|

Time Allowances (hrs)

The division of the preparatory operations is as follows:

Coarse putty operations and sealing operations come under sheet

metal operations in group A. Fine putty operations come under the

paint operations in group B.

Paintable surfaces are to be produced in the sheet metal work

division (body workers, panel beaters).

The paint operations division (painters) takes over the work

from the sheet metal work division and completes the surface to be

painted. This includes: at most 3 fine putty coats for screw parts,

at most 4 fine putty coats for welded parts

Note: Spraying colour

samples for the painting of individual parts is included in the

set-up time.

Finding the right colour

|

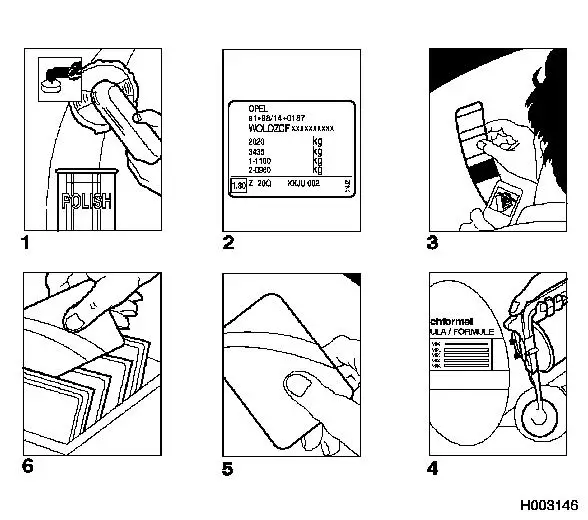

| 1. |

Clean a hand-sized area. Polish the damaged area

and adjoining surface using rubbing compound. |

| 2. |

Look for the colour code on the vehicle

identification plate (check for touching-up) |

| 3. |

Compare colour found on vehicle with colour

roster/colour shade roster. |

| 4. |

Select the mixture recipe after identifying the

colour. |

| 5. |

Carry out a colour test as a rough comparison with

colour sample to check the colour in daylight or suitable

artificial light. |

| 6. |

Keep the sample. |

|

The time allowances for paint operations in the main and

combined operations are organised into the following stages:

|

Paint stage / individual-part painting

|

Sheet metal parts

|

|

I

|

New part painting

- Partial application of putty for welded-in parts –

attached sheet metal parts

- Apply filler to entire surface area

- Apply top coat to entire surface area

|

|

II

|

Surface painting

- Apply top coat to entire surface area, including minor repairs

(not including putty operations)

|

|

III

|

Repair painting

- Partially apply putty to worked area covering up to 50% of the

surface to be painted

- Apply filler to worked surface

- Apply top coat to entire surface area

|

|

Paint stage / blending

|

Metal parts (2-coat / 3-coat paint

applications)

|

|

II a

|

Blend-in painting

- Blend-in basefix to approx. 50% into the adjoining part

|

|

II b

|

Touching-up

- Blend-in basefix into the entire adjoining part

|

|

Paint stage / individual-part painting

|

Plastic parts

|

|

I

|

New part painting

- Apply top coat to entire surface area

|

|

II

|

Surface painting

- Apply filler to entire surface area

- Apply top coat to entire surface area

|

|

III

|

Repair painting

- Apply putty to the worked area covering up to approx. 30% of

the component surface

- Apply filler to entire surface area

- Apply top coat to entire surface area

- Create structure if required (structure spray)

|

|