|

Remove and install all pistons with con-rods (Z 14

XE, Z 16 YNG with air conditioning, RHD)

Warning: When using

vehicles running on natural gas, observe the particular procedures

and method of use, warning instructions and safety regulations.

Note: KM-6394 must be used as of model year 04 instead of

KM-6169-1 .

Note: The customer

should be informed of the choice between ECOService and

ECOService-Flex before the oil change.

Important: On vehicles as of

model year 04 with ESP - the steering angle sensor loses its basic

adjustment each time the battery is disconnected. It must be

recalibrated.

|

| 2. |

Disconnect battery

|

| 3. |

Drain coolant

| • |

Place collecting basin underneath.

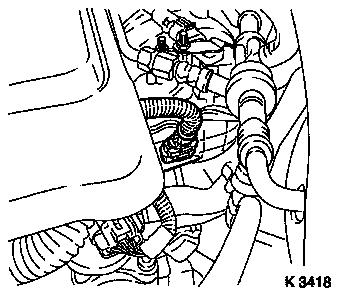

|

| • |

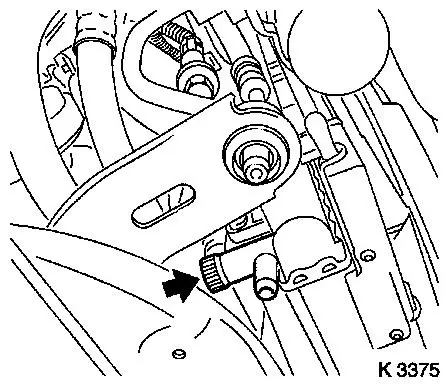

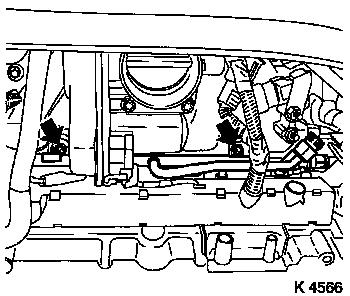

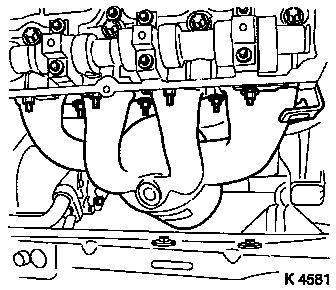

Open drain bolt (arrow)

|

|

|

|

| 4. |

Remove engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 5. |

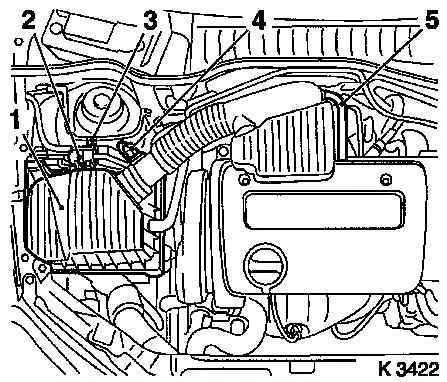

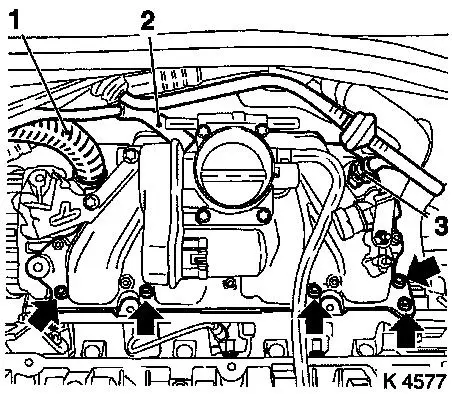

Remove air cleaner housing (1)

| • |

Disconnect wiring harness plug

| – |

Intake air temperature sensor (4), tank vent valve (2)

|

|

| • |

Remove air intake pipe

| – |

From throttle valve module

|

|

| • |

Detach engine vent hose (5)

