|

Adjust timing (Y 17 DT, with air conditioning,

LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

Important: On vehicles from model

year 04 with ESP - the steering angle sensor loses its basic

adjustment each time the battery is disconnected. It must be

recalibrated.

|

| 2. |

Disconnect battery

|

| 3. |

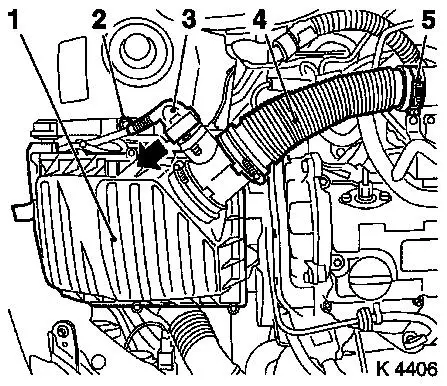

Remove air cleaner housing (1)

| • |

Disconnect wiring harness plug for hot film mass air flow meter

(3)

| – |

Release in direction of arrow

|

|

| • |

Remove air intake hose (4)

|

|

|

|

| 4. |

Detach front right wheel

|

| 6. |

Remove front right wheel

|

| 8. |

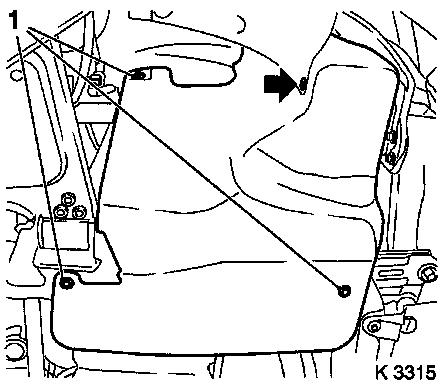

Detach ribbed V-belt cover

|

|

|

| 9. |

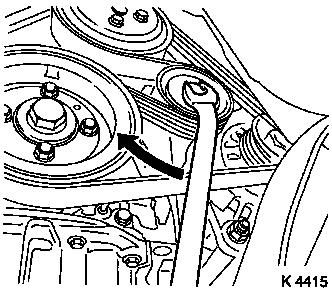

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

Note: Mark direction of

rotation

|

|

|

|

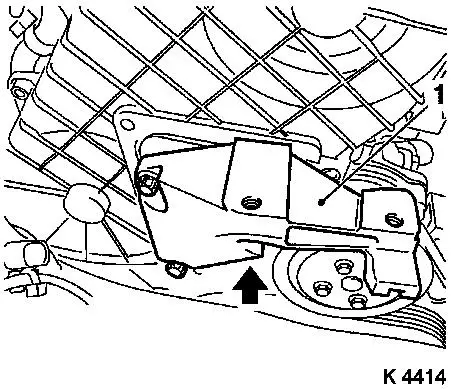

