Corsa C

|

Standard Corrosion Protection Measures - Models F 08, F 08 & W5L, F 68, F 25, F 06 General In recent years, the subject of corrosion protection has been forcefully pushed into the foreground as a result of increasingly corrosive environmental pollution. The customer expects that his vehicle has received high quality anticorrosive protection with enduring effectiveness during series production. For these reasons, improvements are continually being introduced into production:

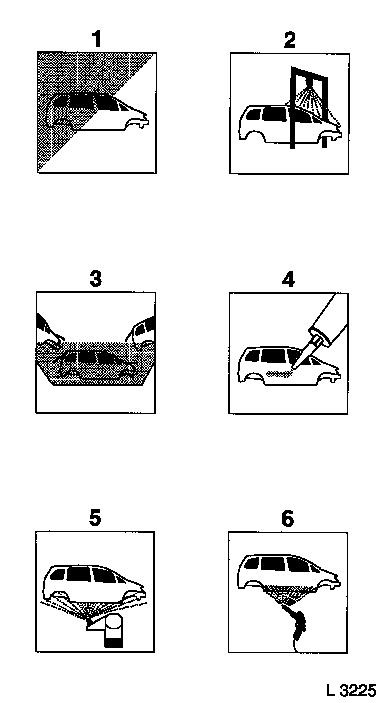

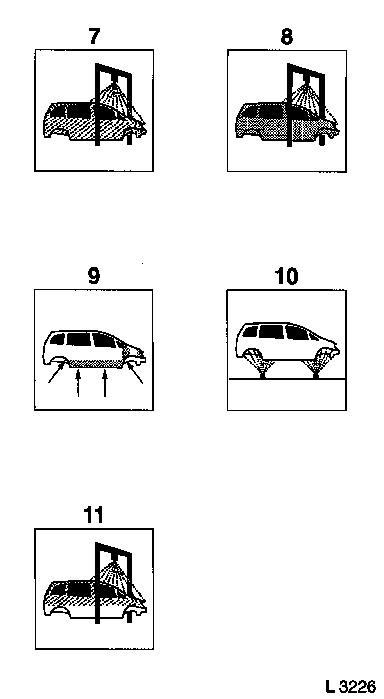

In this section, the typical corrosion protection steps in series production will be explained using a flowchart and subsequent description of the individual steps. The details of the individual steps may differ depending on production plant. Note: All of the measures for corrosion protection discussed in the operations can be understood with reference to the descriptions in this section. Flowchart for Corrosion Protection Steps

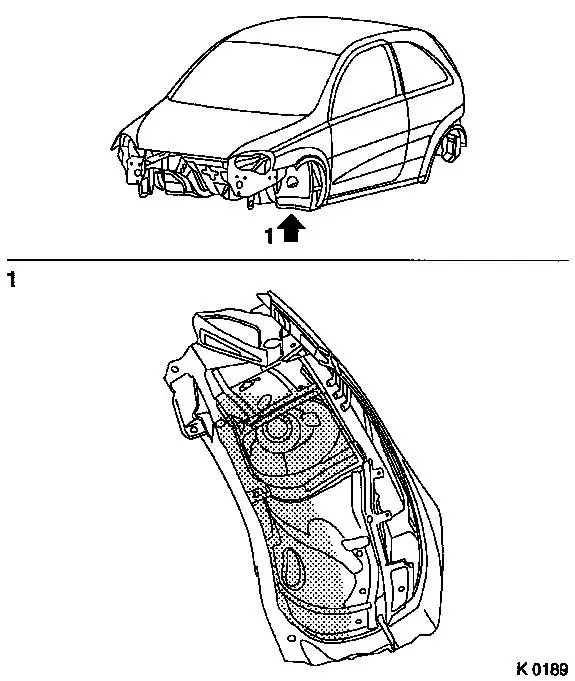

Body shell

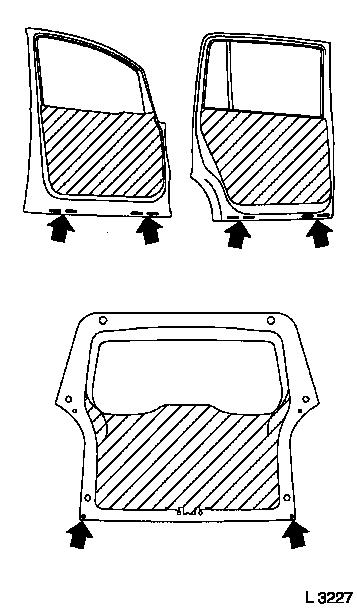

Example: The good drainage of dirt and water is assisted by water drain holes in door shells. Spray dip phosphatisation Spray dip phosphatisation with the preceding and succeeding cleaning and rinsing processes is the foundation for the build-up of the paint.

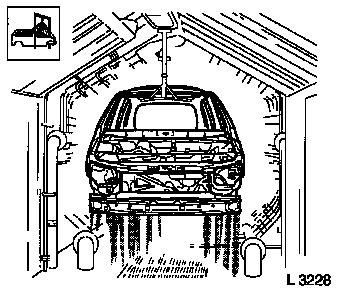

Spray dip phosphatisation is performed by treatment with a phosphate solution. This causes a crystal layer to form which neutralises points of different potential. Cataphoretic Dip Priming (CDP) CDP is the next corrosion protection step in series production.

