|

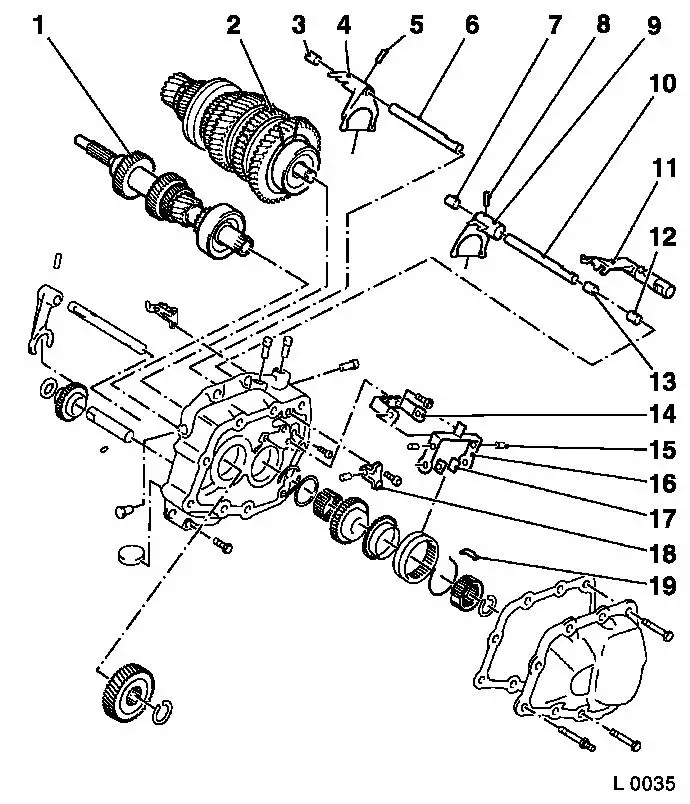

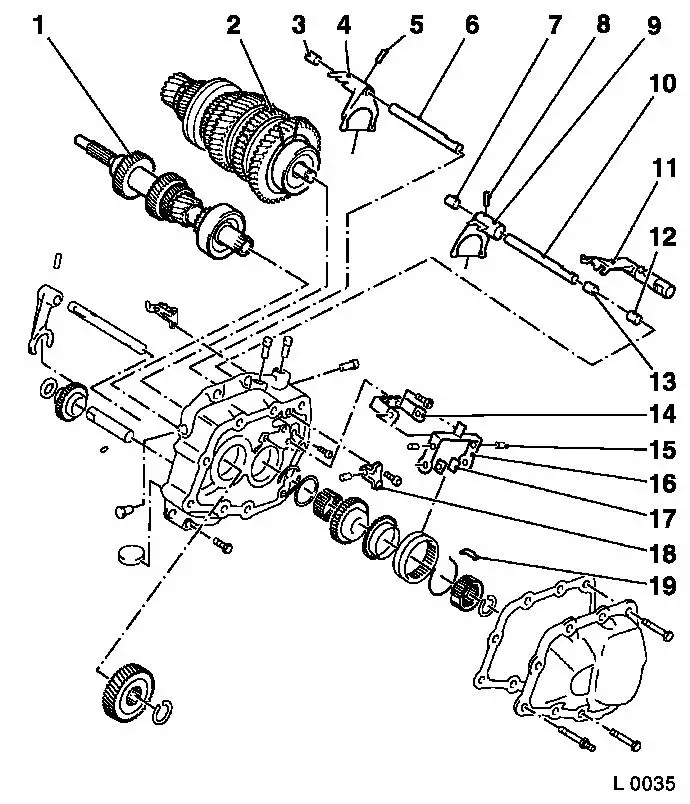

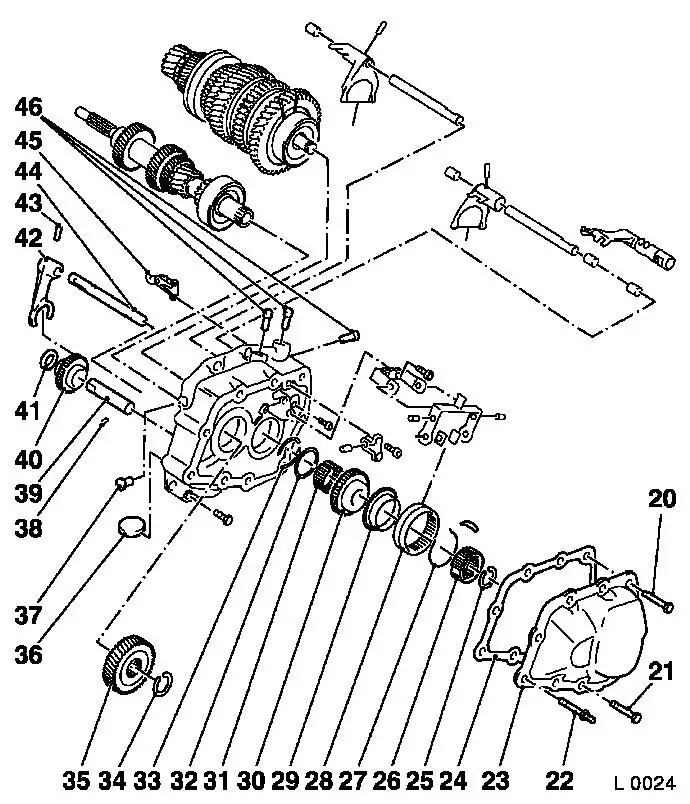

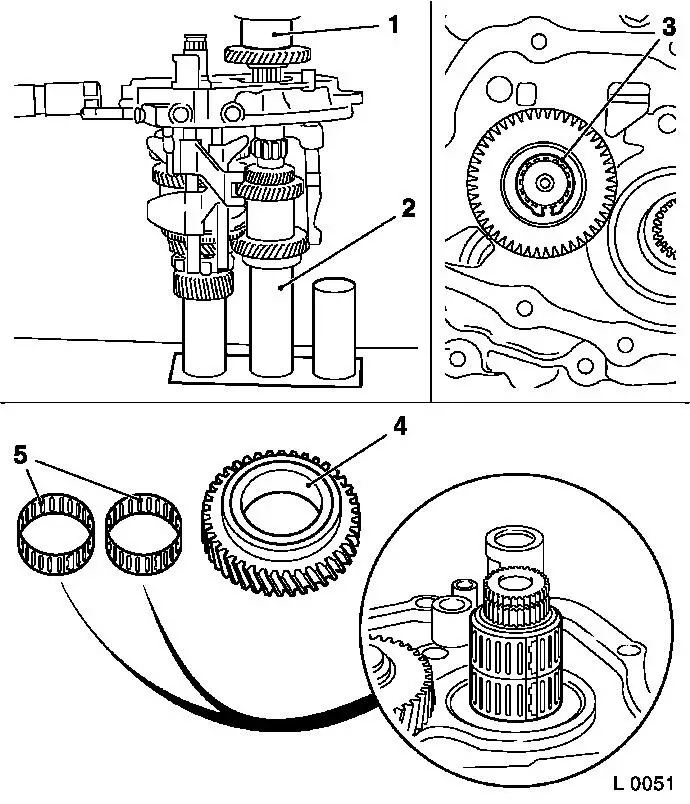

End Shield, Dismantle and Assemble (F13)

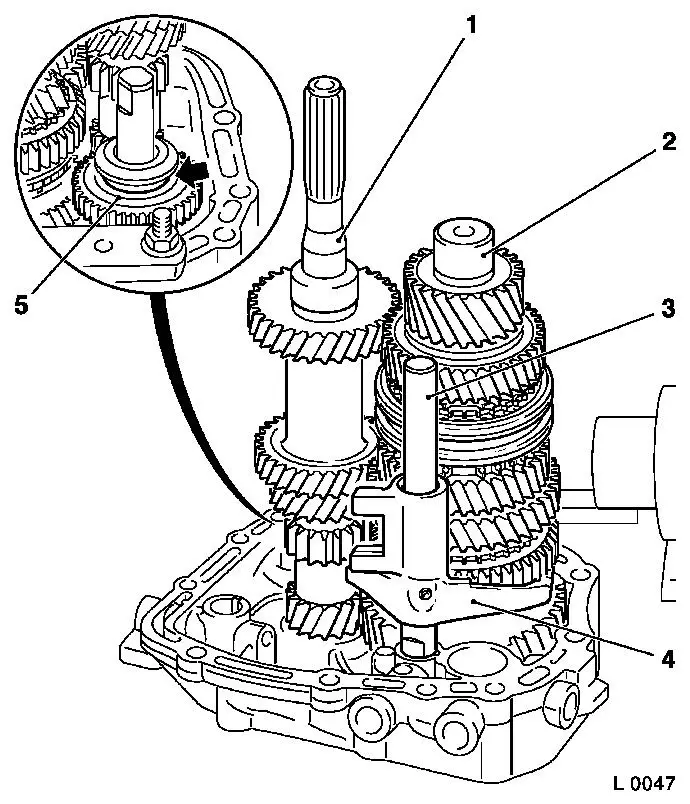

Illustration

| 1. |

Drive shaft |

| 2. |

Main shaft |

| 3. |

Teflon bushing |

| 4. |

1st/2nd gear shift fork |

| 5. |

Roll pin |

| 6. |

1st/2nd gear shift rod |

| 7. |

Teflon bushing |

| 8. |

Roll pin |

| 9. |

3rd/4th gear shift fork |

| 10. |

3rd/4th gear shift rod |

|

|

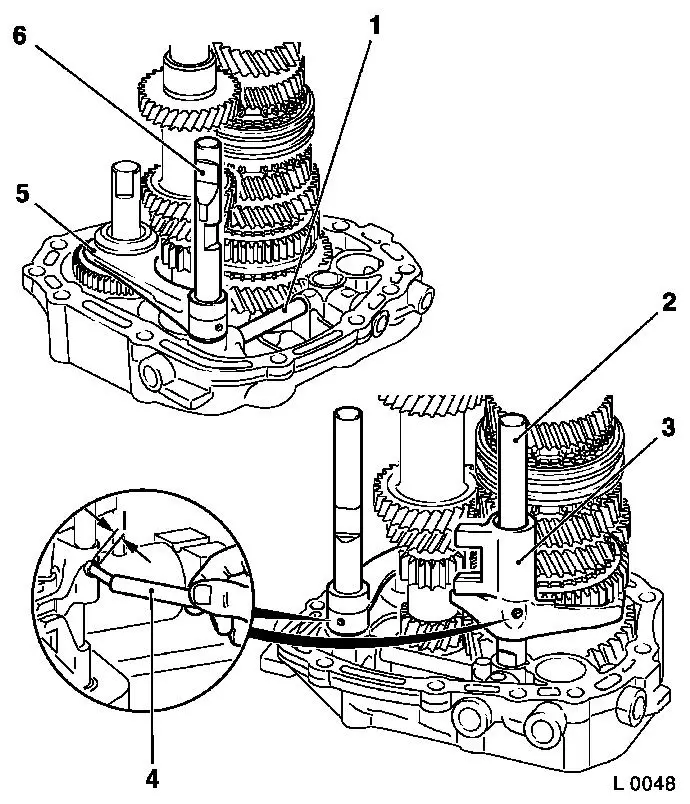

Illustration

|

11

|

5th gear shift driver

|

|

12

|

Teflon bushing

|

|

13

|

Teflon bushing

|

|

14

|

Bearing support

|

|

15

|

Pin

|

|

16

|

Rocker arm

|

|

17

|

Crosshead shoe

|

|

18

|

Bridge with locking pin

|

|

19

|

Sliding block

|

|

|

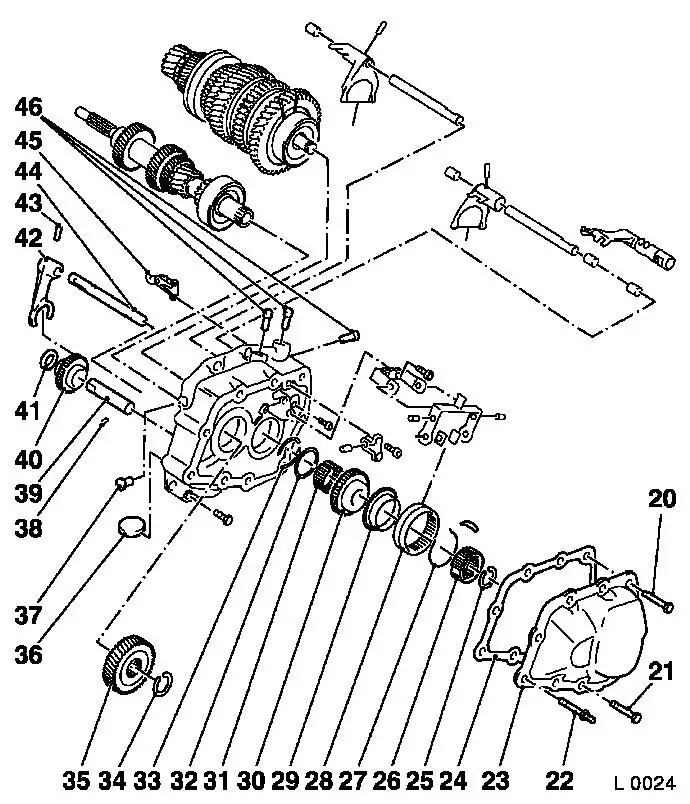

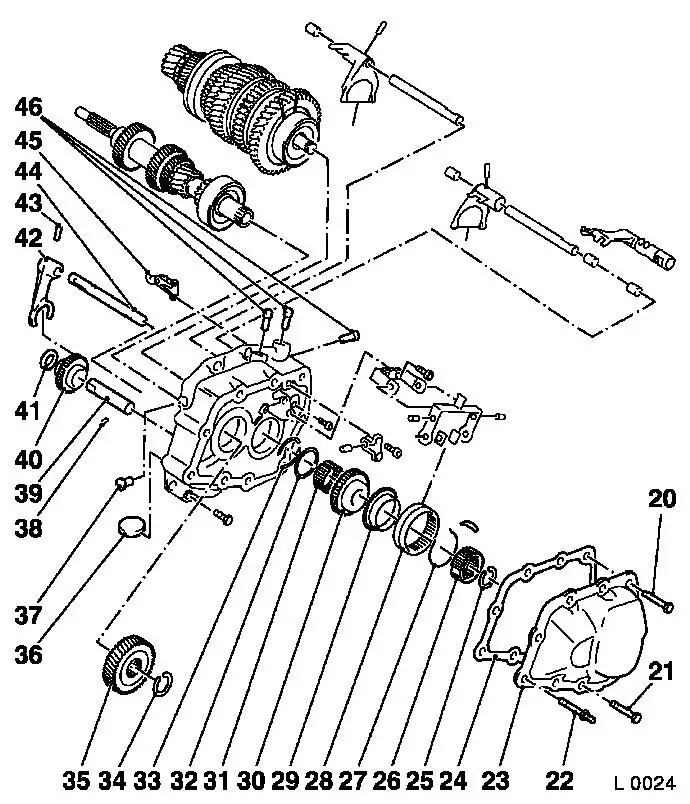

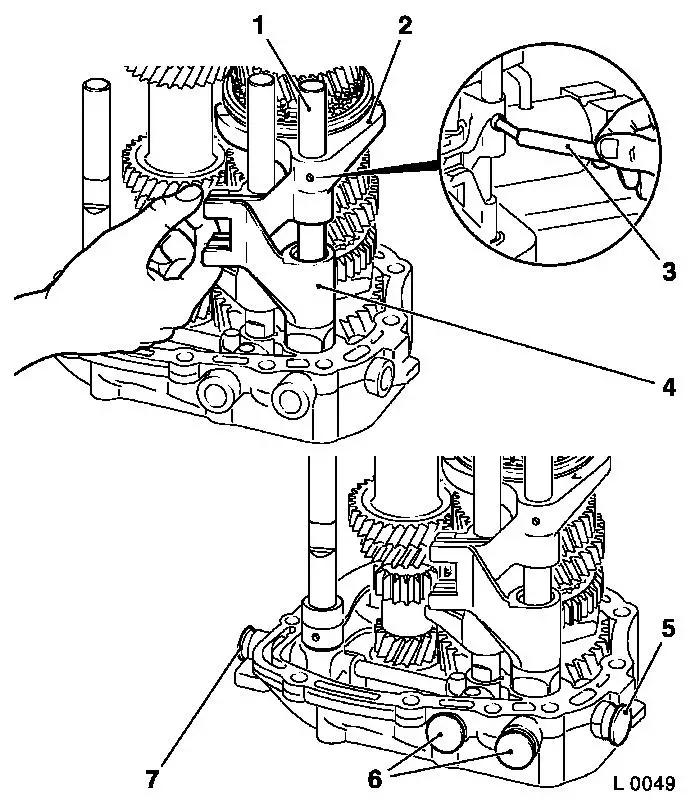

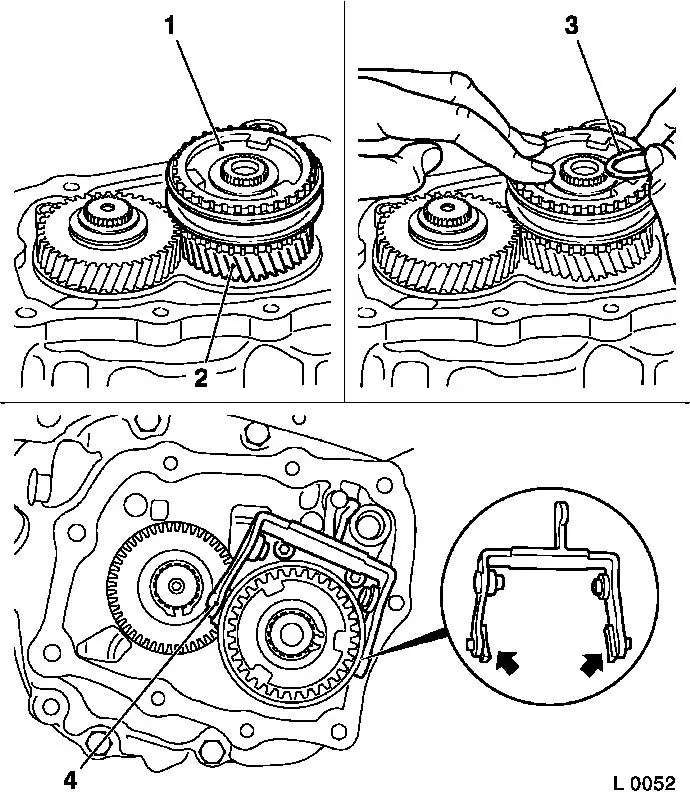

Illustration

|

20

|

Fastening bolt M8

|

|

21

|

Fastening bolt M7

|

|

22

|

Fastening bolt

|

|

23

|

End shield cover

|

|

24

|

Gasket

|

|

25

|

Retaining ring

|

|

26

|

5th gear synchromesh body

|

|

27

|

Synchroniser spring

|

|

28

|

5th gear shift sleeve

|

|

29

|

5th gear synchroniser ring

|

|

|

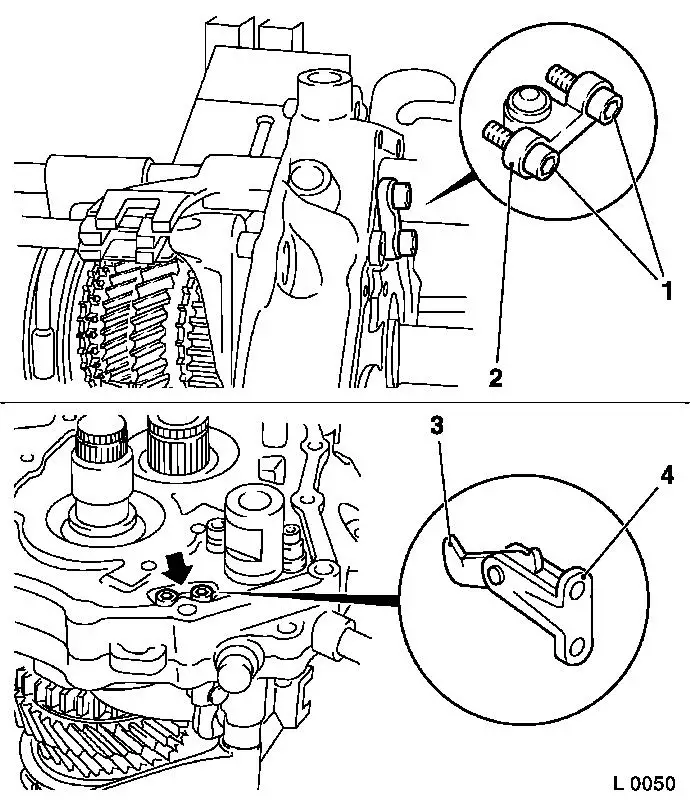

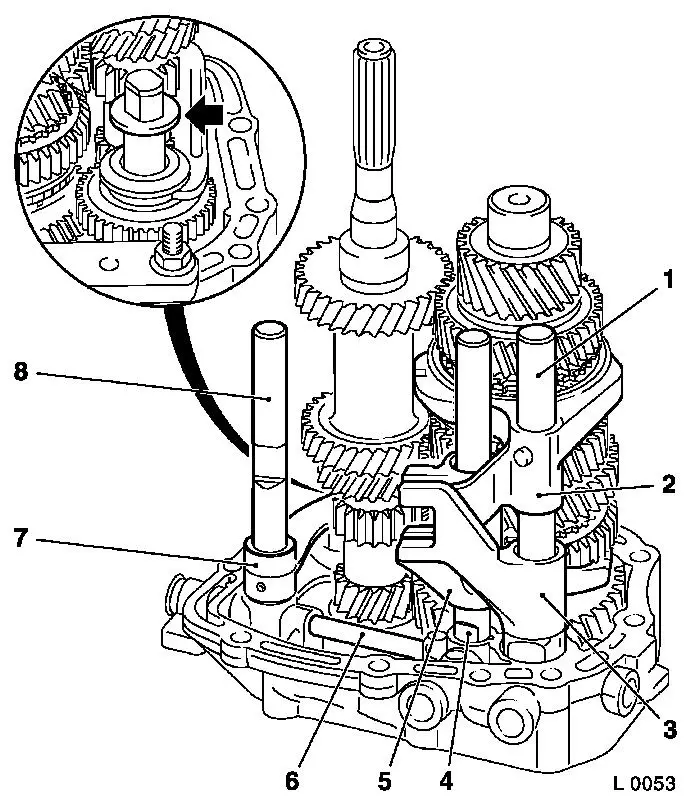

Illustration

|

30

|

5th gear (driven)

|

|

31

|

Needle bearing

|

|

32

|

Retaining ring

|

|

33

|

Thrust washer

|

|

34

|

Retaining ring

|

|

35

|

5th gear (driving)

|

|

36

|

Magnet

|

|

37

|

Locking plugs

|

|

|

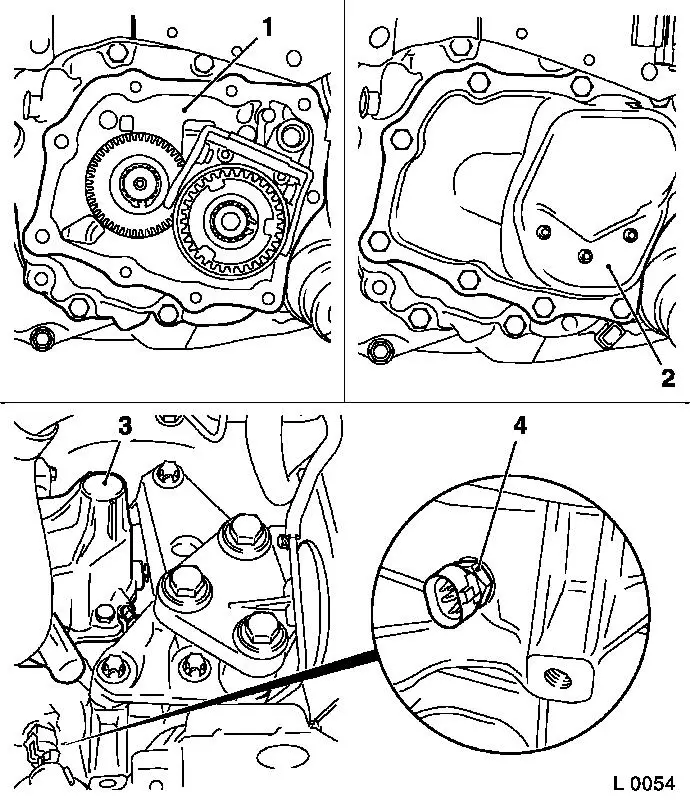

Illustration

|

38

|

Ball

|

|

39

|

Reverse gear shaft

|

|

40

|

Reverse gear

|

|

41

|

Thrust washer

|

|

42

|

Reverse gear shift fork

|

|

43

|

Roll pin

|

|

44

|

Reverse gear shift rod

|

|

45

|

Pawl

|

|

46

|

Locking plugs

|

|

|

|

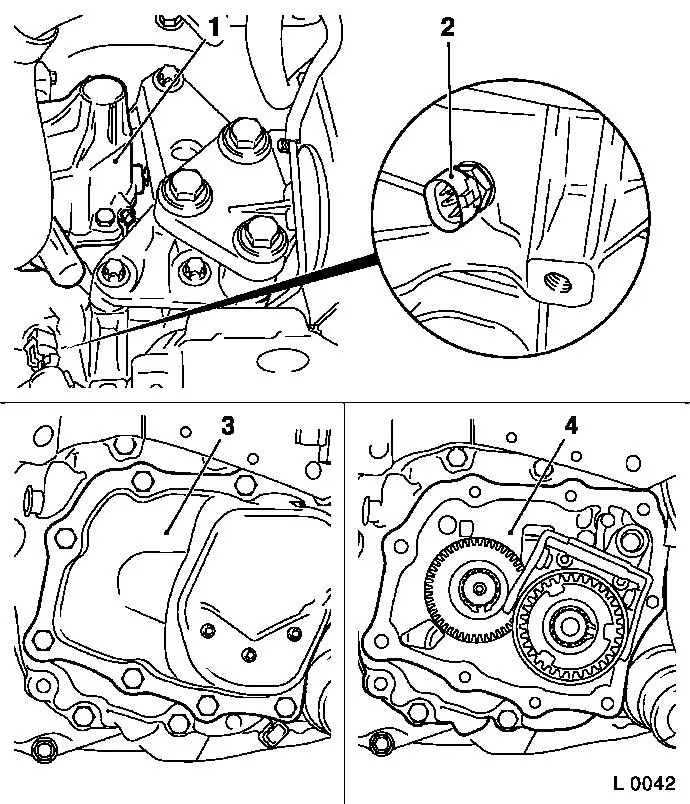

Note: Transmission

remains installed.

Remove Remove

Remove gearshift cover (1) – see operation "Gearshift

Cover, Remove and Install and/or Seal (F13/F17/F17+/F18)".

Remove reversing lamps switch (2).

Remove end shield cover (3) – see operation "Gasket for

End Shield Cover, Replace (F13/F17/F17+/F18)".

Remove end shield (4) from transmission – see operation

"Gasket for End Shield, Replace (F13/F17/F17+/F18)".

|

|

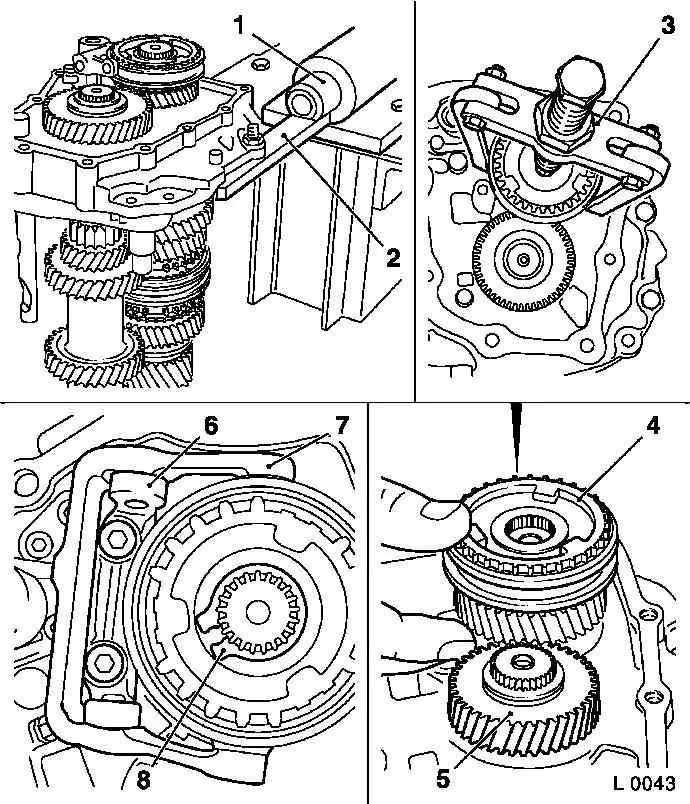

Install

Install

|

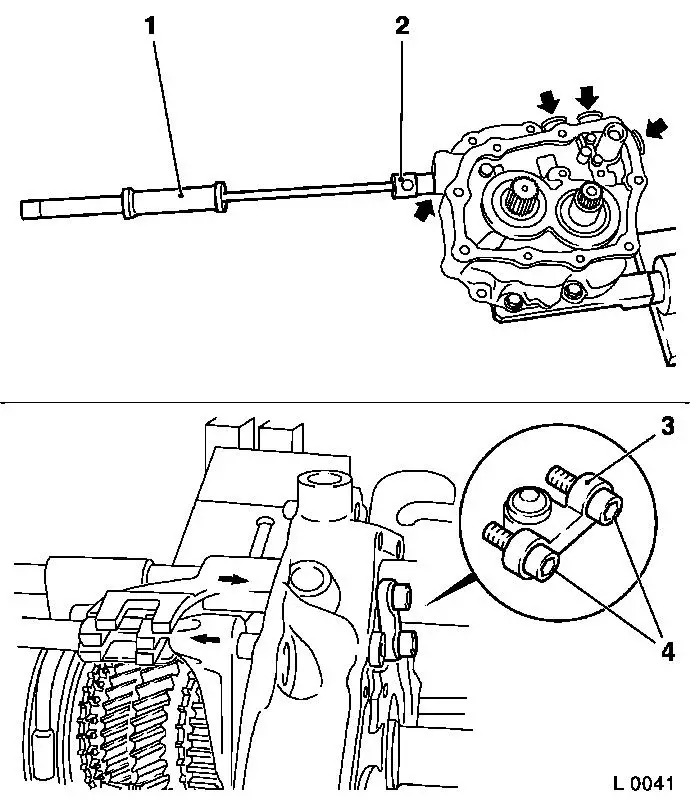

Attach end shield to KM-552 (2). Attach KM-552 to KM-113-2

(1).

Remove Remove

Remove bearing support (6) with rocker arm (7) from end shield

(2 fastening bolts).

Caution

Micro-encapsulated fastening bolts. If fastening bolts are

stiff, heat end shield with hot-air dryer to approx. 80 °C.

Disassemble

Disassemble

Remove retaining ring (8) from synchromesh body. Remove 5th gear

(4) synchromesh body with 5th gear (5) (small) from main shaft, if

stiff use KM-161-B (3). Remove both needle cages for 5th gear.

|

|

Disassemble

Disassemble

|

Remove retaining ring (1) of 5th gear (driving) (2) from drive

shaft (3).

Place thrust piece (5) for KM-553-A (4) on drive shaft. Remove

5th gear (driving) from drive shaft with KM-553-A. Ensure correct

seating of KM-553-A on 5th gear (driving).

Remove bearing support (7) with rocker arm (6) from end shield

– 2 fastening bolts (arrow).

Caution

Micro-encapsulated fastening bolts. If fastening bolts are

stiff, heat end shield with hot-air dryer to approx. 80 °C.

