Octavia Mk2

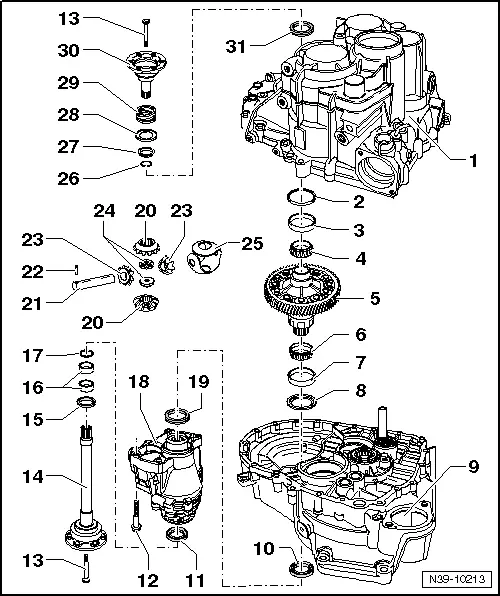

| Summary of components - vehicles with four-wheel drive |

Note

Note| t | Before installing heat the inner ring of the tapered-roller bearing to 100°C. |

| t | Replace both tapered-roller bearings together. |

| t | When replacing the tapered-roller bearings, the differential housing, the gearbox housing or the clutch housing, set the differential gear → Chapter. |

| 1 - | Gearbox housing |

| 2 - | Adjusting washer |

| q | for differential gear |

| q | Determine thickness → Chapter |

| 3 - | Outer ring/tapered-roller bearing |

| q | removing → Fig. |

| q | pressing on → Fig. |

| 4 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 5 - | Differential gear housing |

| q | with riveted pinion for final drive |

| 6 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 7 - | Outer ring/tapered-roller bearing |

| q | removing → Fig. |

| q | pressing on → Fig. |

| 8 - | Pressure washer |

| q | Fitting position: the shoulder on the inside diameter points towards the angular gearbox Pos. 18 |

| 9 - | Clutch housing |

| 10 - | Sealing ring |

| q | between manual gearbox and angle gearbox |

| q | replace → Chapter |

| q | pull out using ejection lever -MP3-418- or ejection lever -T20143/2- |

| q | on disassembled gearbox it can be driven in with pressure plate -T40007- up to the stop |

| 11 - | Sealing ring |

| q | for right flange shaft |

| q | diameter of left and right differ |

| q | replace with installed manual gearbox with angle gearbox → Chapter |

| 12 - | 40 Nm + torque a further 90° |

| q | 4 pieces |

| q | always replace → Electronic Catalogue of Original Parts |

| 13 - | 33 Nm |

| q | screw into threaded piece Pos. 24 |

| 14 - | Right flange shaft |

| q | removing and installing → Chapter |

| 15 - | Sealing ring |

| q | to replace, remove the needle bearings (polygon bearing ) pos. 16 |

| 16 - | Needle bearing (polygon bearing) |

| q | replace → Chapter |

| 17 - | Circlip |

| q | always replace → Electronic Catalogue of Original Parts |

| 18 - | Angle gearbox |

| q | Removing and installing with gearbox fitted → Chapter |

| q | Removing and installing with gearbox removed → Chapter |

| 19 - | Sealing ring |

| q | between angle gearbox and manual gearbox |

| q | replace with angle gearbox removed → Chapter |

| 20 - | Differential bevel gear, large |

| q | installing → Fig. |

| 21 - | Differential bevel gear shaft |

| q | removing → Fig. |

| q | installing → Fig. |

| 22 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

| q | removing → Fig. |

| q | drive in the new tensioning sleeve → Fig. flush |

| 23 - | Differential bevel gear small |

| q | installing → Fig. |

| 24 - | Threaded part |

| q | installing → Fig. |

| 25 - | Stop disc compound |

| q | insert with gear oil |

| 26 - | Circlip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

| 27 - | Conical ring |

| q | with slots (if present) for thrust washer catch |

| q | Fitting position: Cone towards differential gear housing |

| 28 - | Thrust washer |

| q | Fitting position: Collar to pressure spring, legs (if present) to conical ring |

| 29 - | Pressure spring for left flange shaft |

| q | fitted behind left flange shaft |

| 30 - | Flange shaft left |

| 31 - | Sealing ring |

| q | for left flange shaft |

| q | diameter of left and right differ |

| q | replace with installed gearbox → Chapter |