|

|

|

|

| 6. |

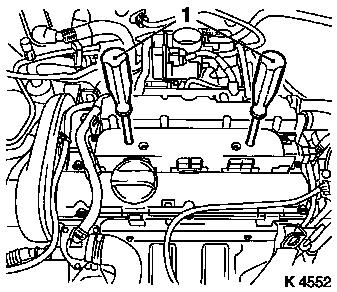

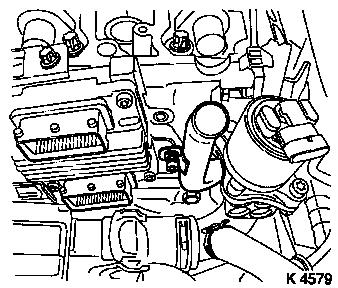

Remove ignition module

| • |

Disconnect wiring harness plug

|

Important: Do not tilt

|

| • |

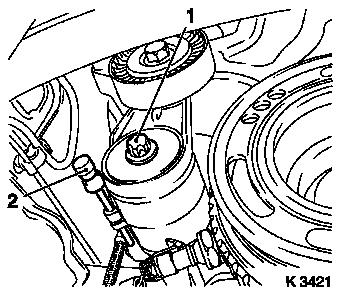

Extract using KM-6009 (1)

|

|

|

|

| 7. |

Remove preheater hoses for throttle body module

|

| 8. |

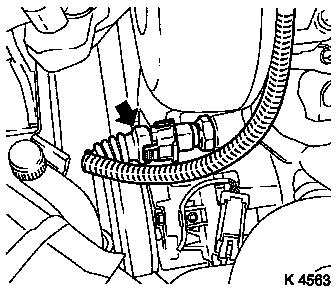

Remove coolant temperature sensor wiring harness plug

(arrow)

| • |

Release from rear of toothed belt cover

|

|

|

|

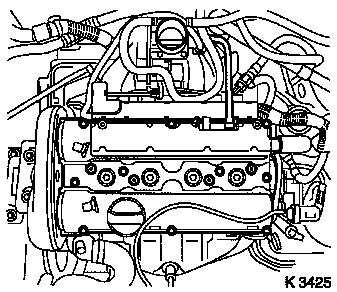

| 9. |

Remove cylinder head cover

| • |

Detach engine vent hose

|

| • |

Disconnect wiring harness plug for mixture regulating heated

oxygen sensor

|

|

|

|

| 10. |

Remove catalytic converter control oxygen sensor wiring harness

plug

| • |

Disconnect wiring harness plug

|

|

|

|

| 11. |

Loosen right front wheel.

|

| 13. |

Remove right front wheel.

|

| 15. |

Close coolant drain bolt

|

| 16. |

Drain engine oil

| • |

Place collecting basin underneath.

|

|

| 17. |

Remove ribbed V-belt cover

|

|

|

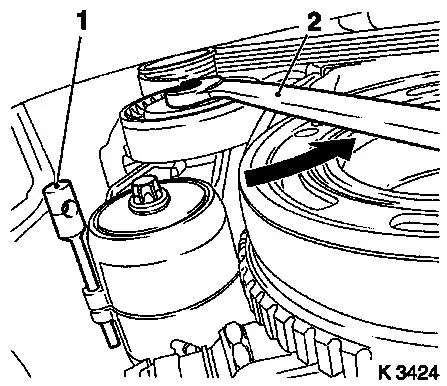

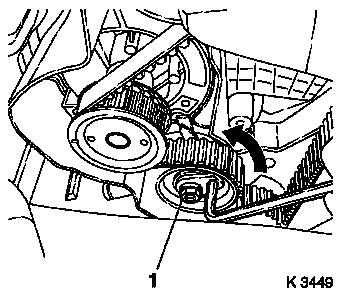

| 18. |

Remove ribbed V-belt

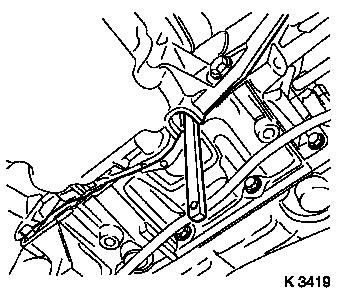

| • |

Tension ribbed V-belt tensioner in direction of arrow

| – |

Using KM-913-A (2) (SW 15)

|

|

| • |

Mark running direction.

|

|

|

|

| 19. |

Remove ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner.