| 10. |

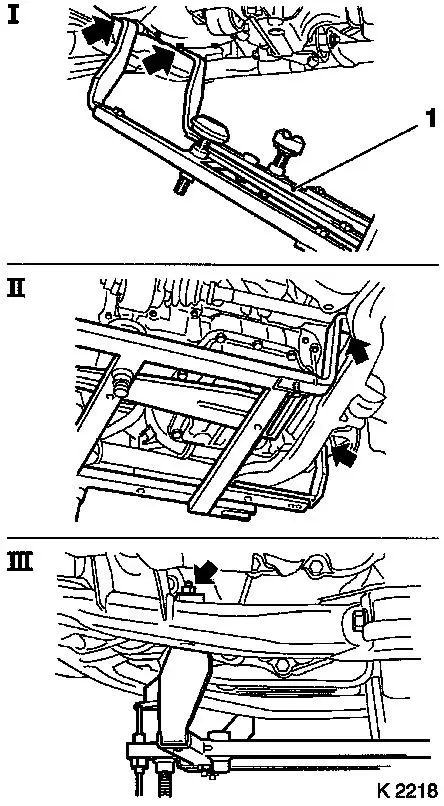

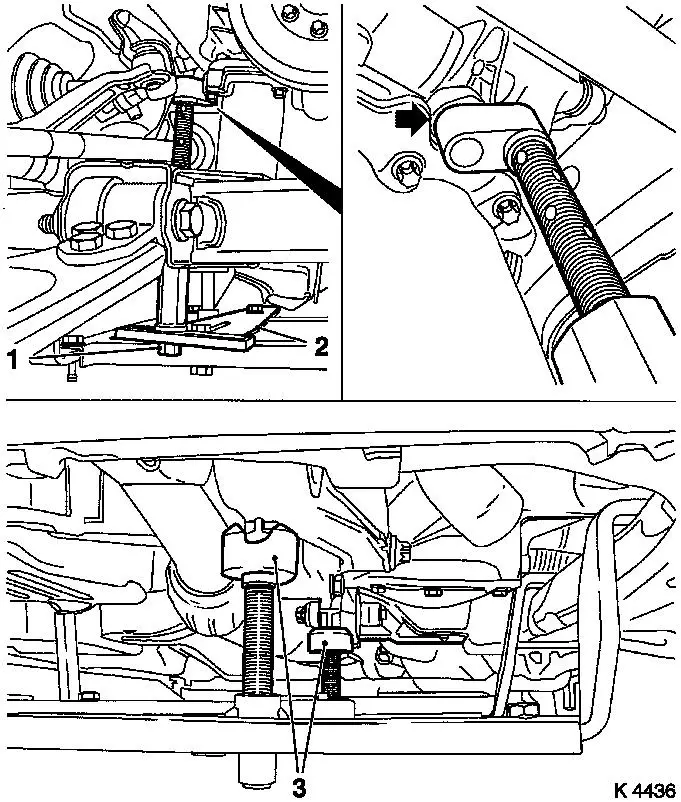

Attach KM-6169 (1)

| • |

Attach KM-6169 at left side of front

axle unit (arrows, fig.I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body (arrow, Fig. III)

|

|

|

|

| 11. |

Install support

| • |

An KM-6169

| – |

Adjust bracket (2) for support

|

|

|

| 12. |

Adjust supports

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at guide journals free of play

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

|

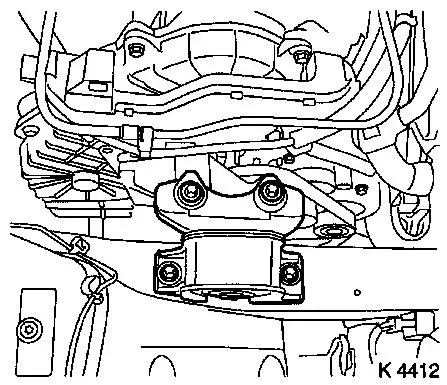

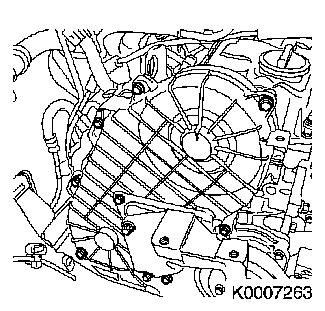

| 14. |

Remove right engine damping block

|

|

|

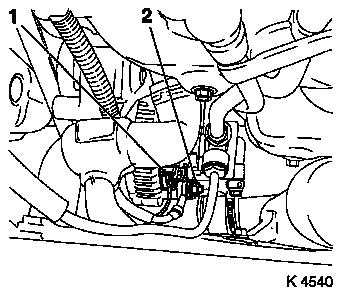

| 15. |

Detach alternator wiring harness

| • |

Disconnect wiring harness plug (1)

|

|

|

|

| 16. |

Remove wiring trough (1)

|

|

|

| 17. |

Detach right engine bracket (1)