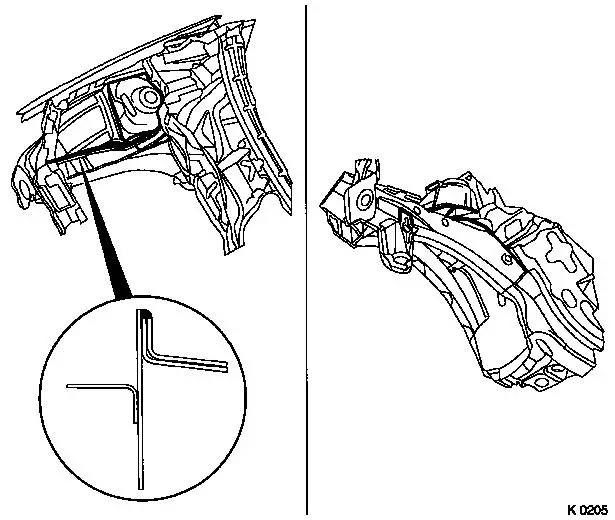

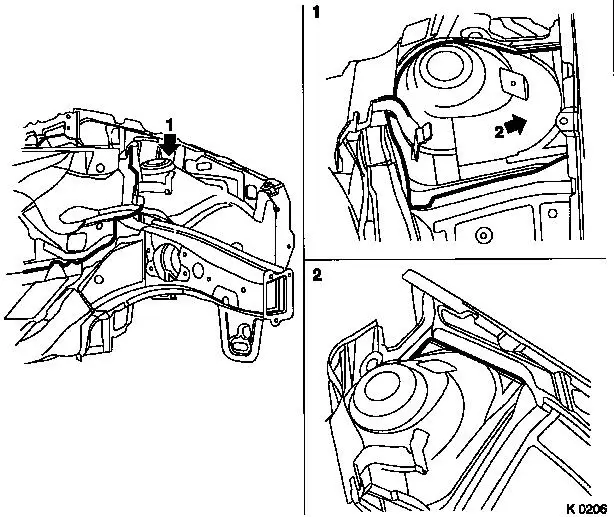

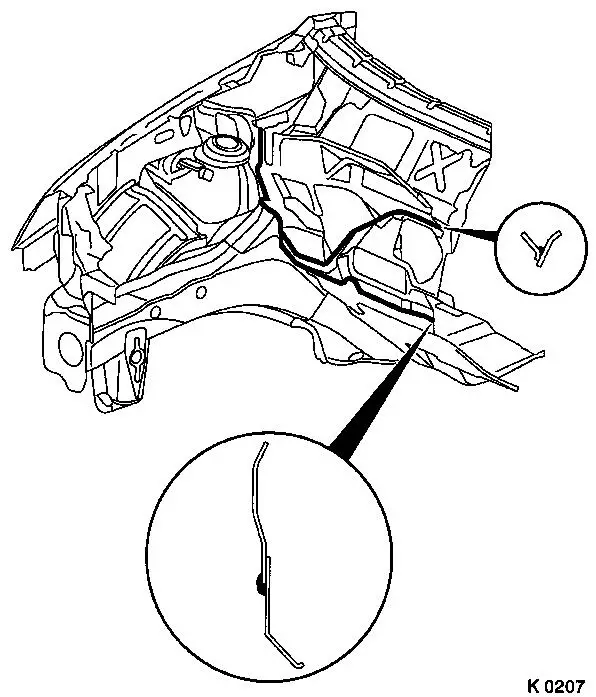

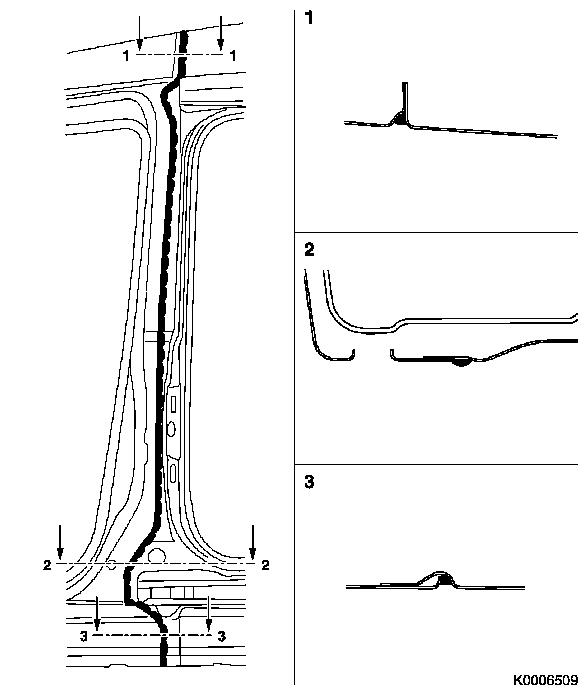

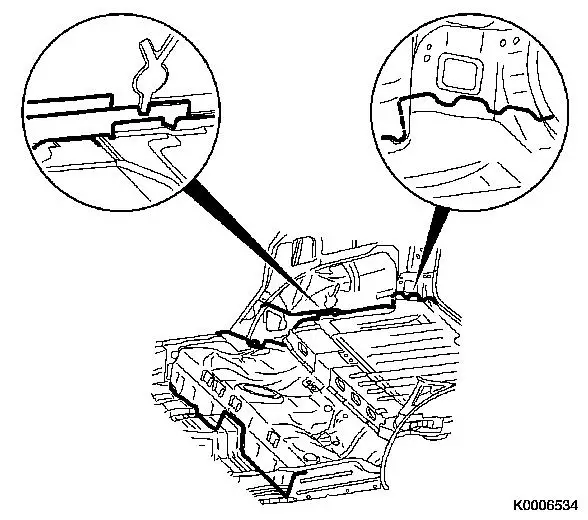

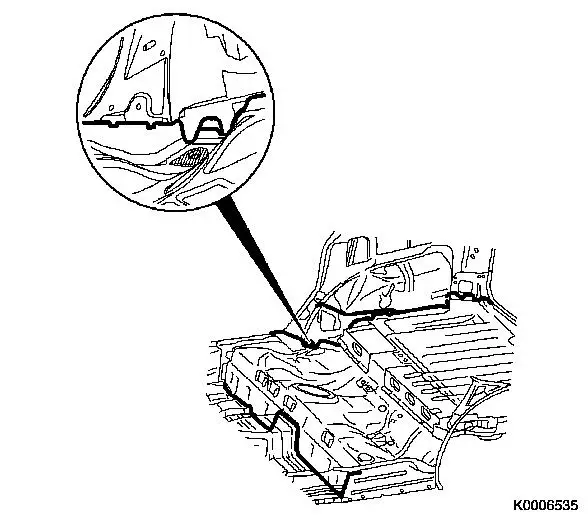

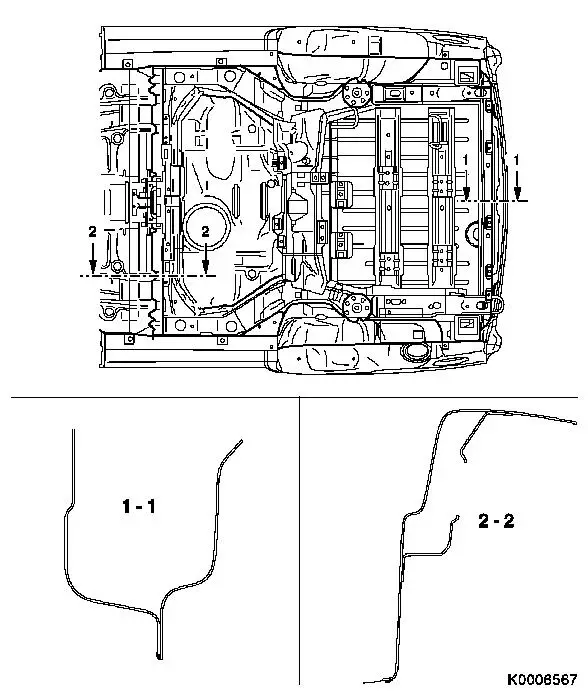

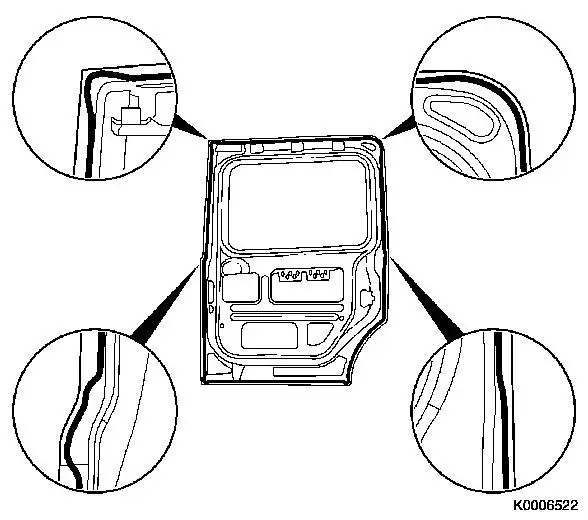

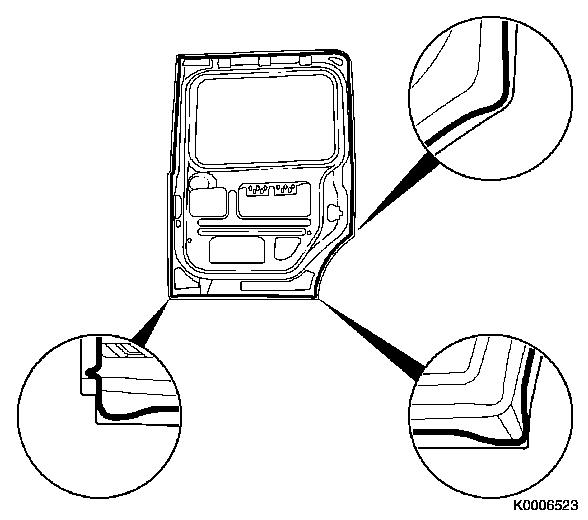

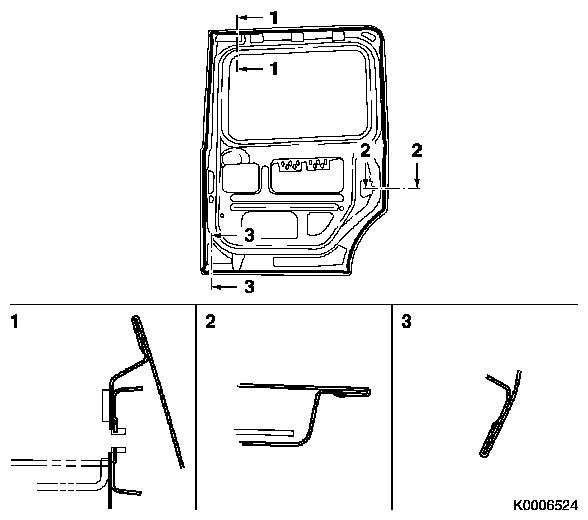

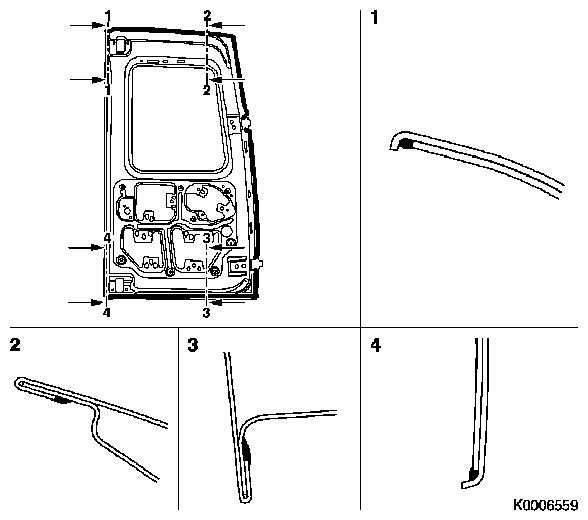

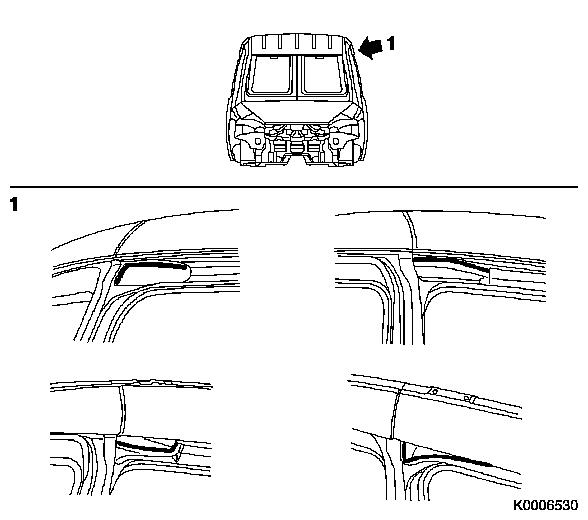

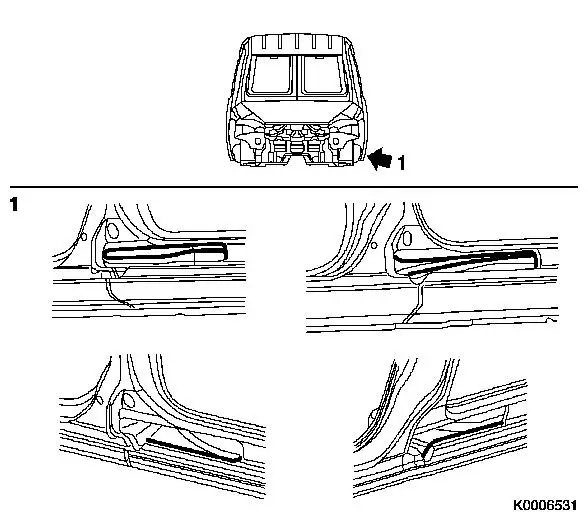

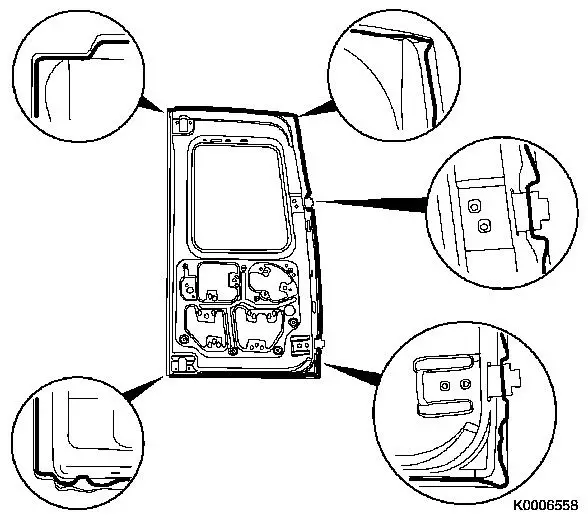

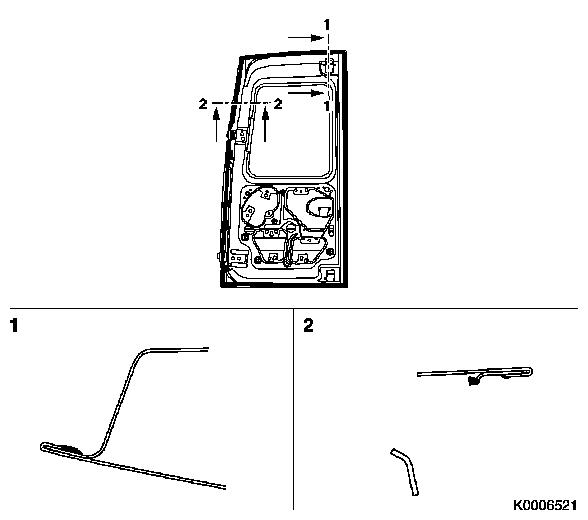

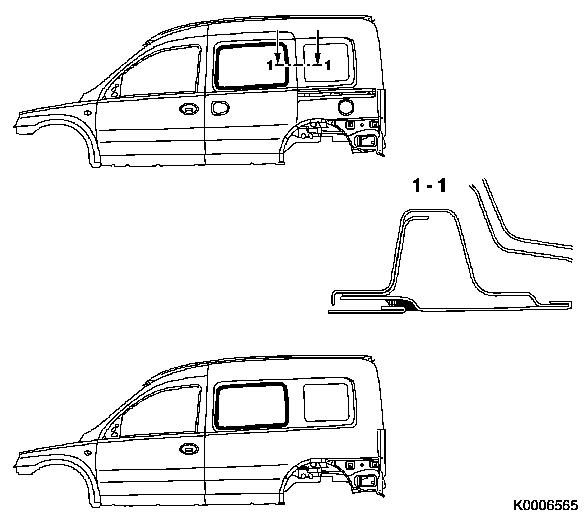

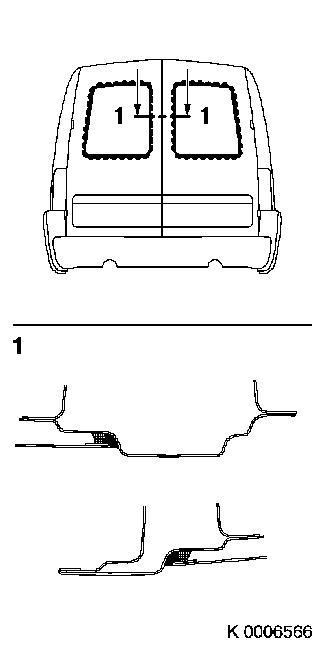

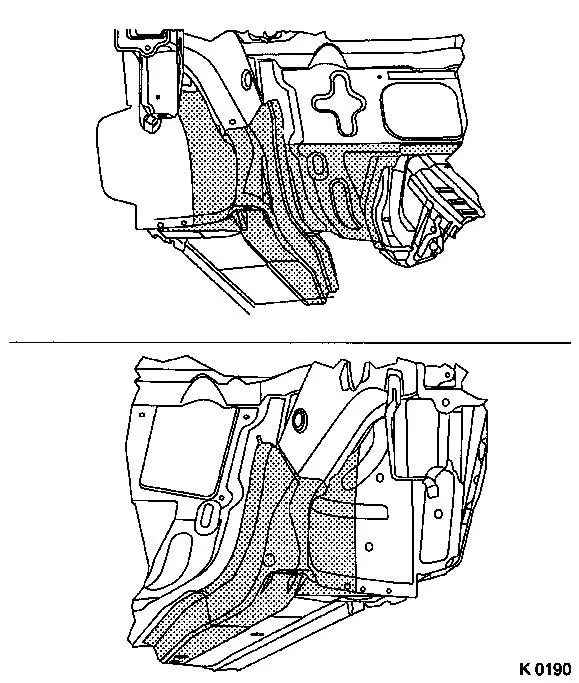

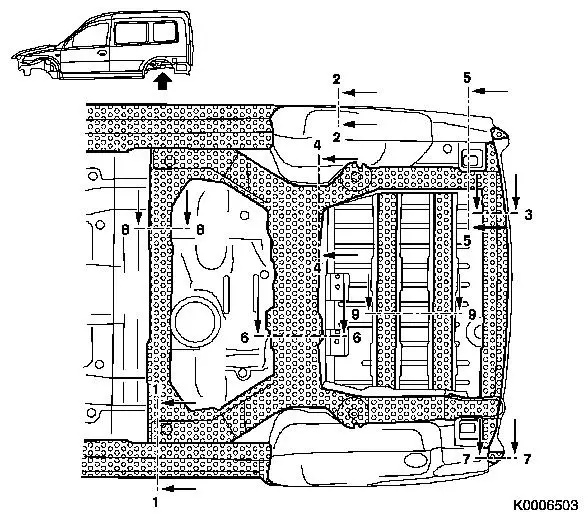

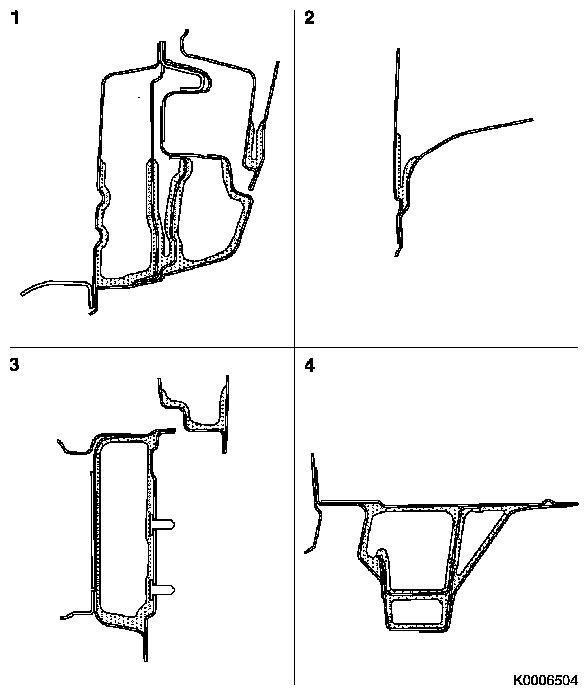

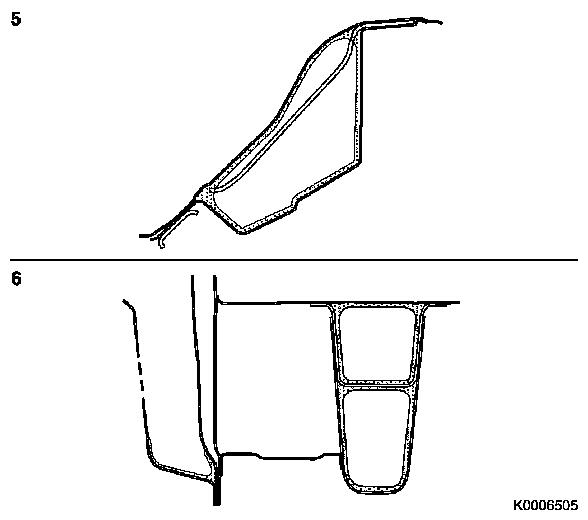

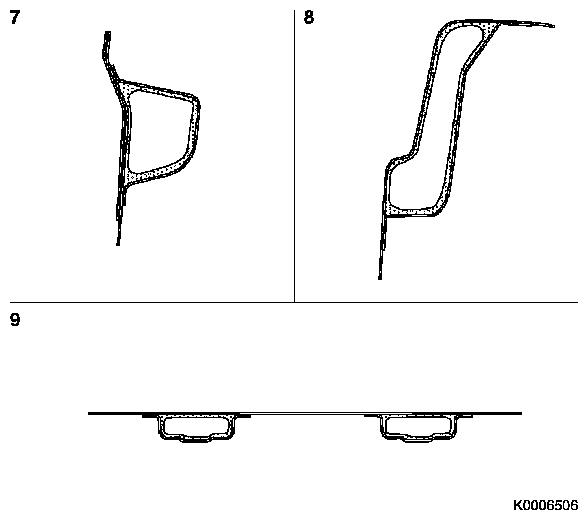