|

|

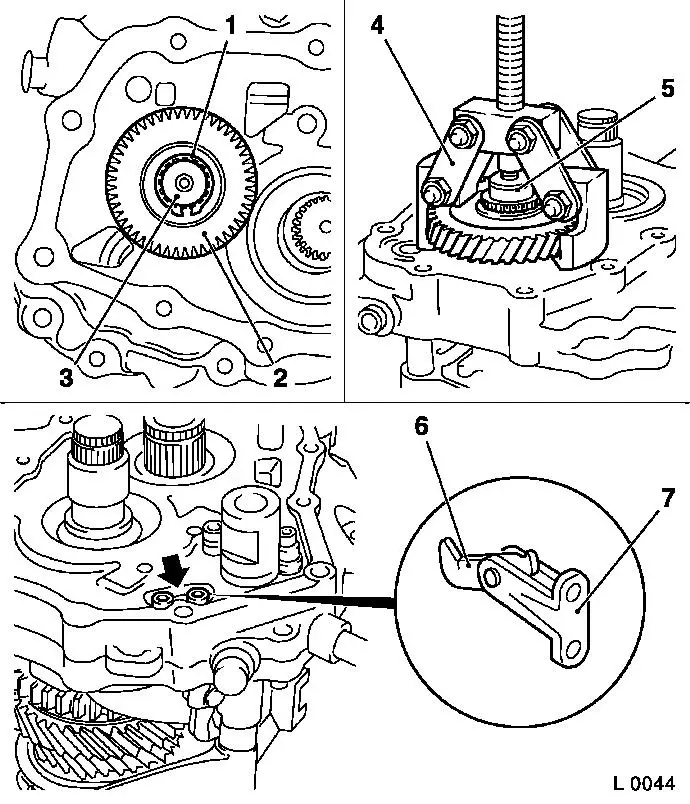

Disassemble

Disassemble

|

Remove locking plugs (arrows) with KM-727-B (2) and KM-328-B (1)

from end shield.

Remove (3) fastening bolts (4) of bridge for locking pin from

end shield.

Caution

Micro-encapsulated fastening bolts. If fastening bolts are

stiff, heat end shield with hot-air dryer to approx. 80 °C.

Disassemble

Disassemble

Engage 2nd and 5th gears (with shift driver). If 3rd gear is now

engaged, the bridge will be pushed out.

|

|

|

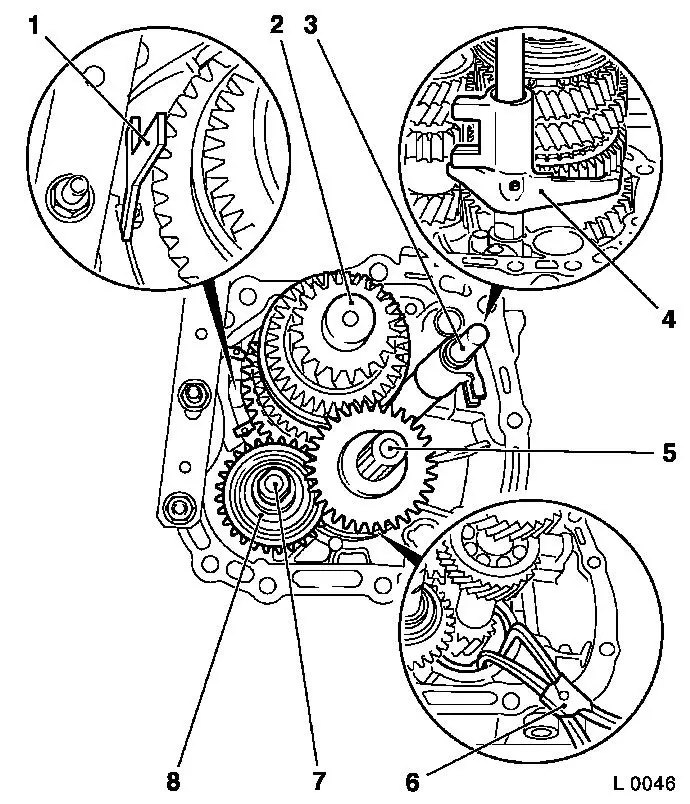

Note: Relieve

pressure on shifter rod guides – for this, support shifter

rods above with wood (1).

Disassemble

Disassemble

Drive coiled pins (arrows) out of 3rd and 4th gear shift forks

(3) and reverse shift fork (6) using drift.

Remove 3rd, 4th (3) and reverse gear (6) shifter rods (2) and

shift forks from end shield.

Remove 5th gear shift driver (4) from end shield.

Remove locking pin (5) for catch from end shield bore holes.

|

|

Disassemble

Disassemble

|

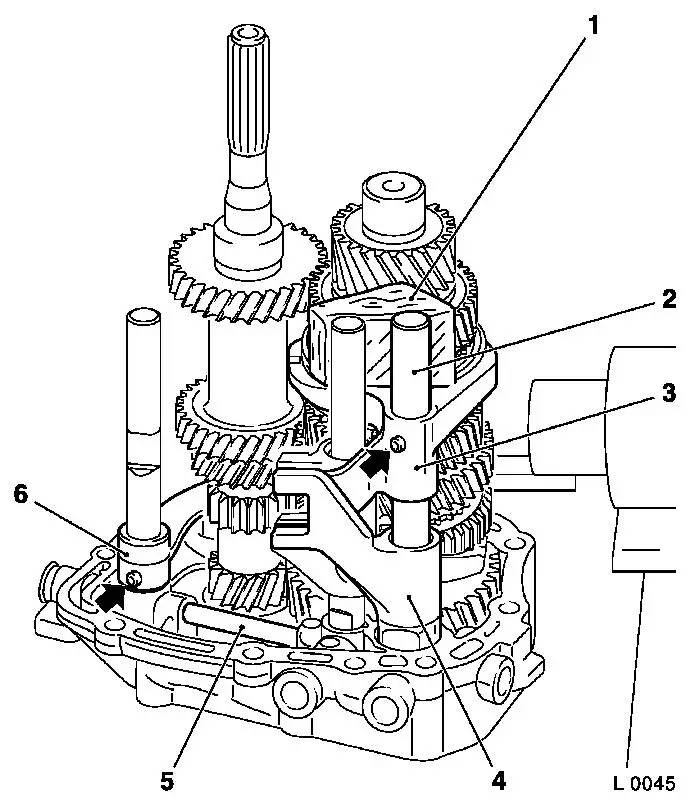

Remove retaining rings for main shaft (2) and drive shaft (5)

with KM-443-B (6) from grooves of end shield. As assembly aid,

tension retaining ring for main shaft with installation plate

(1).

Remove main shaft (2) from end shield.

Remove drive shaft (5) from end shield.

Remove reverse idler (8) from end shield.

Remove shift fork (4) and shift rod 1st and 2nd (3) gear from

end shield.

Clamp reverse gear (7) in vice with protective jaws. Carefully

knock off end shield with brass punch.

Caution

Note that retaining ball is released.

|

|

Clean Clean

Clean all parts and sealing surfaces.

Inspect

Inspect

Check parts for wear, signs of scoring, damage; if necessary

replace.

Lubricate rotating parts on their bearing, running, seating, and

pressure surfaces using transmission fluid.

Install

Install

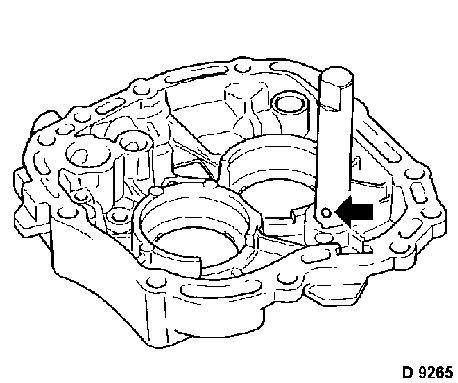

|

Press reverse gear axle with inserted lock ball (arrow) to start

in end shield.

Caution

Note installation position.

|

|

Assemble

Assemble

|

Coat bearing and reverse bore hole with transmission fluid.

Insert main shaft (2), drive shaft (1), reverse gear wheel (5)

and shift fork (4) with 1st/2nd gear shift rod (3) into end shield

and secure with new retaining ring, for this insert retaining rings

with KM-443-B.

Note: Retaining rings

must engage correctly in grooves.

Shift fork groove (arrow) for reverse idler gear (5) points

upwards.

|

|

Note: To relieve

pressure on shift rod guides in end shield, support shift rods with

wooden wedge when securing with pin.

Assemble

Assemble

|

Insert locking pin (1) reverse gear 3rd/4th.

Allow new coiled pin to protrude approx. 2 mm/0.08 in (Dimension

I).

Insert shift fork (5) and reverse gear shift rod (6) and secure

with Pin KM-308 (4).

Insert shift fork (3) and shift rod (2) for 1st/2nd gear and

insert pin with KM-308 (4).

|

|

Note: To relieve

pressure on shift rod guides in end shield, support shift rods with

wooden wedge when securing with pin.

Assemble

Assemble

|

Insert 5th gear (4) shift driver.

Insert shift fork (2) and shift rod for 3rd/4th gear (1) and Pin

KM-308 (3).

Assemble

Assemble

Fit four detent pins (5/6/7) and drive to stop with plastic

hammer or soft metal drift.

Bring shift fork into neutral speed position.

|

|

Assemble

Assemble

|

Engage 2nd/3rd/5th gear.

Coat new fastening bolts (1) with locking compound.

Position bridge (2) for locking pin on end shield and lightly

tighten with fastening bolts. Switch 1st/2nd gear shift fork to

neutral. Attach bridge fastening bolts – tightening torque 7

Nm / 5 lbf. ft.

Bring shift fork into neutral speed position.

Coat new fastening bolts (arrow) with locking compound.

Attach bearing bracket (4) with pawl (3) to end shield (2

fastening bolts) – tightening torque 9 Nm / 7 lbf. ft.

|

|

Assemble

Assemble

|

Remove end shield with KM-552 from KM-113-2.

Insert end shield with main and drive shaft into KM-554 (2).

Press on gearwheel for 5th gear (driving) with KM-514 (1).

Caution

Long gear hub points to end shield. Fit new retaining ring

(3).

Assemble

Assemble

Attach end shield with KM-552 to KM-113-2.

Coat both needle bearings (5) for 5th gear (4) with transmission

fluid and place on main shaft. Ensure correct seating of slotted

needle bearings.

|

|

Assemble

Assemble

|

Coat seating surfaces of main shaft and synchromesh body with

transmission fluid.

Slide 5th gear (2) and synchromesh body (1) onto main shaft and

secure with new retaining ring (3).

Insert crosshead shoe (arrow) in 5th gear shift fork (4).

Coat new fastening bolts with locking compound.

Attach bearing bracket with rocker arm to end shield (2

fastening bolts) – tightening torque 22 Nm / 16 lbf. ft.

|

|

Install

Install

|

Fit friction washer (arrow) on reverse gear axle.

Cement friction washer with grease.

Caution

Before installation of transmission

unit check following items for position and seating.

|

1

|

3rd/4th gear shift rod

|

|

2

|

3rd/4th gear shift fork

|

|

3

|

5th gear shift driver

|

|

4

|

1st/2nd gear shift rod

|

|

5

|

1st/2nd gear shift fork

|

|

6

|

Lock pin for gear stop

|

|

7

|

Reverse gear shift fork

|

|

8

|

Reverse gear shift rod

|

|

|

Install

Install

|

Insert end shield (1) into transmission – see operation

"Gasket for End Shield, Replace – F13/F17/F17+/F18".

Install gasket for end shield cover (2) – see operation

"Gasket for End Shield Cover, Replace –

F13/F17/F17+/F18".

Install reversing lamps switch (4) with new seal ring –

tightening torque 20 Nm / 15 lbf. ft.

Install gearshift cover (3) – see operation "Gearshift

Cover, Remove and Install and/or Seal (F13/F17/F17+/F18)".

Inspect

Inspect

Check transmission fluid level – see operation

"Transmission Fluid Level, Check and Correct

(F13/F17/F17+/F18)".

|

|

|