Leon Mk2

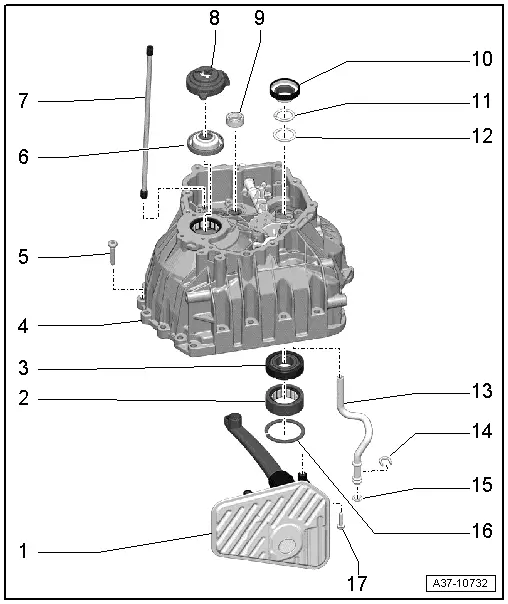

| Part 1 |

| 1 - | ATF strainer |

| q | Different versions |

| q | Removing and installing → Chapter>>>>>>>> |

| 2 - | Bearing „D“ |

| q | Roller bearing for pulley set „I“ |

| q | Different procedures: with or without inner race |

| q | Removing and installing → Chapter>>>>>>>> |

| 3 - | Bearing „E“ |

| q | Ball bearing for pulley set „I“ |

| q | Removing and installing → Chapter>>>>>>>> |

| 4 - | Intermediate housing |

| q | Removing and installing → Chapter>>>>>>>> |

| 5 - | Bolt. |

| q | Different types and lengths according to version |

| q | Renew bolts |

| q | Steel bolt, 25 Nm |

| q | Aluminium bolt, 10 Nm + tighten 90° (1/4 turn) further |

| 6 - | Sender wheel „II“ |

| q | Always renew after removal |

| q | Removing and installing → Chapter>>>>>>>> |

| 7 - | Oil pipe |

| q | Take care not to damage sealing surfaces |

| q | Removing and installing → Chapter>>>>>>>> |

| 8 - | Cover |

| q | For sender wheel „II“ |

| 9 - | Axial sealing element |

| q | For ATF filter |

| q | replace |

| 10 - | Sender wheel „I“ |

| q | Always renew after removal |

| q | Removing and installing → Chapter>>>>>>>> |

| 11 - | Circlip |

| q | replace |

| q | A new dimension must be set again after replacing the pulley set „I “ → Anchor |

| q | Must be properly seated in the base of the groove |

| q | Fitting position: The boreholes in the eyes are tapered. The smaller side faces upwards |

| 12 - | Shim |

| q | A new dimension must be set again after replacing the pulley set „I “ → Anchor |

| 13 - | Oil pipe |

| 14 - | Retainer tab |

| q | For oil pipes |

| 15 - | O ring |

| q | replace |

| 16 - | Circlip |

| q | For ball bearing and roller bearing |

| 17 - | Bolt. |

| q | 10 Nm |

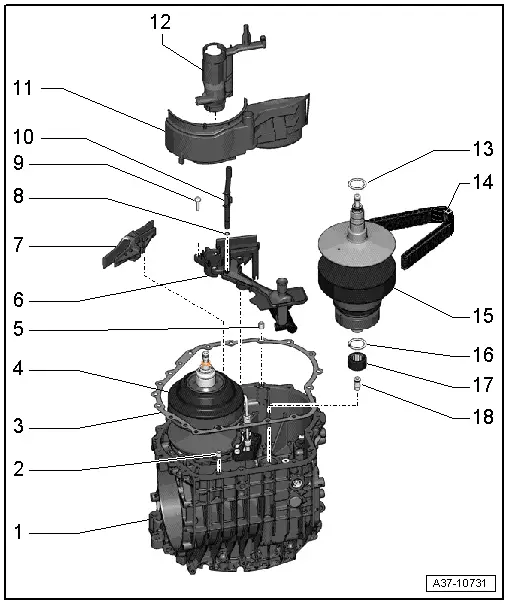

| Part 2 |

| 1 - | Gearbox |

| q | With pulley set „II“ |

| 2 - | Dowel sleeve |

| 3 - | Seal |

| q | replace |

| 4 - | Pulley set „II“ |

| q | Cannot be renewed separately |

| 5 - | Dowel sleeve |

| 6 - | Suction-jet pump |

| q | Removing and installing → Chapter>>>>>>>> |

| 7 - | Guide rail |

| q | Fixed with clamps on the oil pipe -item 10- |

| q | Install with chain mounted |

| 8 - | O ring |

| q | For oil pipes |

| q | replace |

| 9 - | Bolt. |

| q | 10 Nm |

| 10 - | Oil pipe |

| 11 - | Oil guide „I“ |

| 12 - | Oil guide „II“ |

| 13 - | Thrust washer |

| q | Marked with colour |

| q | Do not confuse with the intake → Itemcamshaft |

| 14 - | Chain for oil pump |

| q | Removing and installing → Chapter>>>>>>>> |

| 15 - | Pulley set „I“ |

| q | Removing and installing → Chapter>>>>>>>> |

| q | Replace → Chapter |

| q | After replacing, the securing ring → Item and the shim must → Item be measured again to fit → Chapter |

| 16 - | Circlip |

| q | For bearing „C“ |

| 17 - | Bearing „C“ |

| q | Roller bearing for pulley set „I“ |

| q | Removing and installing → Chapter>>>>>>>> |

| 18 - | Oil pipe |

| q | With compression rings |

| q | Removing and installing → Chapter>>>>>>>> |