The body (cathode) passes through a dip tank with water-soluble paint (anode). The positively charged particles of paint migrate to the body under the influence of the voltage and form a layer of paint. The thickness of the layer is determined by the amount of electricity, the length of coating and the temperature of the paint bath. Seam seal Heat-curing and solvent-free seam seals are applied to flanged seams and folds and smoothed. Models F 08, F 08 & W5L, F 68, F 25, F 06

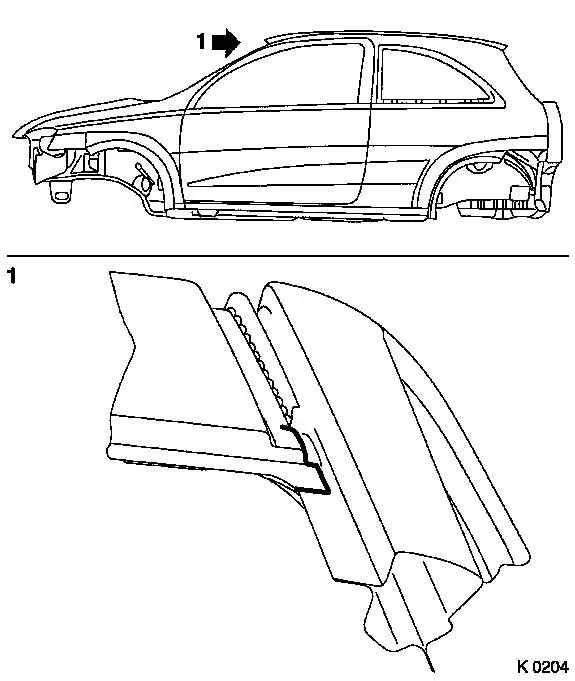

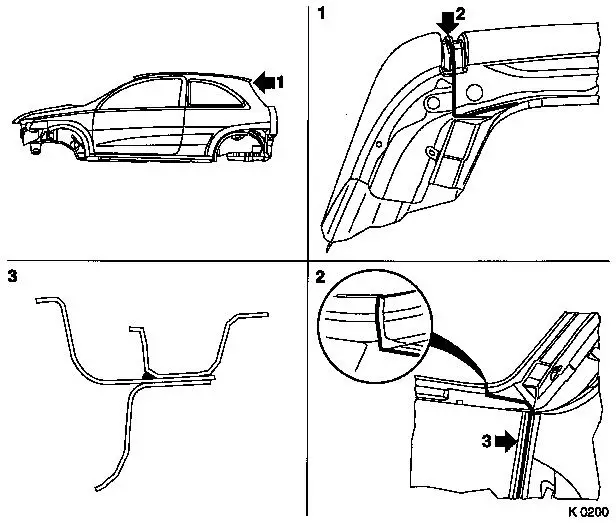

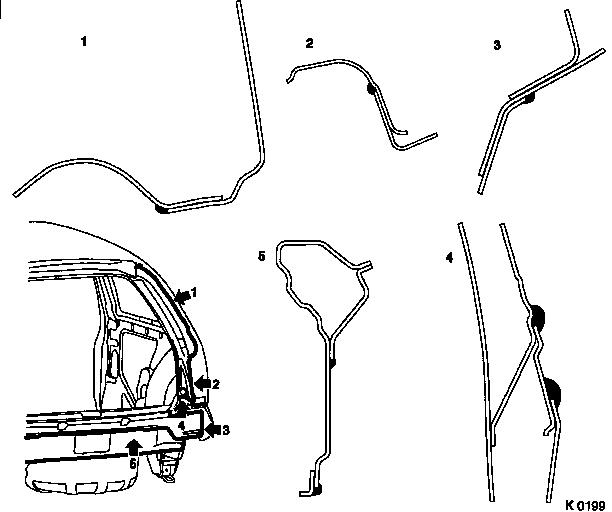

Model F 08, F 08 & W5L, F 68

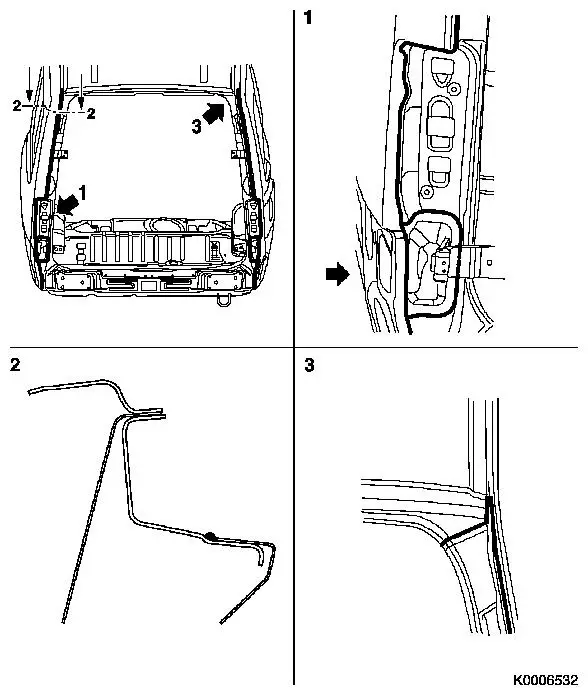

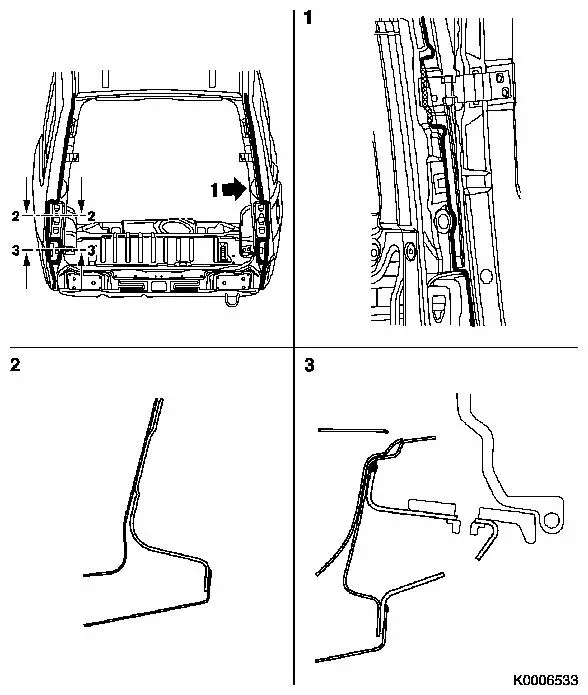

Models F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

Models F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

Models F 08, F 08 & W5L, F 68, F 25, F 06

Models F 25, F 06

Models F 08, F 08 & W5L, F 25, F 06

Model F 68

Models F 25, F 06

Models F 08, F 08 & W5L, F 68, F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

