|

Body Repair Using Adhesion and Welding

"Adhesion" is understood to be the joining of identical or

different materials by means of an inorganic or organic compound at

room temperature or with moderate heating. The practical

application of the adhesion method is limited to self-supporting

parts of the body (outer panelling of doors, outer rear quarter

panels). This application must not be used for load-bearing parts,

e.g. frames, members.

The costs of repair and maintenance of a vehicle have a great

influence on its appeal to the customer and therefore contribute to

its competitiveness.

Therefore, it is obvious that cost development must be

constantly supervised, and that work methods that reduce costs be

developed.

The adhesion method developed by Opel and geared to the

requirements of body repair is the logical consequence of

developing and successfully applying to the automotive field modern

techniques that have proven useful and economical in other fields

of industry, such as aviation design.

The corrosion protection adhesive sealing system is available

from Aftersales.

The new product involves the known 2-component adhesive, used

previously when replacing the outer panelling (doors). The

description of processing the 2-component structural adhesive with

the Betagun have been replaced by a new generation of adhesive and

processing using cartridges, battery-powered guns which can be

regulated and compressed air guns. You will find more detailed

information in the video VT 54 and the DVT for the video.

|

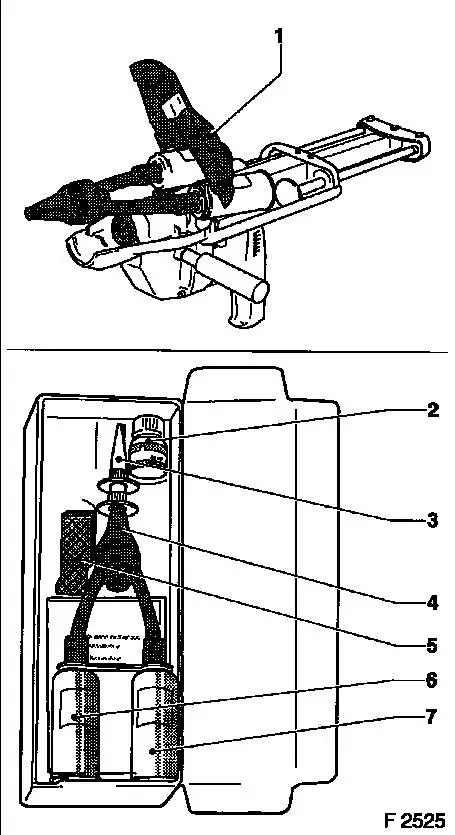

The adhesive is applied using the familiar BETAGUN 2000 (1).

The applicator ensures 100% mixture of both adhesive

components.

Contents of Adhesive Set

|

2

|

Activator

|

|

|

|

|

3

|

Two nozzles

|

|

|

|

|

4

|

Mixing head

|

|

|

|

|

5

|

Cleaning cloth

|

|

|

|

|

6

|

Cartridge, adhesive component A – 125 ml

|

|

|

|

|

7

|

Cartridge, adhesive component B – 125 ml

|

|

|

General

|

In production plants the door outer panelling and the door inner

panelling as well as the outside and inside rear quarter panels in

the wheel housing area, fuel filler port and rear lamp insert are

assembled additionally with putty adhesive and partially reduced

spot welding. The remaining flanges will continue to be machined as

before.

Door outer panelling.

|

|

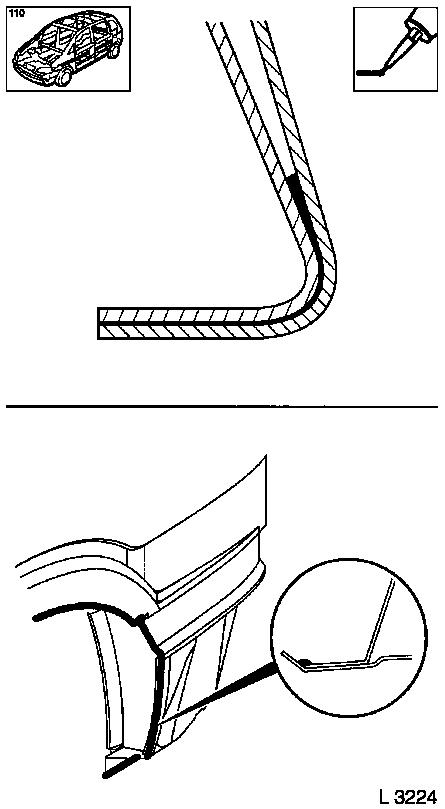

Body Sides / Partial Replacement of Outside Rear Quarter

Panel.

Description of operation and application:

- Observe work safety regulations (see parts and product

characteristics)

|

- Remove attaching parts and rear quarter panel

|

- Remove adhesive residue from inner rear quarter panel and

flange down to bare metal.

|

|

|

Note: The adhesive in

the area of the separation points / edge welds must be protected

against burning by applying heat barrier paste to the adjoining

sheet metal parts.

|

Note:

|

- Never apply weld paint to bright-finished adhesive

flanges.

|

- Flange down adhesive surface of new part only in spot-weld area

(including zinc-plated sheet metal parts)

|

- Fit new part in, note separation lines.

|

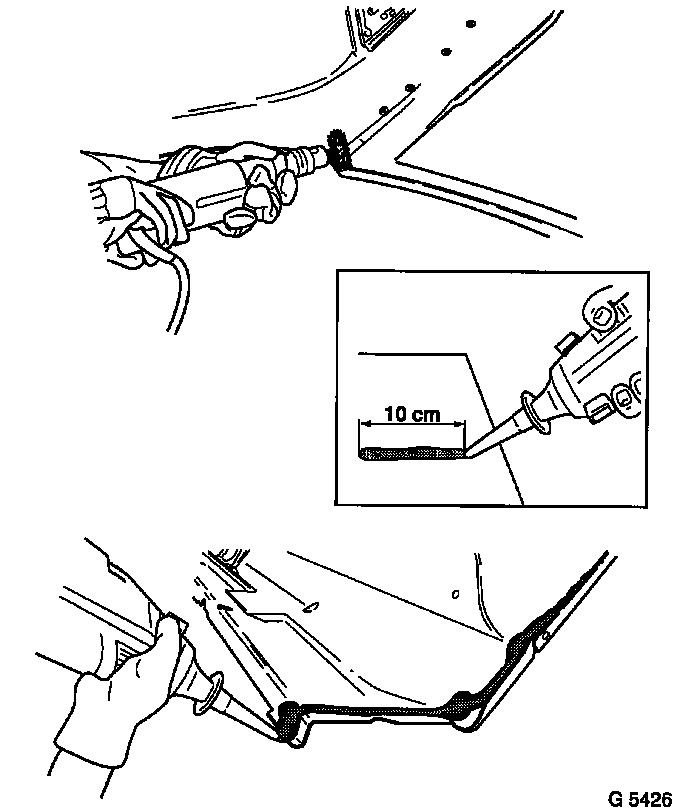

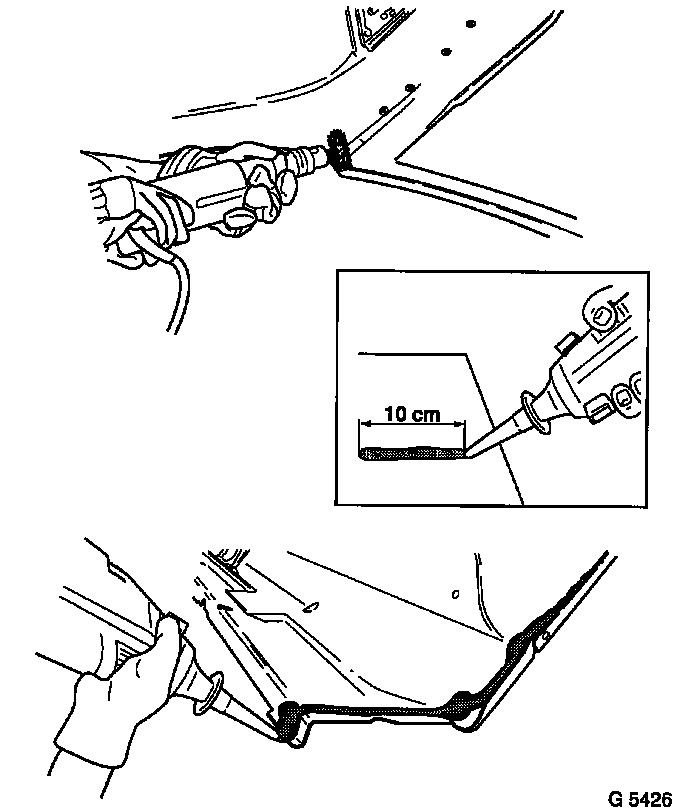

- Activate adhesive surfaces (new primed part) with activator

from adhesive kit, insert adhesive cartridges from adhesive kit in

BETAGUN 2000, apply 10 cm test bead (on cardboard).

|

- Trim cartridge nozzle (circular nozzle) to 4 mm diameter.

|

- Quickly apply adhesive bead, install new part

|

|

|

|