Fabia Mk2

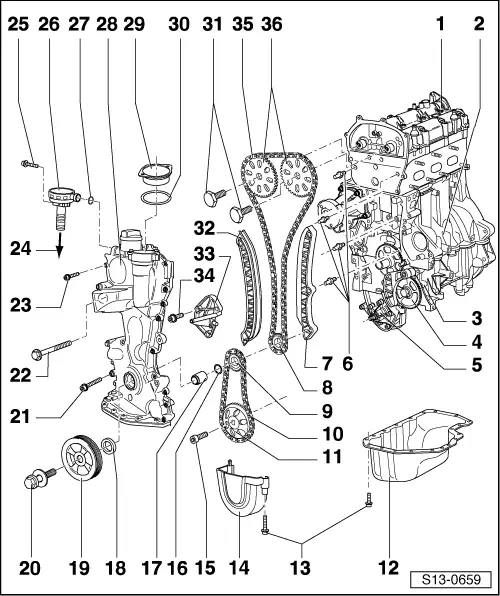

| 1 - | Cylinder head with cover |

| q | removing and installing → Chapter |

| 2 - | Cylinder block |

| q | 2 part |

| q | do not separate |

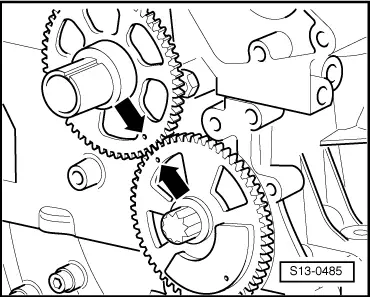

| 3 - | Balancing shaft |

| 4 - | Balancing shaft gear |

| q | do not remove |

| q | Wheel position for crankshaft gear → Fig. |

| 5 - | Oil pump |

| q | removing and installing → Chapter |

| 6 - | Bolt, 18 Nm |

| q | for tensioning rail or possibly also guide rail |

| 7 - | Guide rail |

| 8 - | Chain sprocket on the crankshaft for the camshaft drive |

| q | interlocked with spring on the crankshaft |

| 9 - | Chain sprocket on the crankshaft for the oil pump drive |

| q | not interlocked on the crankshaft |

| 10 - | Oil pump chain |

| 11 - | Oil pump sprocket |

| 12 - | Oil pan |

| q | removing and installing → Chapter |

| 13 - | 9 Nm |

| 14 - | Cover |

| q | for chain sprocket of the oil pump |

| 15 - | 20 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 16 - | O-ring |

| q | replace if damaged |

| 17 - | Housing |

| q | replace together with O-ring (Pos. 16) |

| q | fit onto cleaned crankshaft |

| q | install only after putting the timing case in place, otherwise the gasket ring can be damaged |

| 18 - | Sealing ring |

| q | replace if damaged → Chapter |

| q | replace together with housing (Pos. 17) |

| q | for crankshaft on the belt pulley side |

| q | Neither grease nor oil sealing lip of gasket ring |

| q | before installing remove grease residue on the housing with a clean cloth |

| 19 - | Belt pulley - crankshaft |

| 20 - | 150 Nm + torque a further 180° (1/4 turn) |

| q | replace |

| q | interlock the crankshaft with fixing bolt -T10121- for removing and installing → Chapter |

| 21 - | 25 Nm |

| 22 - | 50 Nm |

| 23 - | 8 Nm + torque a further 90° (1/4 turn) |

| q | if no blue sealing compound is left in the thread of the M6 screws, replace the screws for ones which have sealant on them |

| 24 - | To intake manifold |

| q | Overview of intake manifold → Chapter |

| 25 - | 10 Nm |

| 26 - | The vacuum regulating valve (PCV valve) |

| q | Pay attention to the part number |

| 27 - | O-ring |

| q | replace if damaged |

| 28 - | Timing case |

| q | removing and installing → Chapter |

| 29 - | Cover |

| 30 - | O-ring |

| q | replace if damaged |

| 31 - | 50 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | for removing and installing, interlock camshafts with camshaft fixer/locator -T10123- → Chapter and use the counterholder -T10172- → Chapter |

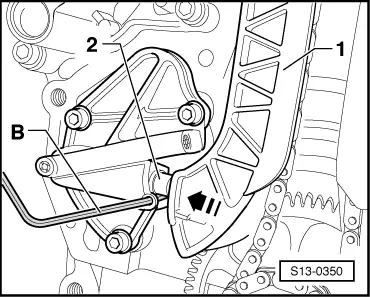

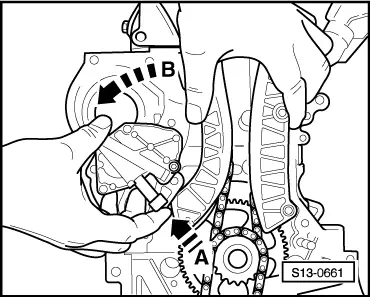

| 32 - | Tensioning rail |

| q | interlock tensioner → Fig. |

| 33 - | Hydraulic control chain tensioner |

| 34 - | 9 Nm |

| 35 - | Timing chain |

| 36 - | Camshaft sprocket |

| q | removing and installing, setting the timing → Chapter |

|

|

|

|

|

|

WARNING

WARNING