| –

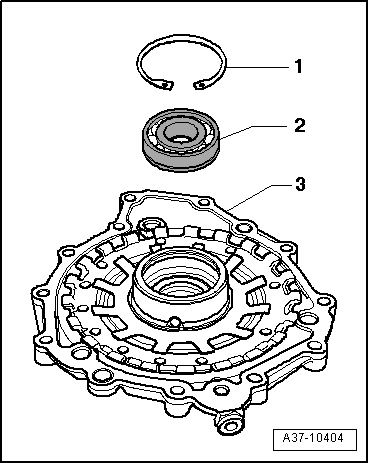

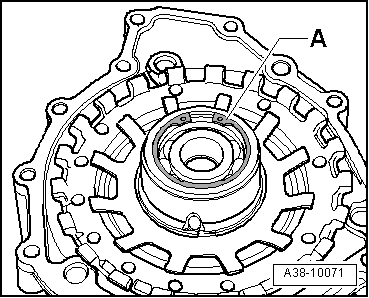

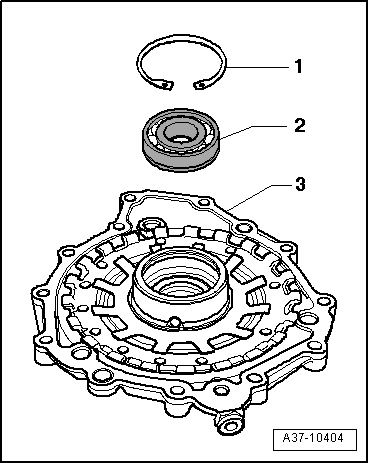

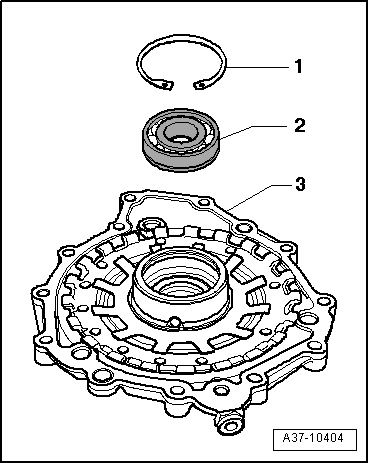

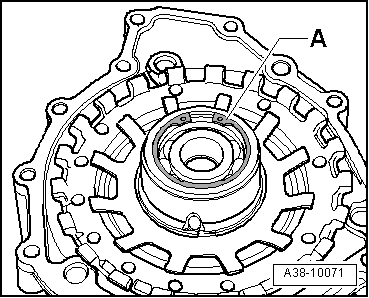

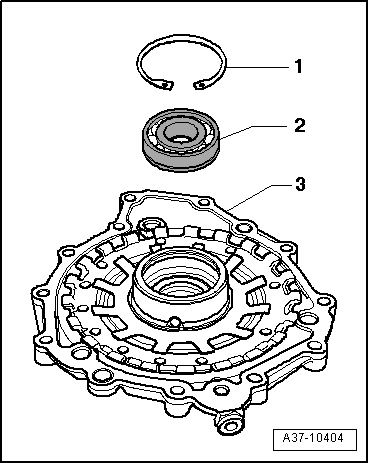

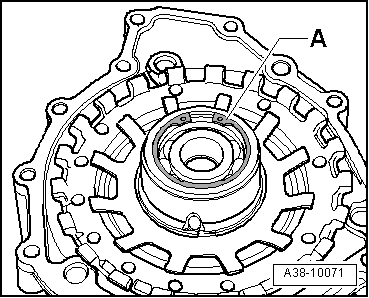

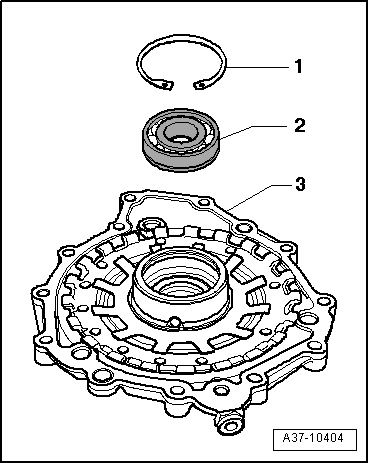

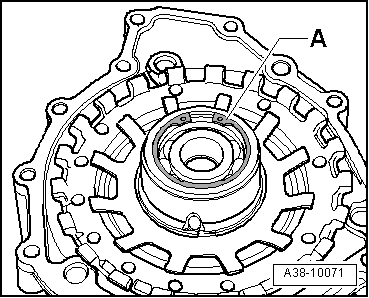

| If the contact surface and the cover are damaged, replace the bearing „A“-item 2- (ball bearing for input shaft). |

| –

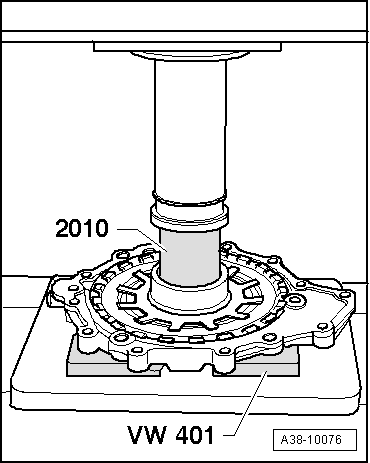

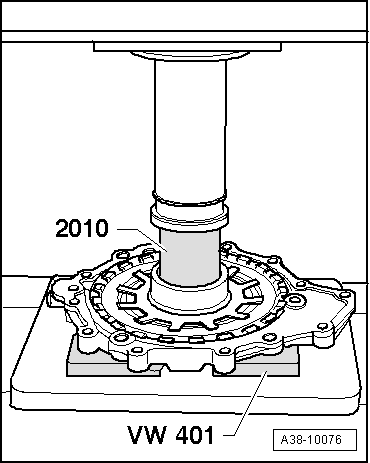

| Clean ball bearing seat in cover. |

Caution | Observe the position of the bearing „A“-item 2- (ball bearing for input shaft): the housing of the ball bearings must point downwards in the cover and the open side of the ball bearing must point upwards. Therefore, you must be able to see the balls in the bearing when fitting. |

|

| –

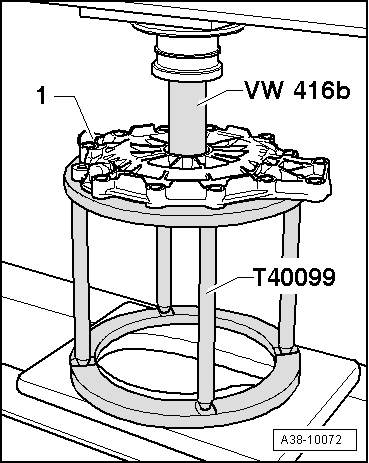

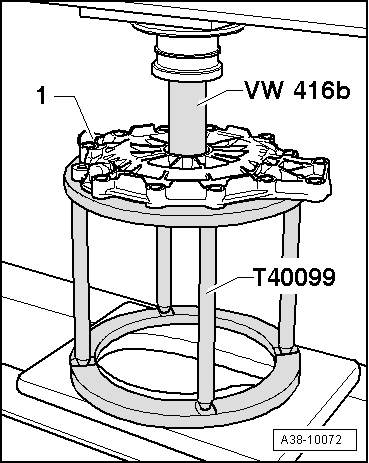

| Fit ball bearing so that it is seated flush and then press in by hand straight and as far as possible. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note