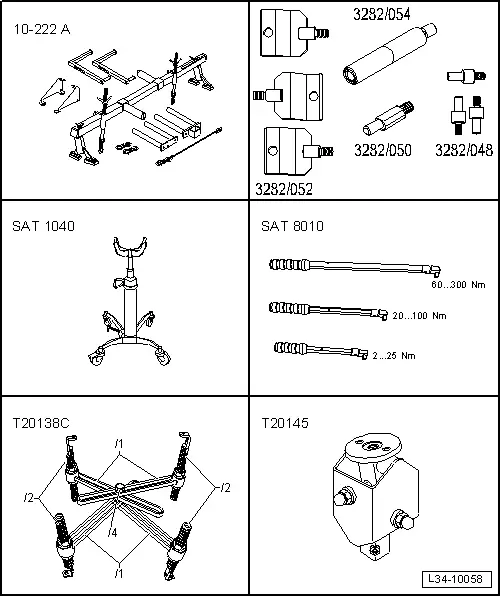

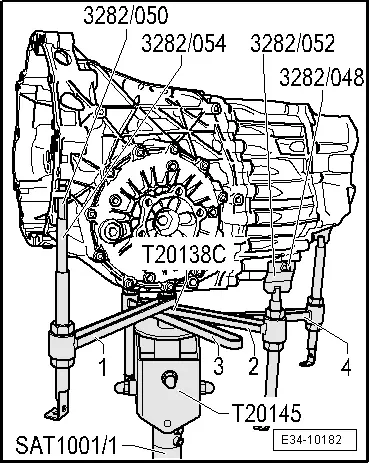

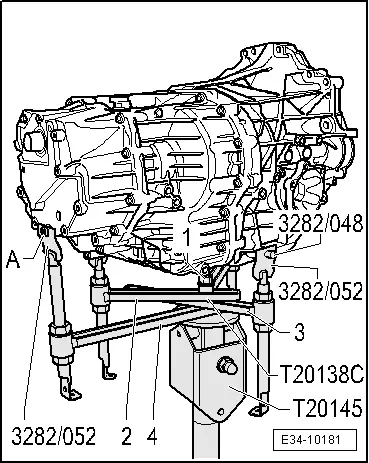

| Special tools and workshop equipment required |

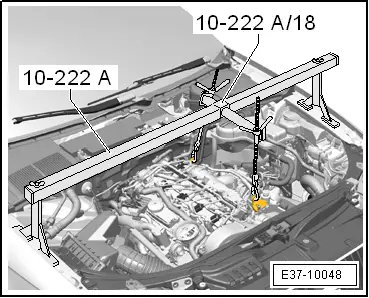

| t | Support bracket -10-222 A- |

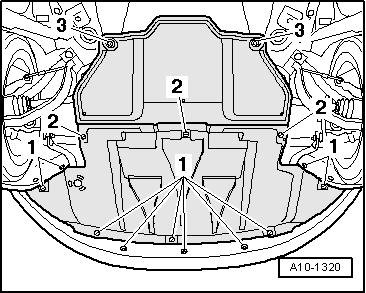

| t | Adjustment plate -3282/052-, adjustment plate -3282/048-, extension -3282/050- and extension -3282/054- |

| t | Hydraulic jack -SAT 1040-, see equivalent → Anchor |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

| t | Gearbox support -T20138C-, see equivalent → Anchor |

| t | Base -T20145- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution