|

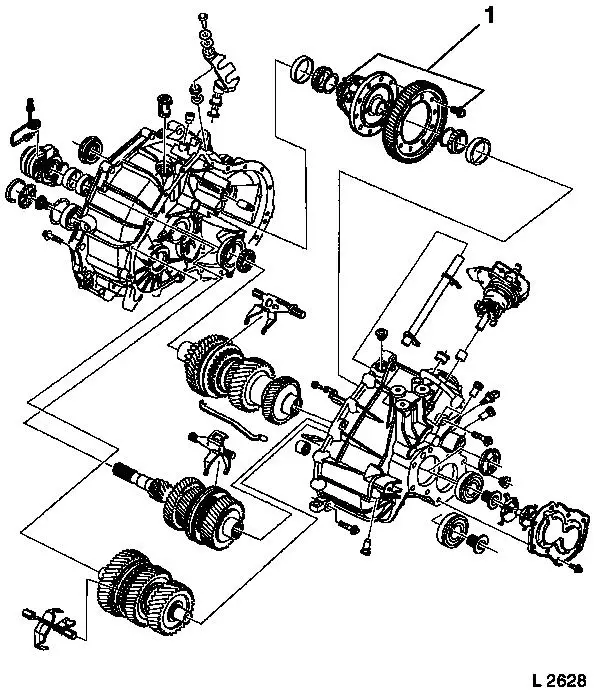

Replace differential gear (F23)

Remove Remove

|

| 2. |

Dismantle transmission

Note: When replacing

the differential, the thrust collar setting must be determined and

adjusted if necessary. The tapered roller bearings of the

differential must be removed to do this

| 1. |

Differential with differential ring gear |

|

|

|

Important: For determination of

the shims for the bearing pre-tension, the determination on the

transmission side for adjustment of the pressure comb is always

given priority.

|

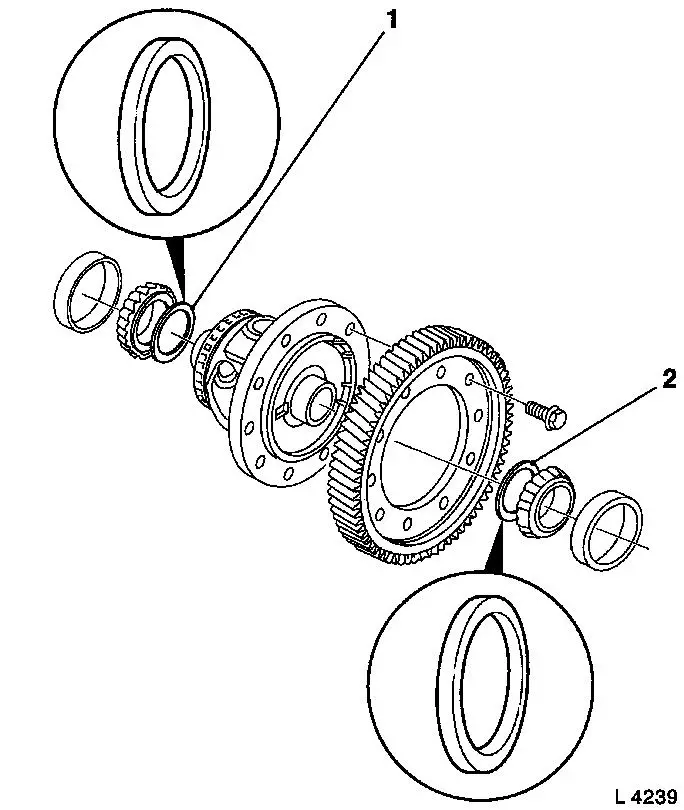

| 3. |

Check adjustment of thrust collar

| • |

Measure the size of the shim on the transmission housing side

(2)

Note: Is used for

adjusting the thrust collar.

|

| • |

Measure size of the shim on the clutch housing side (1)

Note: Is used for

adjusting the bearing pre-tensioning of the tapered roller bearing

of the differential

|

|

|

|

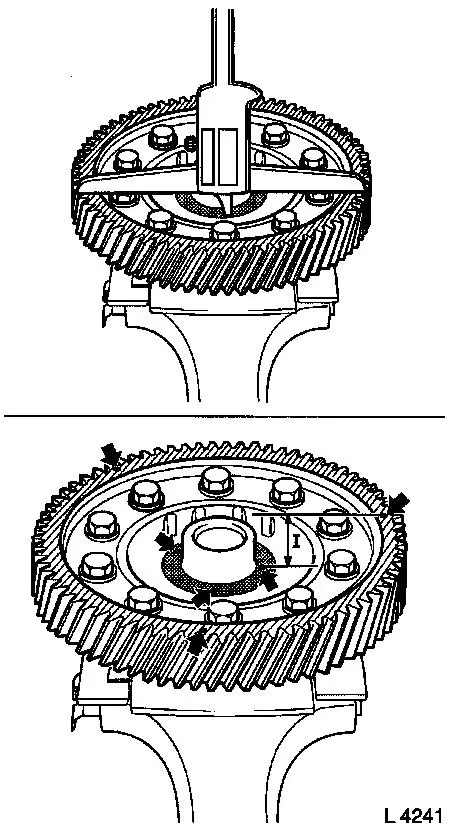

| 4. |

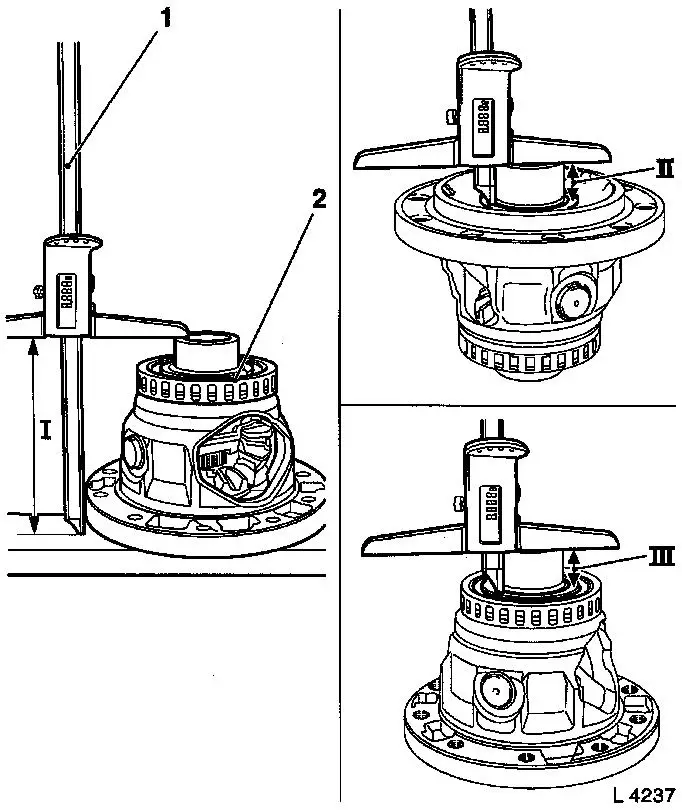

Measurement (I) Distance between the height of the ring gear

and the seat of the tapered roller bearing, measure shim on

transmission housing side

Note: With a standard

commercial digital depth gauge with a measuring range of at least

250 mm and graduations of 0.01 mm, determine the measurement (I),

distance between the height of the ring gear and the seat of the

tapered roller bearing for the differential on the housing

side.

| • |

Undertake measurement at three measuring points (arrows) evenly

distributed around the ring gear and differential

|

| • |

Add up measured values and divide by the number of

measurements

Note: This method of

calculation is illustrated in the table below.

|

|

|

| 5. |

Measured values

Note: The purpose of

the following tables is to explain the pressure comb adjustment

using an example calculation.

The measured values in the left hand table serve as an example of

the calculation used for evaluating the measurement.

You can enter your measured results in the right hand table (as a

print-out) to make the evaluation easier.

|

Example:

|

|

|

|

Measurement:

|

|

Your values

|

|

1st measurement

|

|

15.02 mm

|

|

1st measurement

|

|

|

|

2nd measurement

|

+

|

15.06 mm

|

|

2nd measurement

|

+

|

|

|

3rd measurement

|

+

|

15.05 mm

|

|

3rd measurement

|

+

|

|

|

Total value

|

=

|

45.13 mm

|

|

Total value

|

=

|

|

|

Mean value

|

:3 =

|

15.04 mm

|

|

Mean value

|

:3 =

|

|

Note: This measurement

is undertaken on the old differential with the old ring gear, then

the new differential is measured, this can be with the new or old

ring gear depending on whether the ring gear also has to be

replaced. Ring Gear, Remove/Install

If a value deviates by more than 0.08 mm from the other values of

this measurement, the measurement must be repeated as a measurement

error has occurred.

|

| 6. |

Determine difference measurement

|

Table for example of calculation of difference

measurement:

|

|

Mean value, new shaft

|

|

15.16 mm

|

|

Mean value, old shaft

|

-

|

15.04 mm

|

|

± Difference

|

=

|

+ 0.12 mm

|

|

Table for your difference measurement

calculation:

|

|

Mean value, new shaft

|

|

|

|

Mean value, old shaft

|

-

|

|

|

± Difference

|

=

|

|

Note: The total

thickness of the two shims remains constant because this produces

the bearing pre-tensioning for the tapered roller bearings.

| • |

Deduct mean value for the old differential from the mean value

for the new differential

Note: If the difference

measurement between the old and the new differential is more than

(+0.02/-0.06) mm, the thrust collar must be adjusted.

|

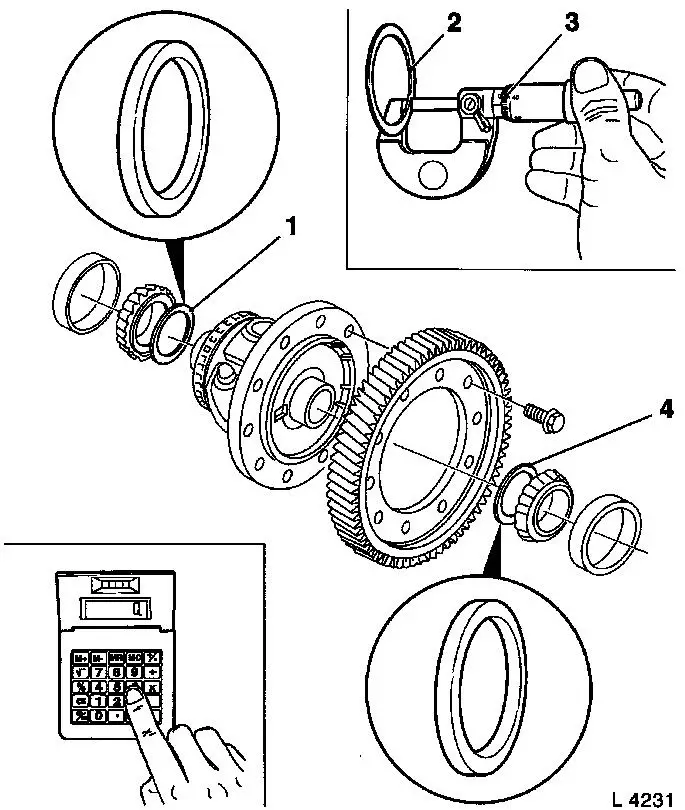

| • |

If the difference measurement is positive (+), the shim (on the

transmission housing side) (4) must be selected so that it is the

same measurement thicker

|

| • |

If the difference measurement is negative (-) (on the

transmission housing side) (4) the shim must be selected so that it

is the same measurement thinner

|

| • |

if the shim (on the transmission housing side) (4) is thicker,

the shim (on the clutch housing side) (1) must be selected so that

it is the same measurement thinner

|

| • |

if the shim (on the transmission housing side) (4) is thinner,

the shim (on the clutch housing side) (1) must be selected so that

it is the same measurement thicker

|

|

|

| 7. |

Determine actual measurement of the shims (2)

|

Difference measurement

|

Shim (transmission housing side)

|

Shim (clutch housing side)

|

|

- 0.25 mm

|

old

|

0.90 mm

|

new

|

0.65 mm

|

old

|

0.75 mm

|

new

|

1.00 mm

|

|

+ 0.20 mm

|

old

|

0.90 mm

|

new

|

1.10 mm

|

old

|

0.75 mm

|

new

|

0.55 mm

|

|

+ 0.13 mm

|

old

|

0.90 mm

|

new

|

1.05 mm

|

old

|

0.75 mm

|

new

|

0.60 mm

|

|

+ 0.12 mm

|

old

|

0.90 mm

|

new

|

1.00 mm

|

old

|

0.75 mm

|

new

|

0.65 mm

|

Note: During adjustment,

the shims must be selected so that the smallest possible tolerance

is achieved.

Used shims can be re-used for subsequent adjustment operations,

provided that they have not been damaged.

The shim (clutch housing side) is only altered in the subsequent

adjustment of the bearing pretension for the differential

regardless of the shim (transmission housing side).

Note: Appropriate shims

can be ordered via the "Service" Department.

| • |

The actual measurement of the shims is determined using a

micrometer (3) since the shims are not labelled.

|

|

|

|

Important: The next measurement

is carried out on the old and new differential (2) without

differential tapered roller bearing and without ring gear. However,

the measurement for the shim (transmission housing side) that has

already been determined must also be taken into account; this

measurement must be given highest priority for adjustment

operations on the differential and must not be altered in the

subsequent adjustment.

|

| 8. |

Measure differential

|

Example:

|

|

|

|

Measurement:

|

Your values

|

|

Measurement I

|

|

210.25 mm

|

|

Measurement I

|

|

|

|

Measurement II

|

-

|

18.25 mm

|

|

Measurement II

|

-

|

|

|

Measurement III

|

-

|

18.30 mm

|

|

Measurement III

|

-

|

|

|

Measurement IV

|

=

|

173.70 mm

|

|

Measurement IV

|

=

|

|

Note: Measure with a

standard commercial digital depth gauge (1) with a measuring range

of at least 250 mm and graduations of 0.01 mm

| • |

Determine measurement of differential (I), (II) and (III)

3x

|

| • |

Deduct measurement I from measurement II and III

Note: This method of

calculation is illustrated in the table below.

Measurement IV corresponds to the distance between the seats of the

tapered roller bearings of the differential

|

|

|

| 9. |

Measure old differential

- Undertake measurement at three measuring points evenly

distributed over the differential

- Add calculated values, measurement IV, and divide by the number

of measurements

Note: This method of

calculation is illustrated in the table below.

|

Example:

|

|

|

|

|

Measurement:

|

|

Your values

|

|

1st measurement

|

Measurement IV

|

|

90.02 mm

|

|

1st measurement

|

Measurement IV

|

|

|

|

2nd measurement

|

Measurement IV

|

+

|

90.06 mm

|

|

2nd measurement

|

Measurement IV

|

+

|

|

|

3rd measurement

|

Measurement VI

|

+

|

90.05 mm

|

|

3rd measurement

|

Measurement IV

|

+

|

|

|

Total value

|

|

=

|

270.13 mm

|

|

Total value

|

|

=

|

|

|

Mean value

|

|

:3 =

|

90.04 mm

|

|

Mean value

|

|

:3 =

|

|

Note: This measurement

is performed in the same way on the new differential. If the height

difference between the old and the new differential is greater than

± 0.04 mm, the differential bearing pre-tension must be

adjusted. If the height difference is less than ± 0.04 mm,

the adjustment for the differential bearing pre-tension is

retained. Only the measurement of the shim (clutch housing side) is

adapted to the measurement of the shim (transmission housing side).

This is illustrated in the following table.

|

Shim (transmission housing side) old

|

Shim (clutch housing side) old

|

|

Shim (transmission housing side) new

|

Shim (clutch housing side) new

|

|

0.90 mm

|

1.10 mm

|

|

1.00 mm

|

1.00 mm

|

|

1.25 mm

|

0.75 mm

|

|

1.10 mm

|

0.90 mm

|

Note: The total

thickness of the two shims remains the same as long as the height

of the differential (measurement IV) does not change or the

deviation remains less than ± 0.04 mm. The determination of

the shims for the adjustment of the differential bearing pretension

is described in the table below.

The total measurement of the shim + height of differential

(measurement IV) = remains constant ± 0.04 mm, for new and

old differential. This means that the differential and shim

assembly for the new differential must have the same measurement as

that of the old differential. The adjustment has then been

performed correctly.

The measurement determined previously for the shim (on the

transmission housing side) may not be changed.

| • |

If measurement IV on the new differential is greater than

measurement IV on the old differential, the shim (clutch housing

side) is selected thinner by the difference in measurement IV

|

| • |

If the new differential is shorter than the old differential,

the shim (clutch housing side) is selected thicker by the

difference in the measurement (IV)

|

|

Install

Install

| 10. |

A few examples for using the shims are listed in the table

below.

|

Measurement IV (old)

|

Shim (clutch housing side) old

|

Measurement IV (new)

|

Shim (clutch housing side) new

|

|

90.10 mm

|

0.75 mm

|

90.03 mm

|

0.80 mm

|

|

90.07 mm

|

0.85 mm

|

90.15 mm

|

0.75 mm

|

|

90.21 mm

|

0.90 mm

|

90.08 mm

|

1.05 mm

|

|

| 11. |

The smallest possible tolerance is desirable for the

adjustment. In doing so, the shim (transmission housing side) must

not altered, since the pressure collar adjustment has already been

made.

|

|

| 12. |

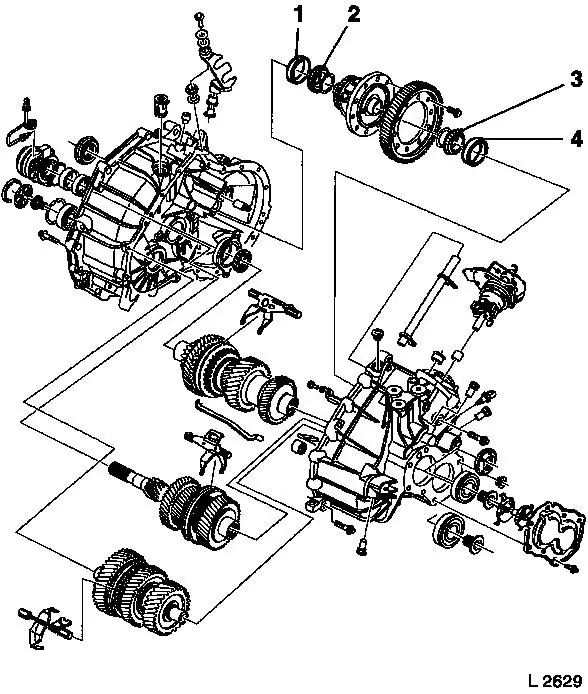

Overview

Note: If the

differential is to be replaced re-using the run-in inner tapered

roller bearing races for the differential (2 and 3) these must be

changed over

If using new inner tapered roller bearing races, the outer tapered

roller bearing races of the differential (1 and 4) must also be

replaced

|

| 13. |

Attach differential ring gear

|

|

| 14. |

Assemble transmission

|

|