|

Transmission, Remove and Install

(F13/F13+/F17/F17+/F18)

Note: The following

parts must be converted when the transmission is replaced:

Only for transmission F17/F17+:

- Pressure line with fitting (vehicles up to MY 2002 only)

The drive unit must be aligned to the front axle body using KM-6173

and KM-6001-A in order to ensure correct alignment of the drive

unit after releasing the fastening bolts for the right and left

engine damping blocks. The attachment of KM-6173 and KM-6001-A is

described in the following.

Remove Remove

|

If present: Remove lower engine compartment cover – see

operation "Lower Engine Compartment Cover, Remove and Install" in

group "A".

Remove front exhaust pipe, catalytic converter and centre

muffler.

Install

Install

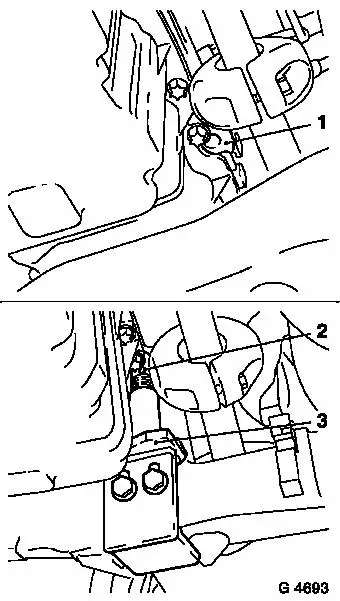

Attach KM-6173 (3) to front axle body – screw up support

bearing (2) until pins are seated flush in mount (1) on cylinder

block.

|

|

Install

Install

|

|

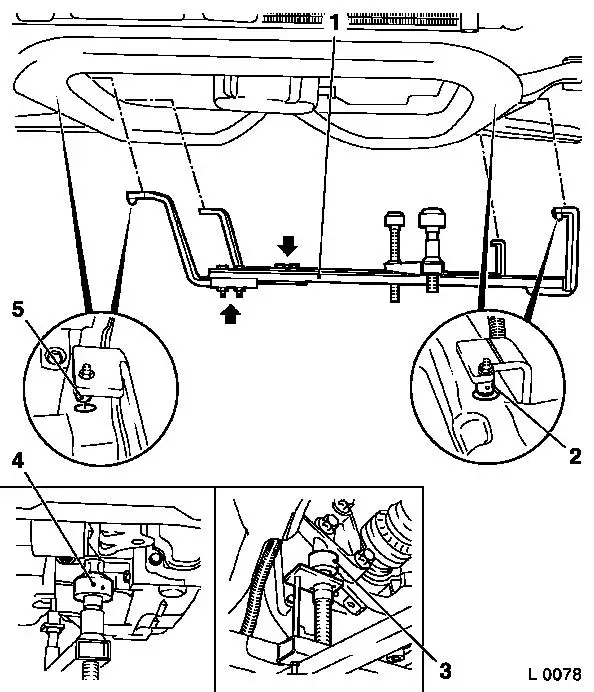

Release fastening bolts (arrows) for adjustment rails on

KM-6001-A (1).

Insert KM-6001-A as illustrated – pins (2) and (5) must

engage in guide holes of front axle body. Tighten fastening bolts

for adjustment rails.

Screw up front support bearing (4) and rear support bearing (3)

up to contact at guide pins of front engine damping block and rear

engine damping block bracket – guide pins must sit free of

play in support bearings.

Remove Remove

Remove front axle body – see operation "Front Axle Body,

Remove and Install" in group "E". The Tools KM-6173 and KM-6001-A

remain on the front axle body and must not be moved.

|

|

Remove air filter housing with air intake hose – see

illustration "Air Flow Guide" in group "J".

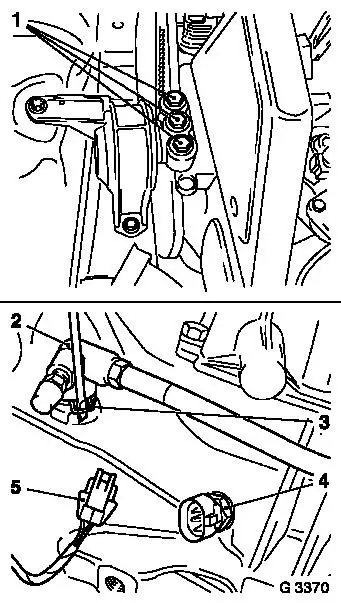

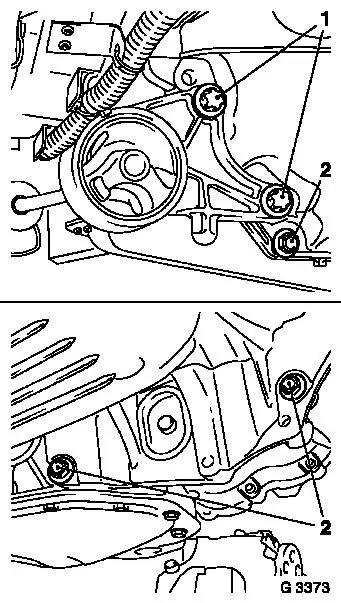

Remove fastening bolts (1) of right engine damping block from

right engine damping block bracket.

Detach wiring harness plug (5) from reversing lamps switch

(4).

Charge brake fluid reservoir to "MAX" and close off with dummy

plug.

Detach pressure line with connector (2) from central release

pressure line on clutch housing – at the same time release

and remove clamp (3) with screwdriver; then slightly bend clamp

together and re-insert in connector. Collect escaping fluid.

|

|

|

Remove left engine damping block fastening bolts (2) from left

engine damping block bracket.

Remove fastening bolts (1) for left engine damping block support

from transmission.

Remove engine damping block support.

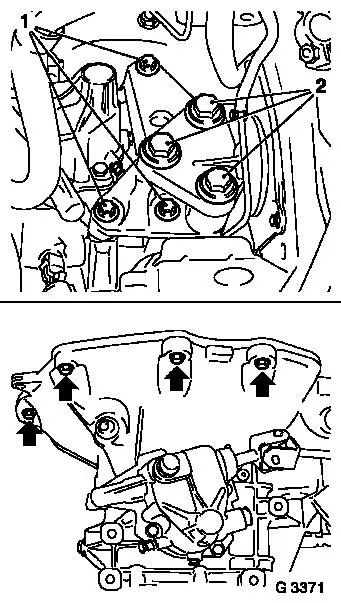

Remove four upper fastening bolts (arrows) of transmission

– if necessary, pull coolant pipe upward and secure with

cable tie.

Lower engine with transmission approx. 5 cm on MKM-883-1 –

ensure that coolant hoses and wiring harnesses are not

stretched.

|

|

Remove axle shafts from transmission – see operation "Axle

Shaft, Remove and Install" in group "E". Axle shafts remain in

wheel hubs. Attach axle shafts to underbody.

Caution

Fluid escapes – place pan underneath and close off

apertures with plug.

Remove Remove

|

Remove front engine damping block fastening bolts (1) from

transmission. Remove front engine damping block.

Remove transmission housing fastening bolts (2) at fluid

sump.

|

|

Install

Install

|

|

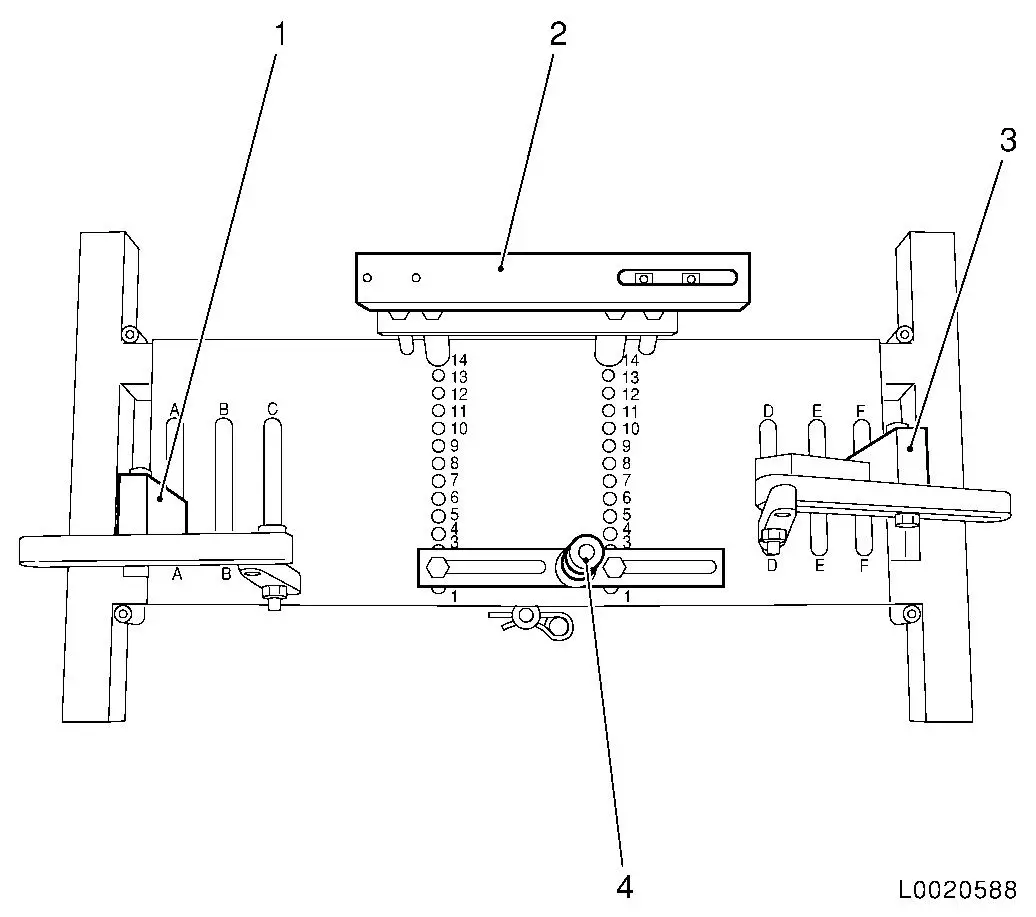

Set transmission mount DT-47648 on

KM-904 and preinstall as shown in illustration:

|

Part

|

Position on base plate

|

Name

|

|

DT-47648-2

(4)

|

2

|

Clutch housing support

|

|

DT-47648-3

(2)

|

14

|

Transmission housing support

|

|

DT-47648-5 left

(1)

|

A

|

Transmission support with swivel arm, rear

|

|

DT-47648-5 right

(3)

|

F

|

Transmission support with swivel arm, front

|

|

|

Caution

Manufacturer's instructions for transmission mount DT-47648 must

be observed.

Attach transmission mount DT-47648 to transmission

Note: Loosen all bolt

connections on the swivel arms and supports down to the base plate

before positioning. Turn the supports as far down as possible using

the spindles.

Set transmission mount DT-47648 down with supports under

transmission

Tighten the bolt connections of the supports

Attach swivel arm (1) and (2) to transmission

Tighten the bolt connections in the swivel arm from the

transmission to the base plate

Note: Align the

swivel arms to minimize the leverage forces.

|

|

|

Remove Remove

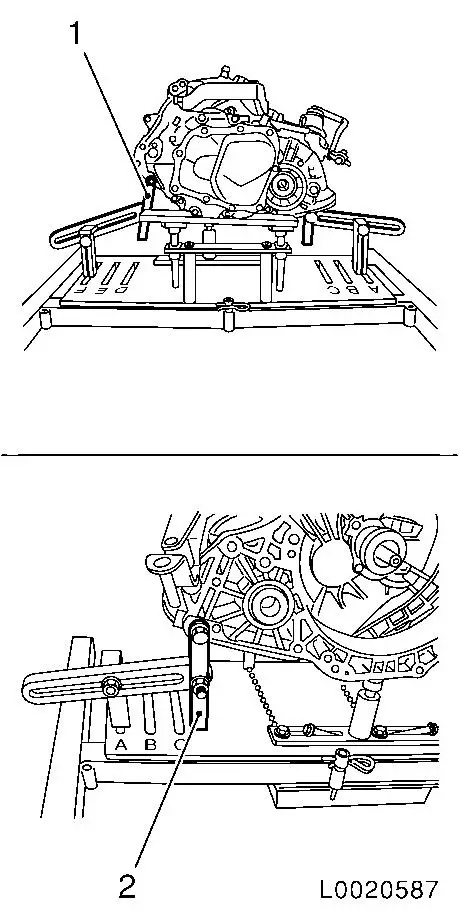

Remove front (2) and rear (1) transmission fastening bolts from

engine.

Press off transmission from engine block and carefully drain

– ensure that installation parts and wiring harnesses are not

damaged.

If necessary: Detach transmission from DT-47648.

Caution

Do not damage attaching parts when laying transmission down.

|

|

Remove Remove

Attach transmission to DT-47648.

Caution

Follow manufacturer's instructions for DT-47648.

Install

Install

Lift, align and attach transmission uniformly on engine.

Install lower front and rear transmission fastening bolts on

engine – tightening torque 60 Nm / 44 lbf. ft.

Remove Remove

Detach DT-47648 from transmission.

Install

Install

|

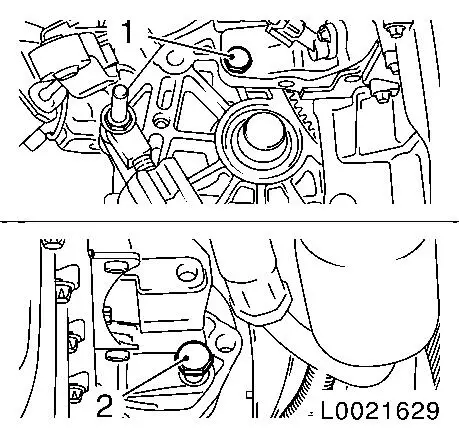

Install transmission on fluid sump – tightening torque 40

Nm / 29.5 lbf. ft.

Install front engine damping block on transmission –

tightening torque 60 Nm / 44 lbf. ft.

Detach axle shafts from underbody.

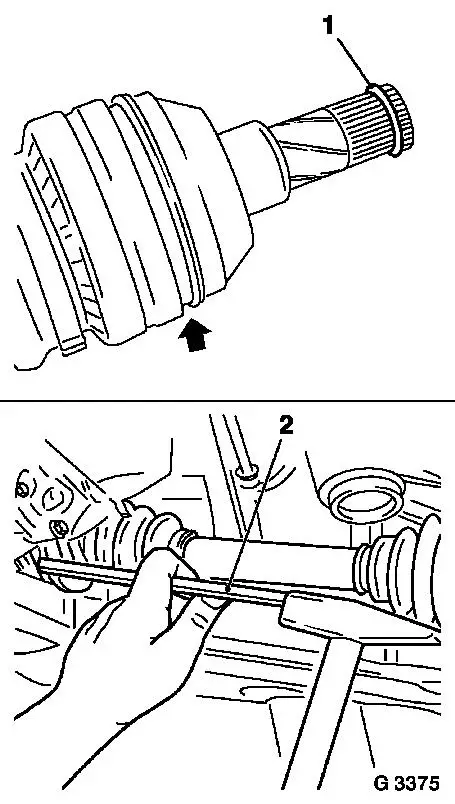

Install axle shaft in transmission: Attach new retaining ring

(1) to axle shaft.

Coat splines of axle shaft with transmission fluid.

Insert axle shafts into transmission and drive in against bead

of friction weld seam (arrow) with soft metal drift (2) or with

plastic hammer until retaining ring engages.

Move engine with transmission on MKM-883-1 into original

position.

|

|

Install front axle body – see operation "Front Axle Body,

Remove and Install" in group "E".

Caution

When installing the front axle body, ensure that support

bearings of KM-6001-A are correctly seated in the guide pins of the

front engine damping block and the rear engine damping block

bracket. Pins of KM-6173 must sit in the cylinder block mount. If

necessary: Correct installation location of engine and transmission

using MKM-883-1.

Do not yet install front exhaust pipe, catalytic converter,

centre muffler, battery and battery support.

Install

Install

Install right engine damping block on engine damping block

bracket – tightening torque 55 Nm / 41 lbf. ft.

Install air intake hose and air filter housing – see

illustration "Air Flow Guide" in group "J".

Install left engine damping block main bracket on transmission

– tightening torque 35 Nm / 26 lbf. ft. Install left engine

damping block on left engine damping block main bracket, note

different bolt lengths – tightening torque 55 Nm / 41 lbf.

ft.

Install upper fastening bolts on transmission – tightening

torque 60 Nm / 44 lbf. ft.

Insert pressure line with connection piece into central release

pressure line on clutch housing – clamp engages audibly.

Connect wiring harness plug to reversing lamp switch.

Remove KM-6001-A and KM-6173.

Install front exhaust pipe, catalytic

converter and centre muffler with new gaskets and fastening

nuts.

|

|

Engine (thread)

|

Tightening torque

|

|

|

|

|

|

Front exhaust pipe to

|

X 16 SZR, Z 16 SE (M10)

|

35 Nm / 26 lbf. ft.

|

|

Exhaust manifold

|

X 12 XE, Z 12 XE (M10)

|

35 Nm / 26 lbf. ft.

|

|

|

X 14 XE, Z 14 XE, X 16 XEL, Z 16 XE, X 18 XE1, Z 18 XE, X 20

XEV, X 20 DTL (M8)

|

20 Nm / 15 lbf. ft.

|

|

|

X 17 DTL, Y 17 DT (M10x1.25)

|

20 Nm / 15 lbf. ft.

|

|

Centre muffler to

|

|

|

|

rear muffler

|

(M8x1)

|

12 Nm / 9 lbf. ft.

|

Inspect

Inspect

Check level of transmission fluid and correct if necessary

– see operation "Transmission Fluid Level, Check and Correct

(F13/F13+/F17/F17+/F18)".

Install

Install

If present: Install lower engine compartment cover – see

operation "Lower Engine Compartment Cover, Remove and Install" in

group "A".

Adjust Adjust

Adjust transmission shift linkage and tighten clamp bolt –

see operation "Transmission Shift Linkage, Adjust

(F13/F13+/F17/F17+/F18)".

Install

Install

Install battery support – tightening torque 15 Nm / 11

lbf. ft. Install battery.

Inspect

Inspect

Remove blind screw cap from brake fluid reservoir. Bleed

hydraulic clutch actuation – see operation "Hydraulic Clutch

Actuation, Bleed (F13/F13+/F17/F17+/F18/F23)". Top brake fluid

level up to "MAX" mark.

|