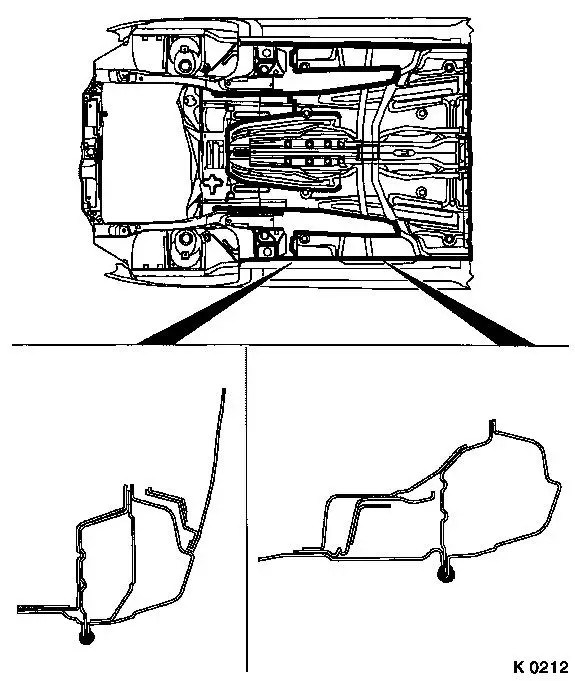

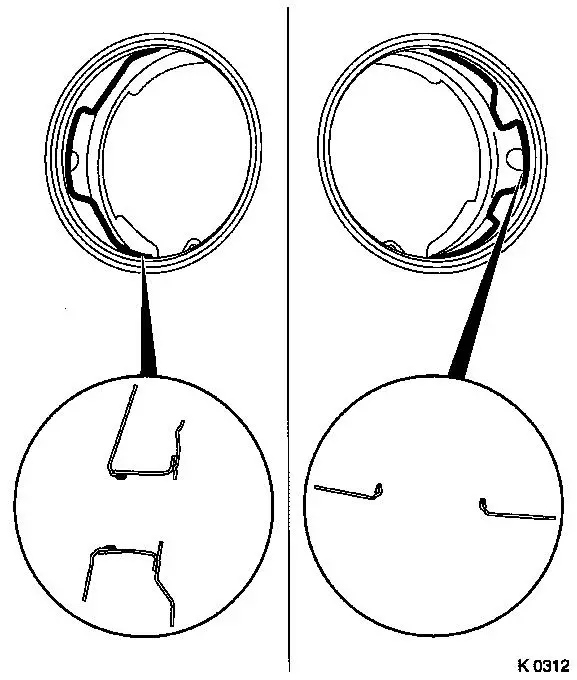

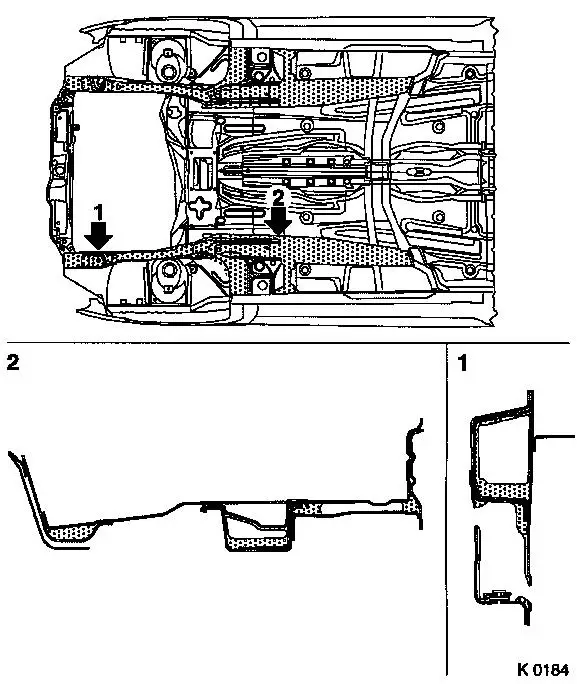

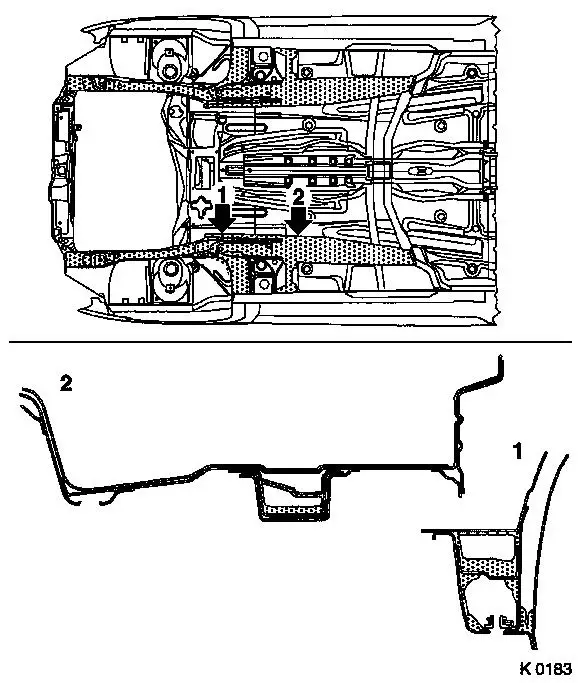

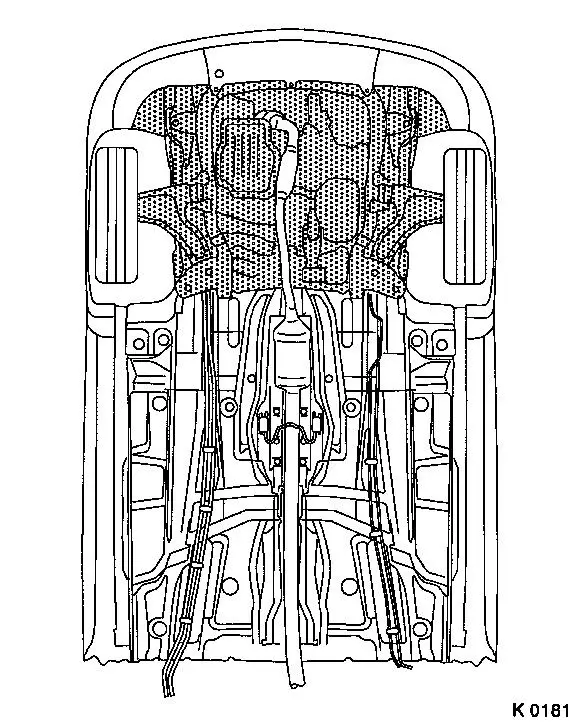

PVC underseal

Models F 08, F 08 & W5L, F 68, F 25, F 06

Models F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

Models F 08, F 08 & W5L, F 68, F 25, F 06

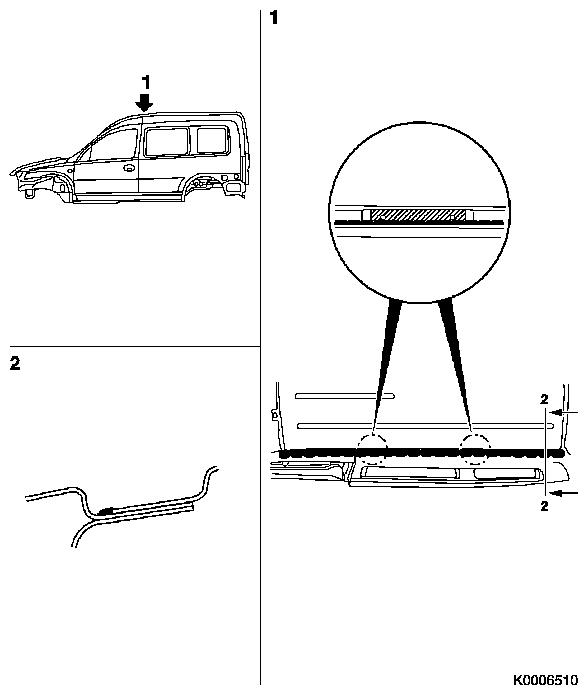

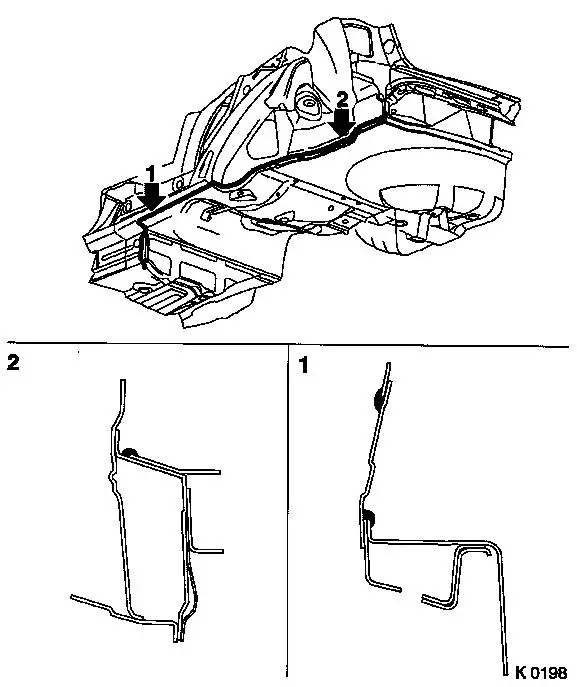

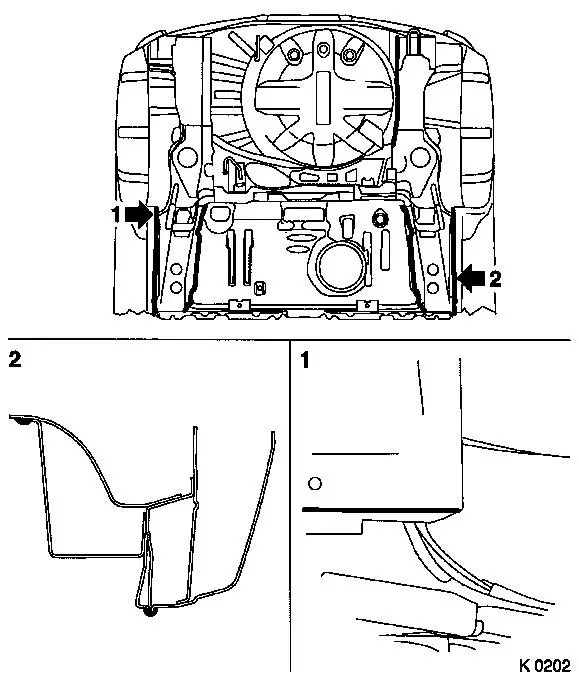

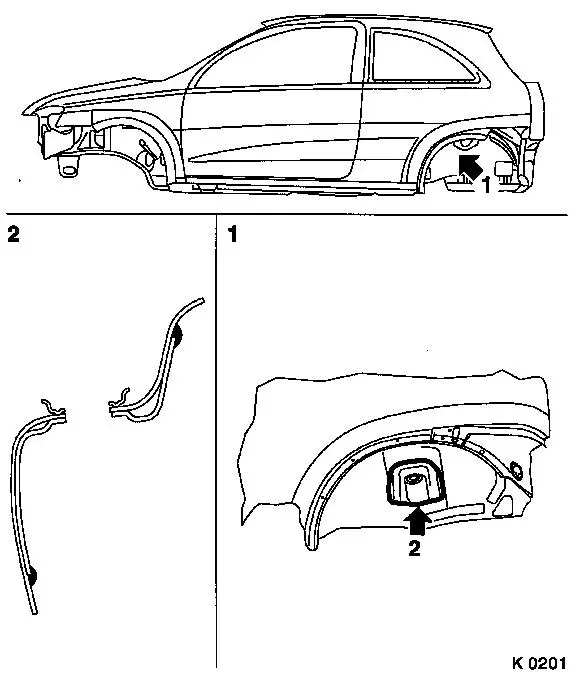

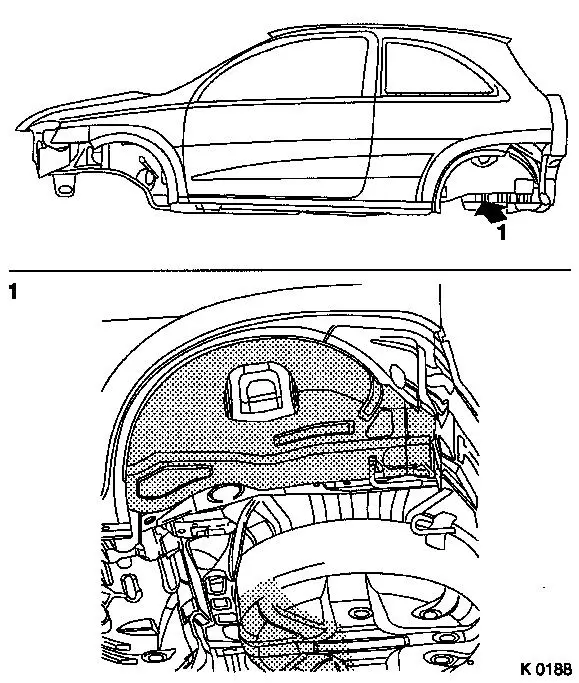

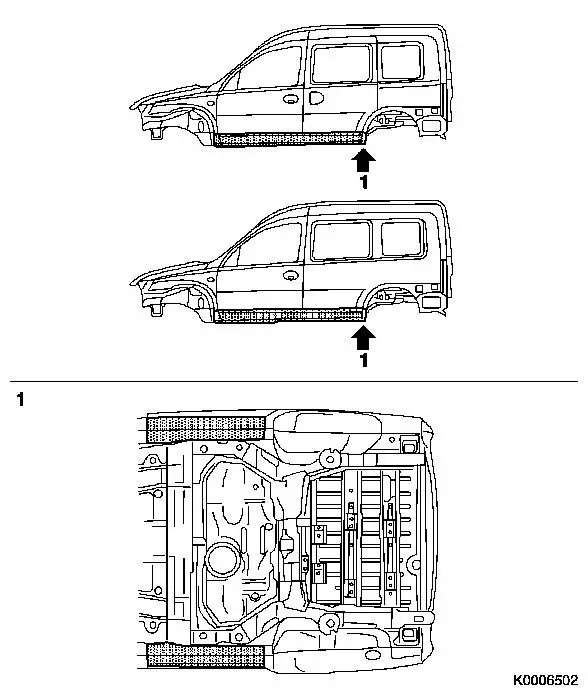

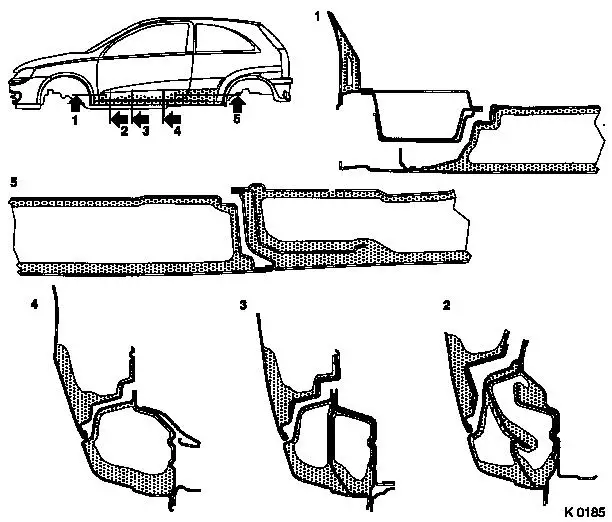

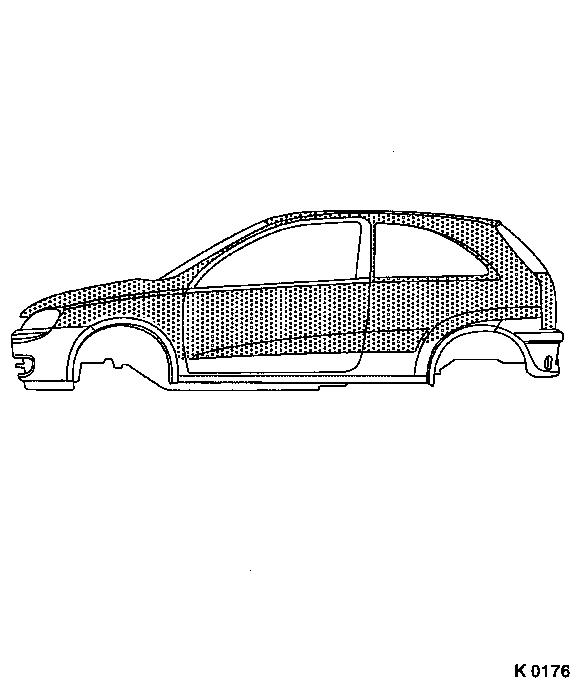

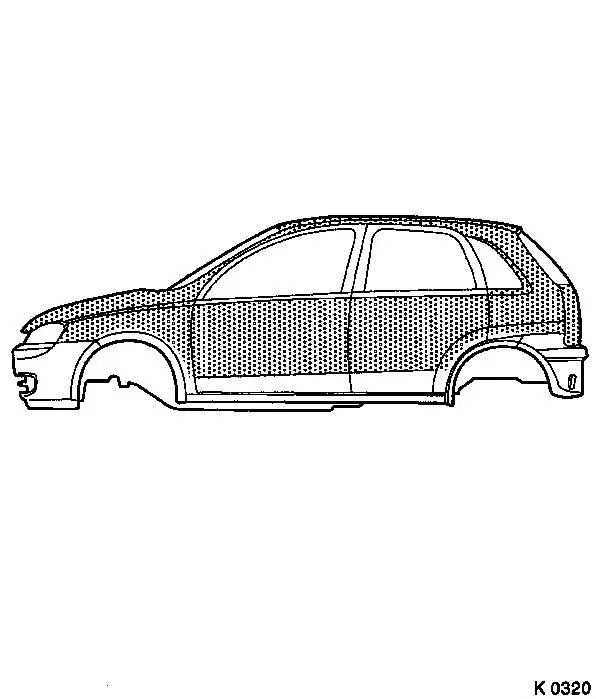

PVC sill protection Models F 08, F 08 & W5L, F 68, F 25, F 06 The PVC sill protection cures in heat and is solvent-free and is sprayed in a sophisticated, "Visible Edge" automatic spray process. With regard to corrosion protection, PVC sill protection has the following advantages:

A straight and clean visible edge without any transition is achieved in the spraying operation using a special application procedure Models F 25, F 06

Primer The water-soluble primer is applied with an electrostatic rotary atomiser unit. The following sequence applies:

Top coat With its blocking effect to the diffusion of water and oxygen, the top coat is the final layer of the paint build-up. The following sequence applies:

Two different top coat systems may be used:

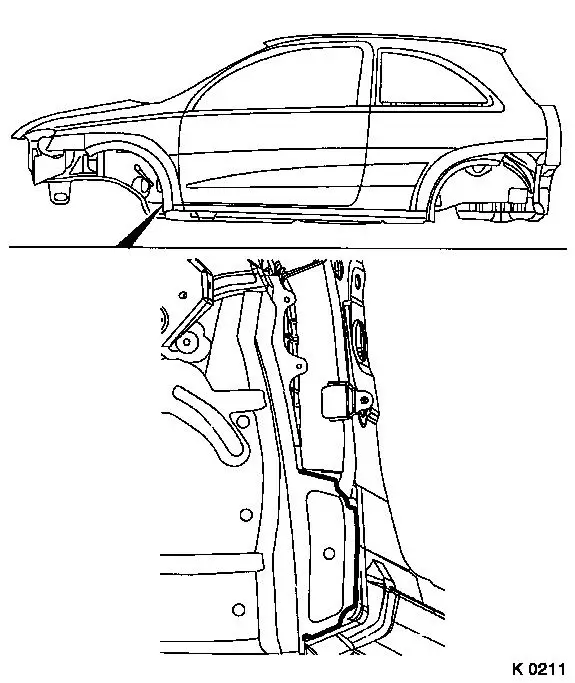

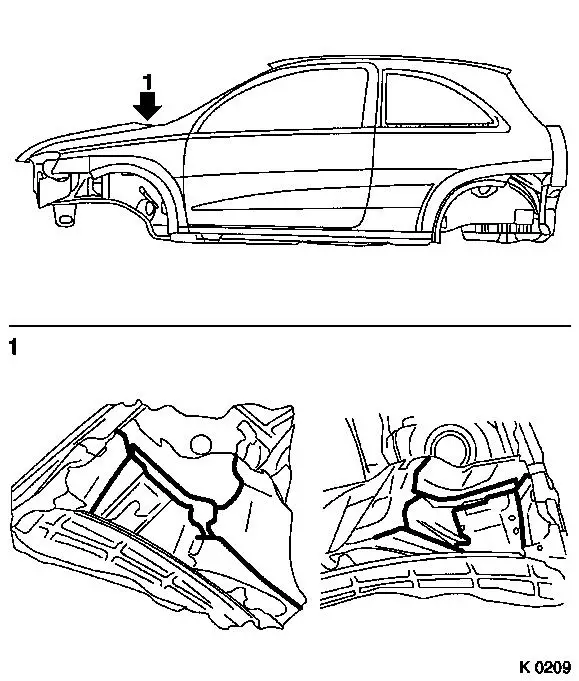

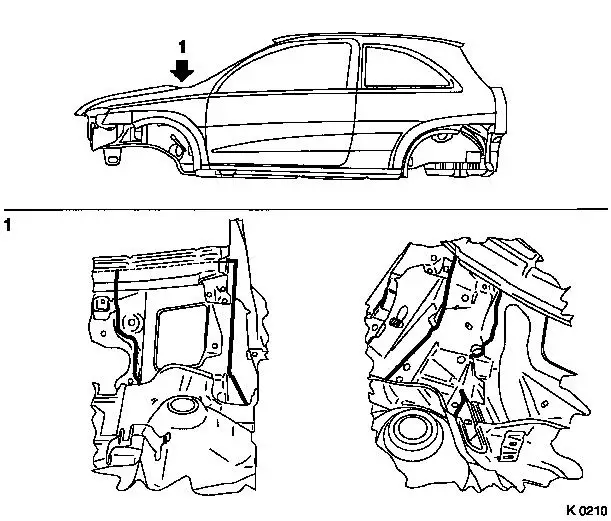

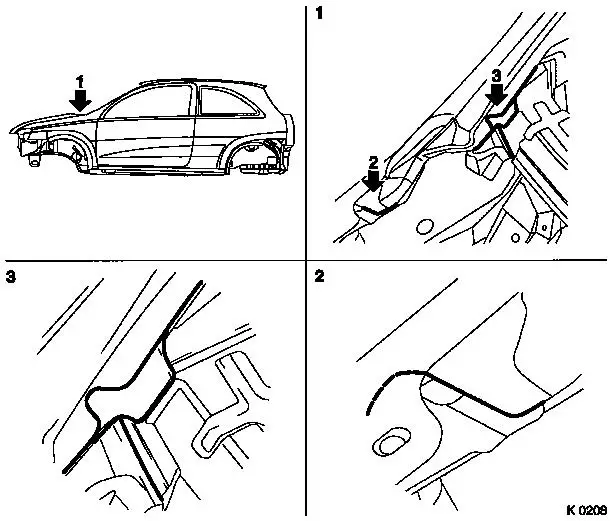

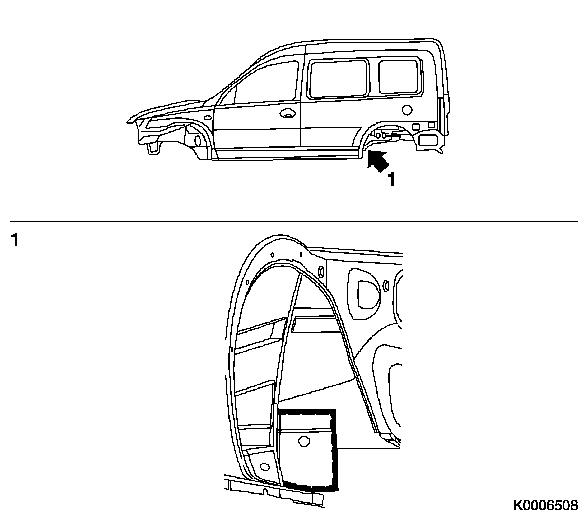

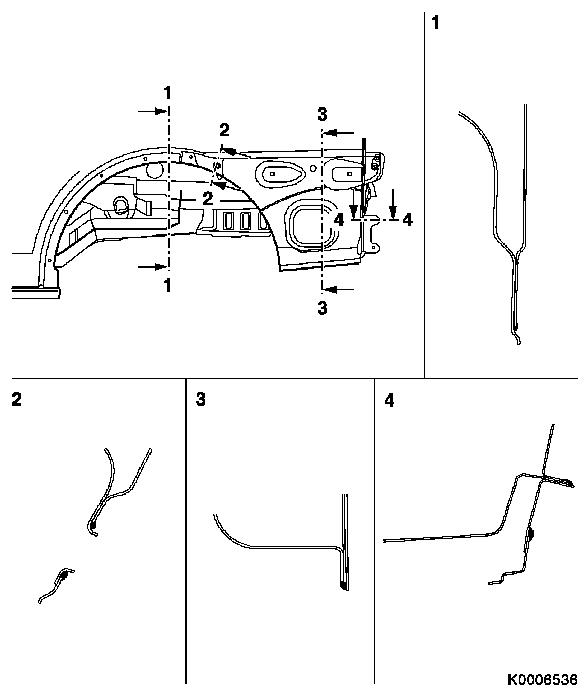

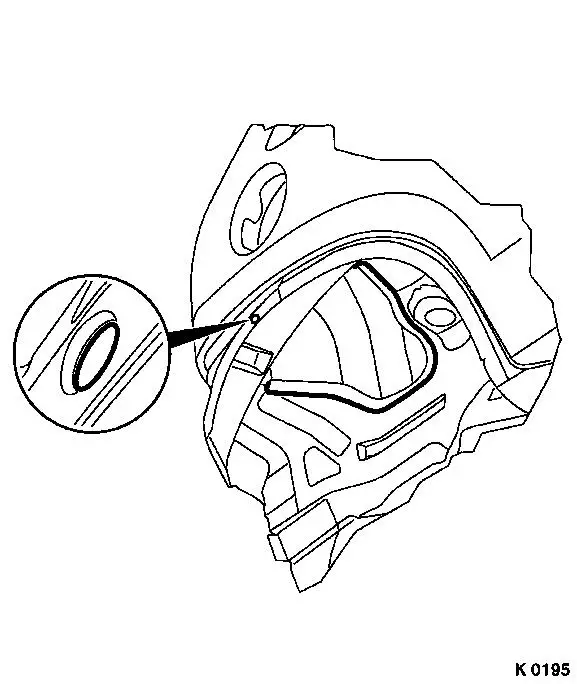

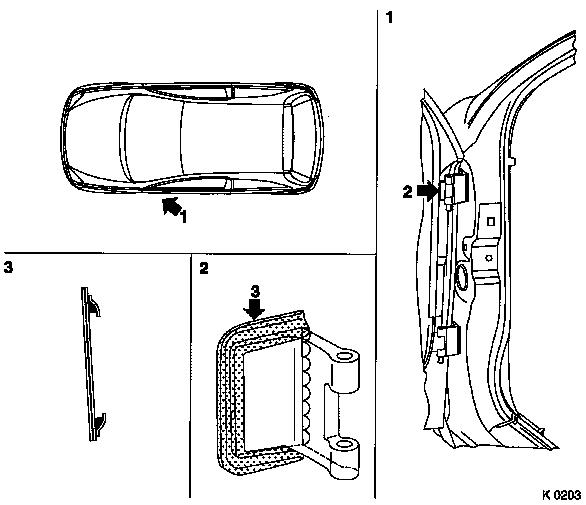

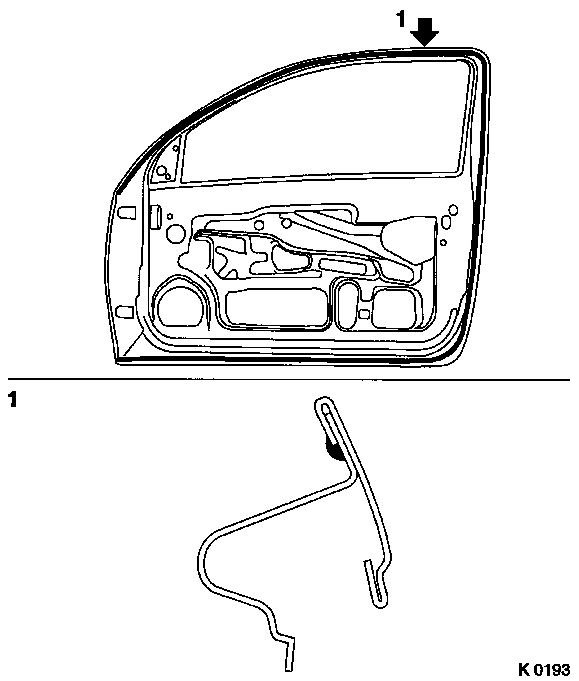

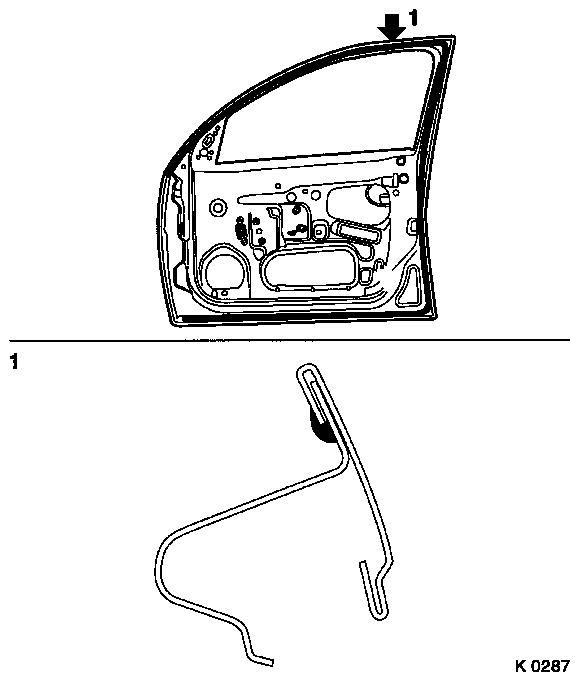

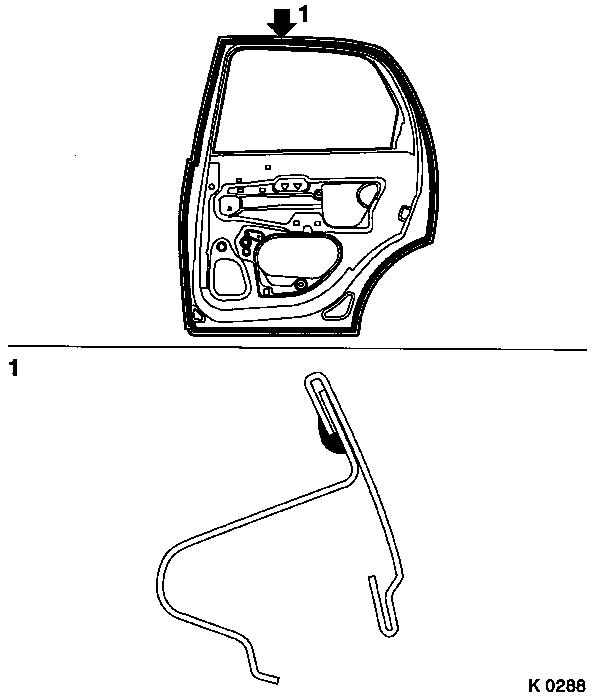

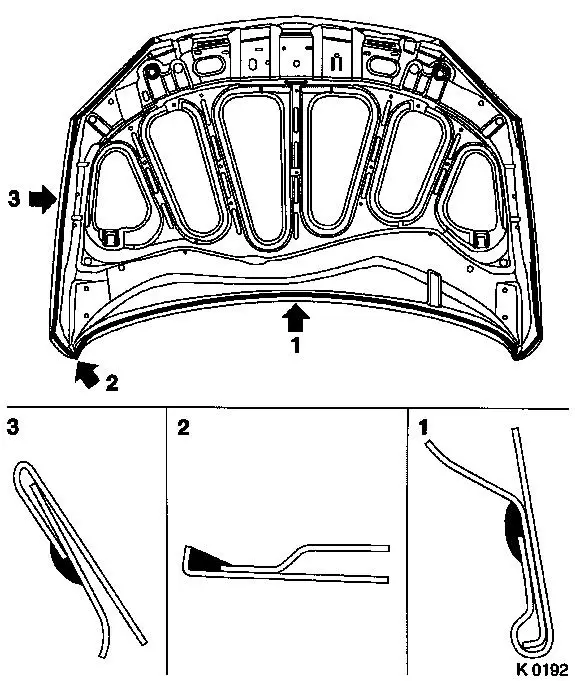

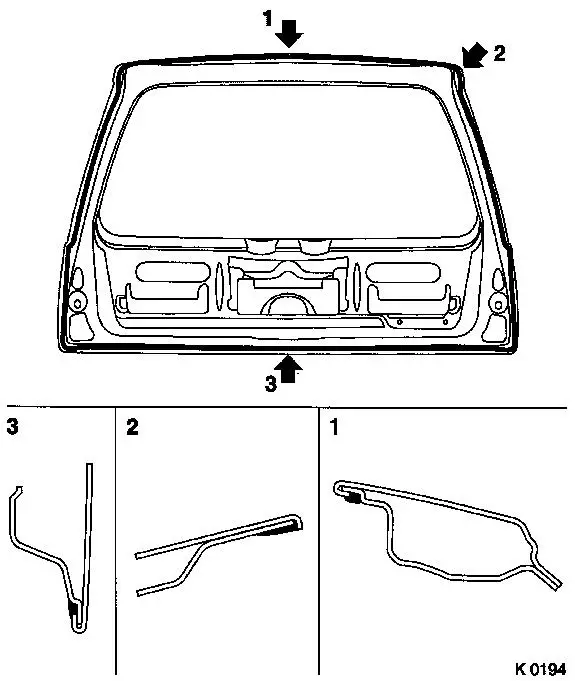

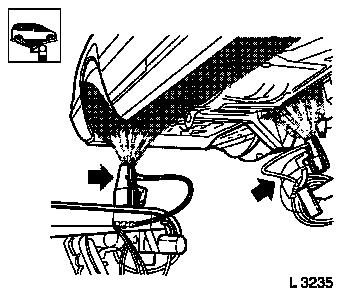

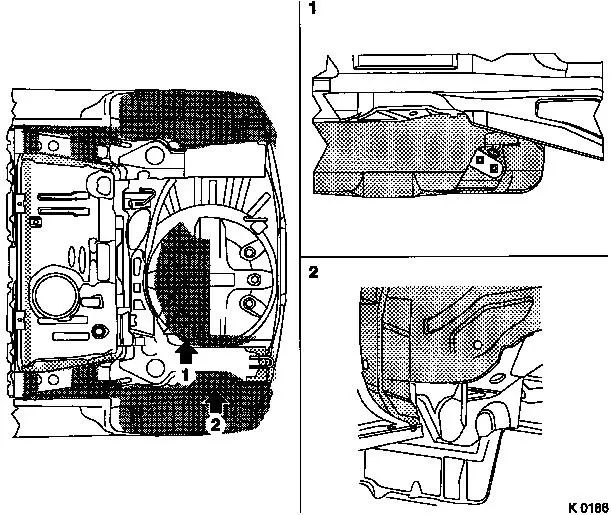

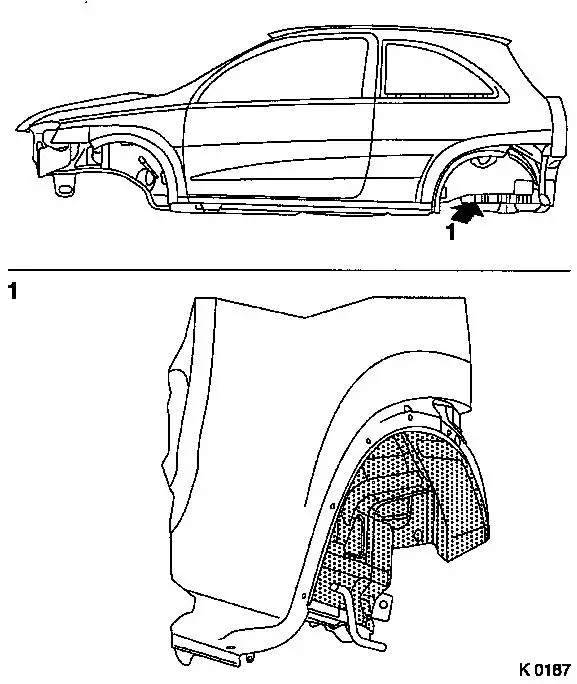

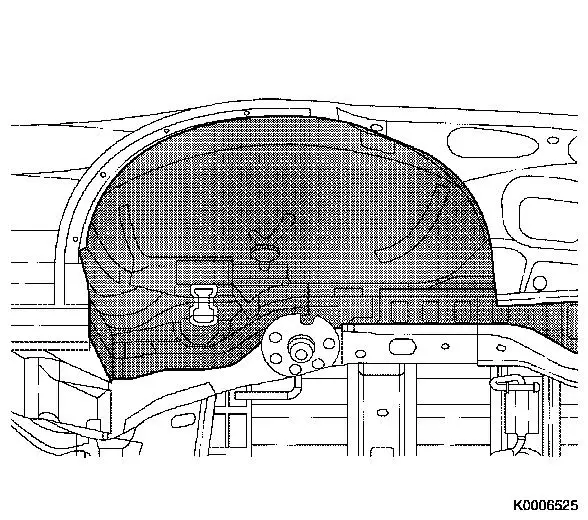

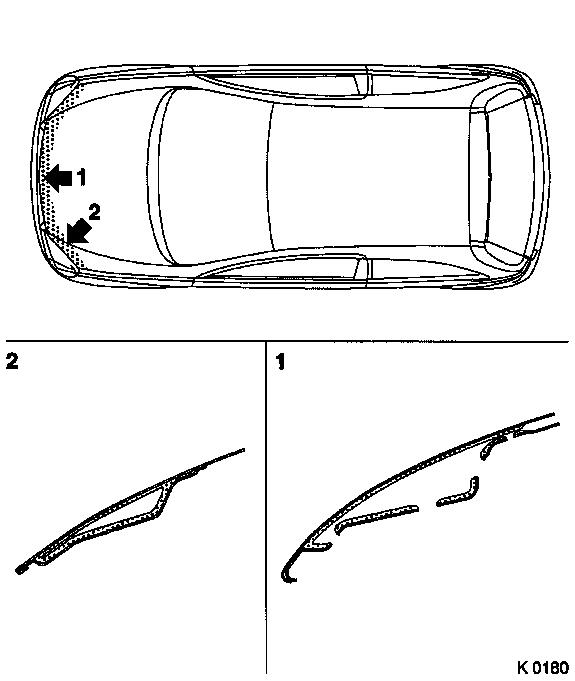

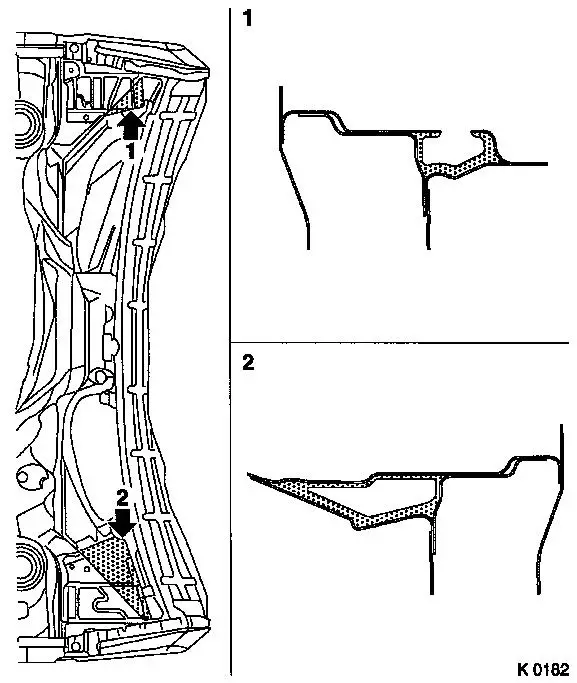

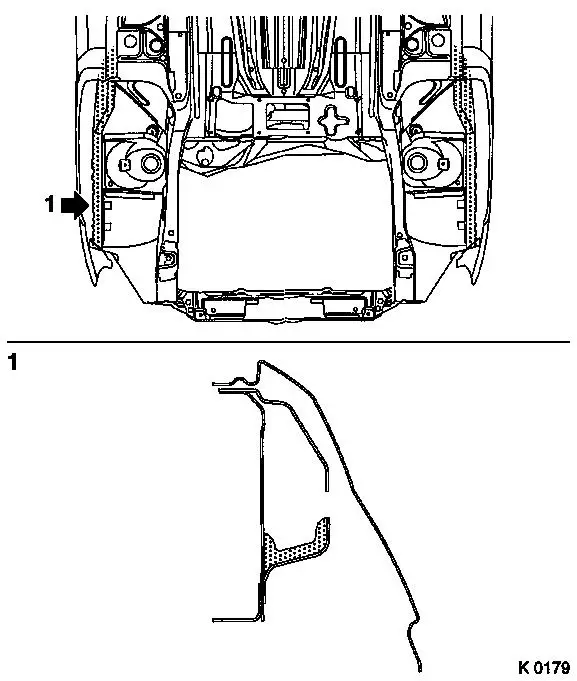

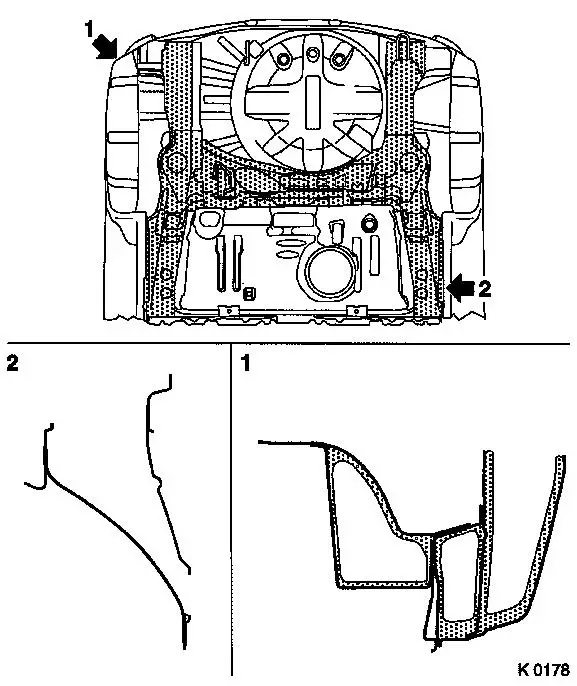

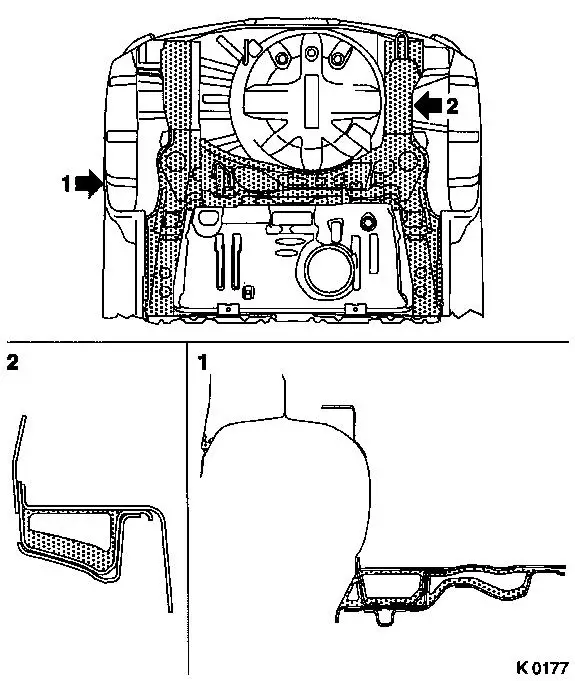

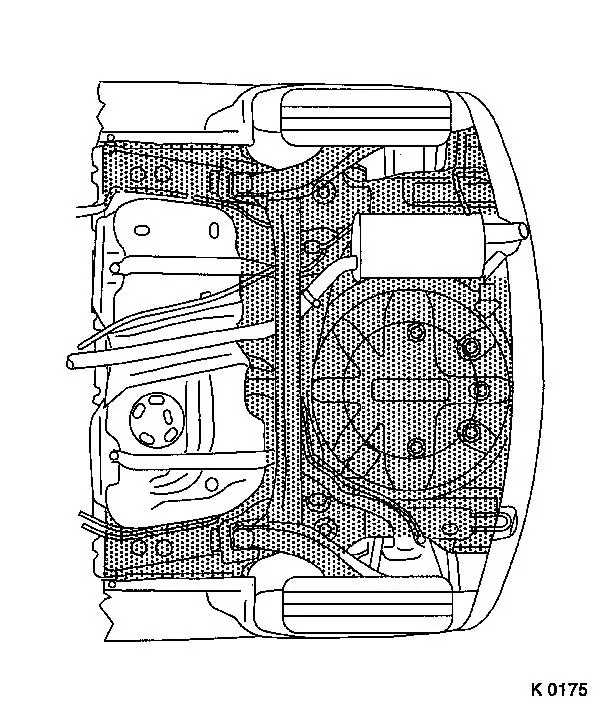

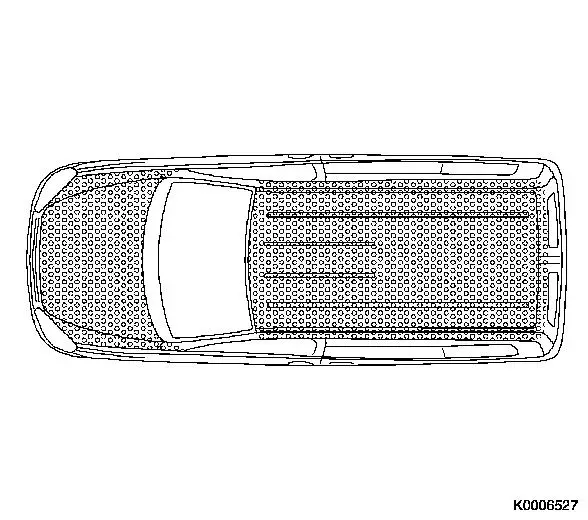

The interior of the body is painted manually. Plastic parts are provided with a special paint structure in separate processes prior to assembly. Cavity protection wax Model F 08, F 08 & W5L, F 68

Models F 08, F 08 & W5L, F 68, F 25, F 06

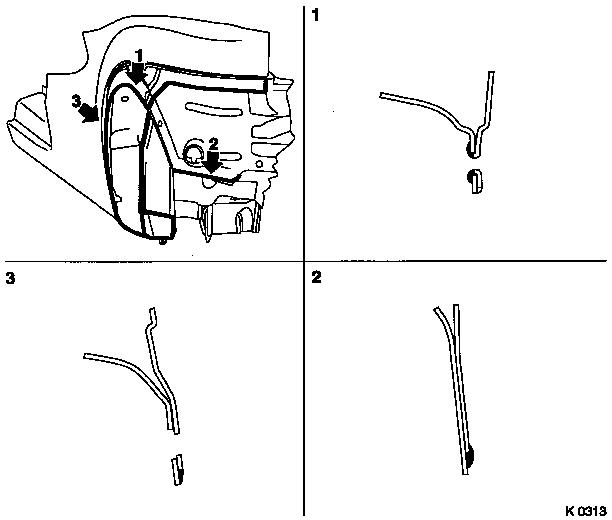

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

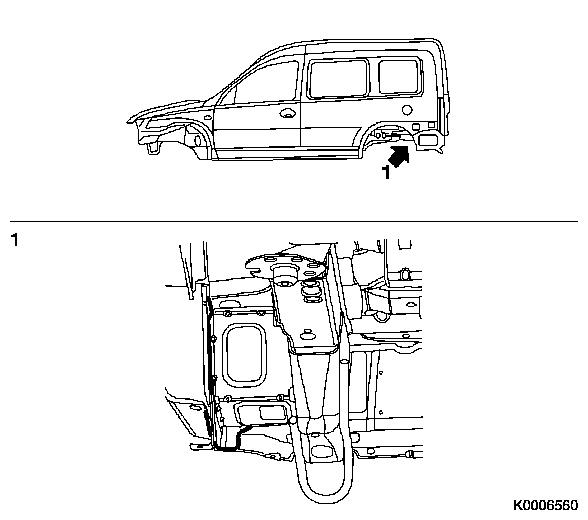

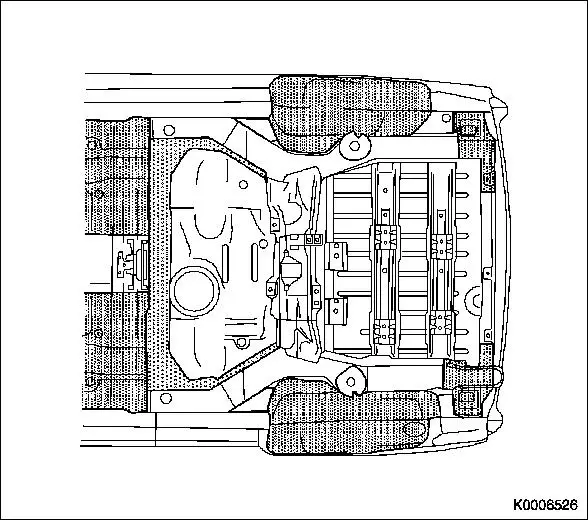

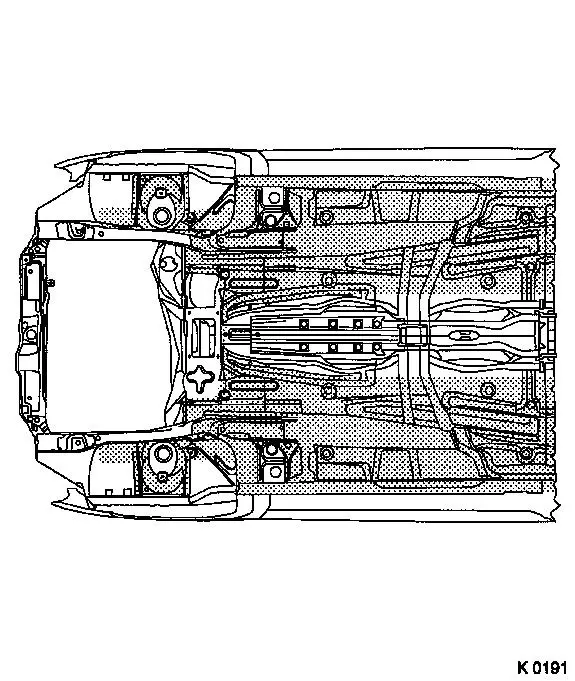

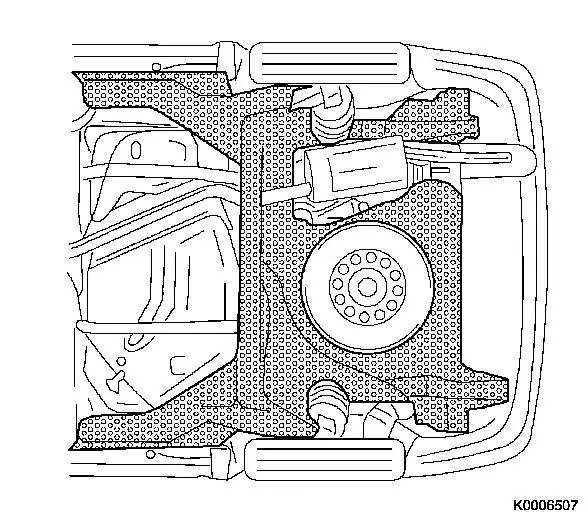

Underbody protection wax In the further production sequence, all vehicles are given an underbody protection wax to the vehicle underbody. The entire vehicle underbody and its body attaching parts are coated, such as, e.g.:

Catalytic converters and parts in the exhaust area are not coated. Advantages of underbody protection wax:

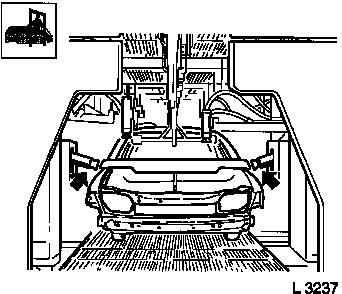

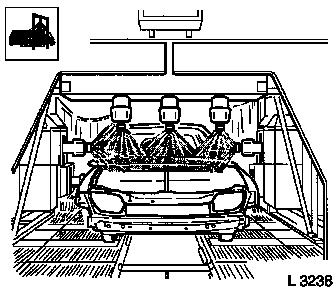

Underbody protection wax is applied in an automatic spraying operation. Models F 08, F 08 & W5L, F 68, F 25, F 06

Model F 08, F 08 & W5L, F 68

Models F 25, F 06

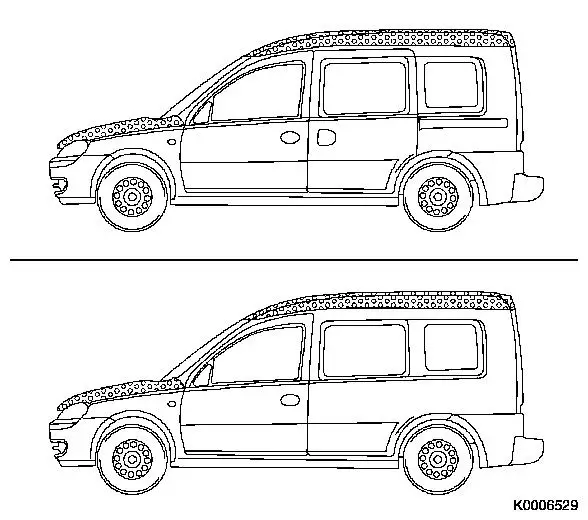

Bearing and Transit Protective Wax The final application of bearing and transit protective wax prevents corrosion damage caused by.

All vehicles are given bearing and transit protective wax in the following areas:

Particles which can damage the paint accumulate only on the surfaces accessible from above. Therefore, enclosed, vertical surfaces (front, side, rear) are not included in the wax coating. Model F 08, F 08 & W5L

Model F 68

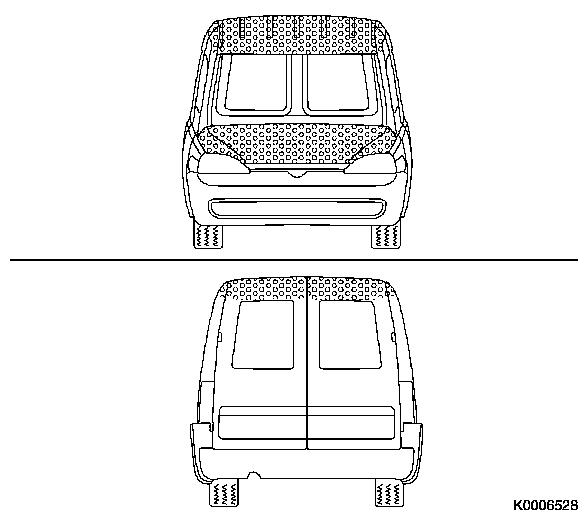

Models F 25, F 06

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||