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 20. |

Detach crankshaft ribbed V-belt pulley

| • |

Lever out front closure plug

|

|

|

|

| 21. |

Release lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 22. |

Install engine oil drain bolt

|

| 23. |

Loosen exhaust system

Important: When removing the

centre muffler, a catalytic converter, an exhaust manifold or an

exhaust manifold with catalytic converter, the exhaust system piece

remaining in the vehicle must be prevented from swinging

uncontrollably. The exhaust system piece with the flex pipe inside

can be secured for this purpose using suitable means, such as a

wire on the vehicle underbody. Bends in the flex pipe with an angle

as little as 5 – 10 degrees from the intended installation

position may result in damage with subsequent total failure of the

flex pipe.

|

| • |

Detach exhaust system

|

| • |

Detach front exhaust pipe

|

| • |

Suspend front exhaust pipe from left front axle body

|

|

| 24. |

Detach intake manifold support

|

|

|

| 25. |

Disconnect wiring harness plug for engine management

| • |

Crankshaft pulse generator, oil pressure switch

|

|

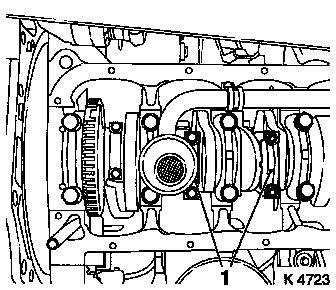

| 26. |

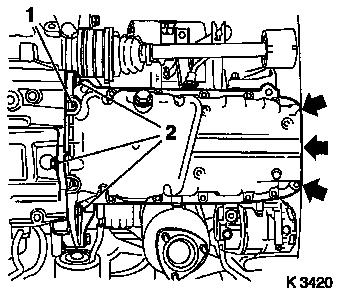

Remove oil pan

| • |

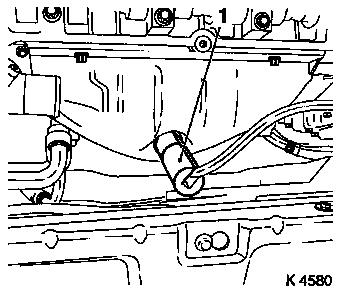

Lever out rear sealing plug (1)

|

| • |

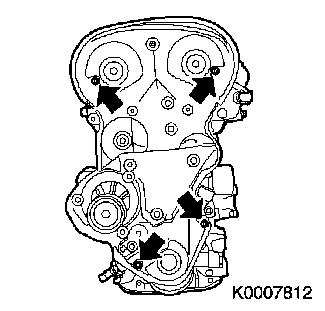

Oil pump

| – |

Remove 3 bolts (arrows)