|

|

|

| 18. |

Remove upper toothed belt cover

| • |

Remove 8 bolts

Note: Note dissimilar

bolt lengths

|

|

|

|

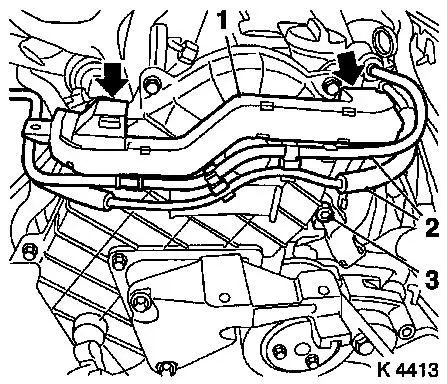

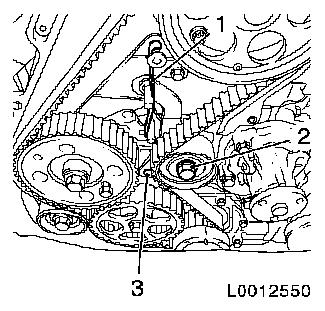

| 19. |

For toothed belt tension roller with leaf spring:

| • |

loosen toothed belt tensioner

| – |

Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

|

| – |

Remove tension spring (1)

|

|

|

|

|

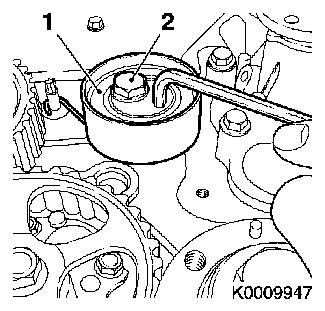

| 20. |

For toothed belt tension roller with spiral spring:

| • |

Loosen toothed belt tension roller (1)

| – |

Rotate toothed belt tension roller anticlockwise approx.

90°

|

|

|

|

|

| 21. |

Correct timings

Note: Twist camshaft

gear and injection pump gear such that TDC fixing bolts can be

screwed in.

|

| 22. |

Install toothed belt

| • |

Position toothed belt

Note: Toothed belt must

be taut from toothed belt drive gear via oil pump drive gear and

injection pump drive gear

|

| • |

For toothed belt tension roller with leaf spring:

|

| • |

Unscrew TDC-fixing bolt

|

| • |

Rotate crankshaft 60° against direction of engine

rotation

|

| • |

Tighten bolt of toothed belt tension roller

| – |

For toothed belt tension roller with spiral spring 49 Nm

|

| – |

For toothed belt tension roller with leaf spring 38.2 Nm

|

|

| • |

For toothed belt tension roller with leaf spring: unscrew bolt

(M10) from lower bore of toothed belt tensioner

|

|

| 23. |

Timing, Check

| • |

Turn crankshaft approx. 780° in direction of engine

rotation

| – |

At toothed belt drive gear bolt

|

|

| • |

Torsional vibration damper marking must be in line with pin on

oil pump cover

|

| • |

Install TDC-fixing bolt

Note: If the TDC fixing

bolts cannot be screwed in, basic adjustment must be repeated

|

| • |

Unscrew TDC-fixing bolts

|

|

| 24. |

Attach right engine bracket

| • |

Insert lower bolt

| – |

Into right engine bracket and right engine bracket adapter

|

|

| • |

Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

| • |

Tighten 3 bolts( 40 Nm )

|

|

| 25. |

Fasten upper part of toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

Note: Note dissimilar

bolt lengths

|

|

| 26. |

Install right engine damping block

| • |

To side member

| – |

Tighten bolts ( 40 Nm )

|

|

| • |

On engine bracket

| – |

Tighten bolts ( 60 Nm + 30° +

15° )

|

|

|

| 28. |

Attach alternator wiring harness

|

| 32. |

Install ribbed V-belt

Note: Pay attention to

running direction and installation position

| • |

Release ribbed V-belt tensioner

|

|

| 33. |

Attach ribbed V-belt cover

|

| 35. |

Install right front wheel

|

| 37. |

Fasten right front wheel

| • |

Tighten bolts ( 110 Nm )

|

|

| 38. |

Install air cleaner housing

| • |

Fasten air intake hose.

|

| • |

Connect wiring harness plug to hot film mass air flow meter

|

|

| 40. |

Calibrate steering angle sensor

| • |

Switch on ignition

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

|

|

| 41. |

Program volatile memories

|

|