|

|

|

|

|

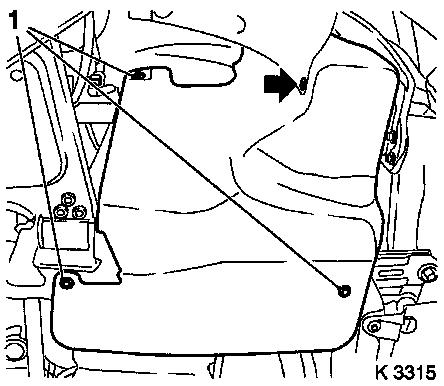

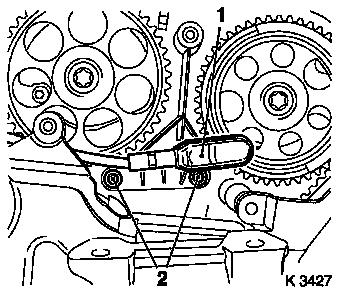

| 28. |

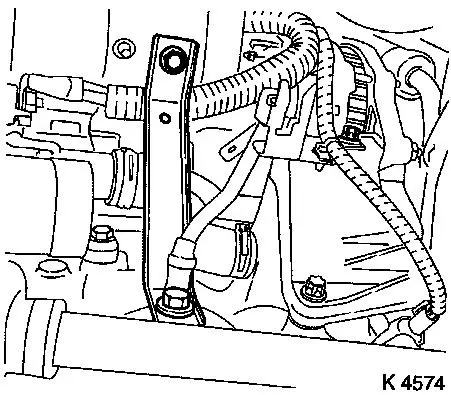

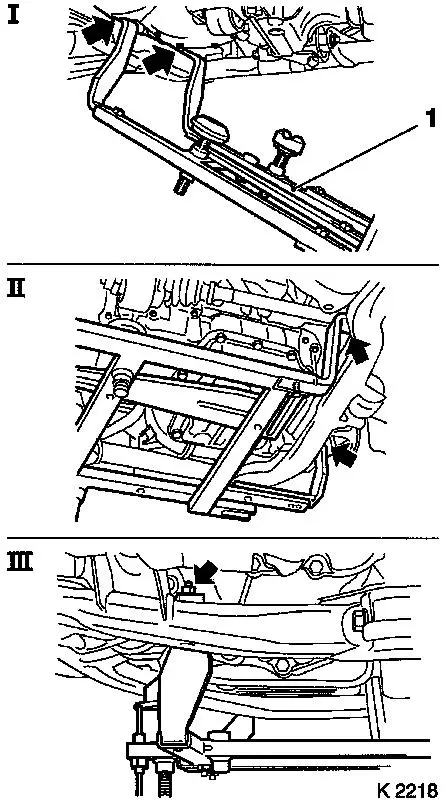

Attach KM-6169 (1)

| • |

Attach KM-6169 to left of front axle

body (arrows, illus. I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body (arrow, Illus. III).

|

|

|

|

| 29. |

Install support

| • |

An KM-6169

| – |

Adjust bracket (2) for support

|

|

|

| 30. |

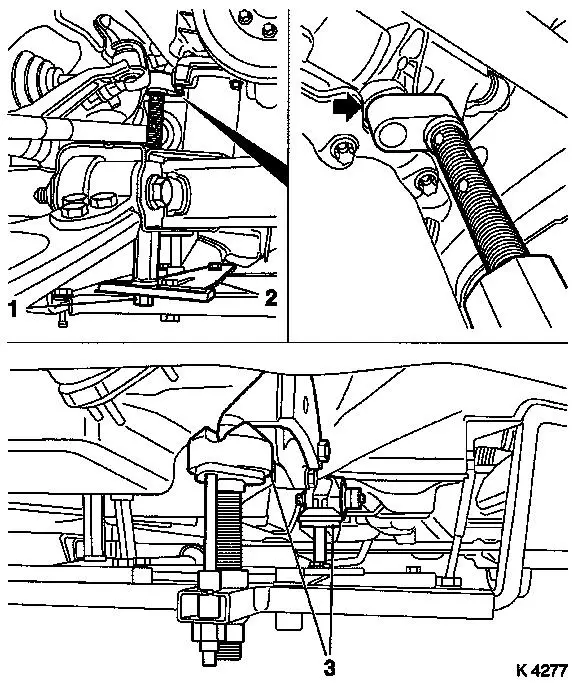

Adjust supports

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at the guide journals free of

play.

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

|

| 32. |

Remove right engine damping block

| • |

Loosen engine bracket adapter

|

| • |

Loosen engine damping block

|

|

| 33. |

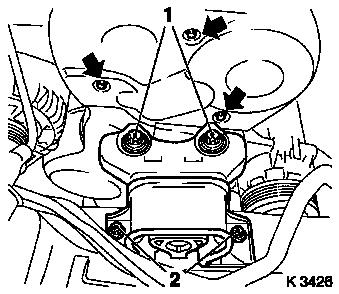

Remove upper part of toothed belt cover

| • |

Remove 3 bolts (arrows)

|

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 34. |

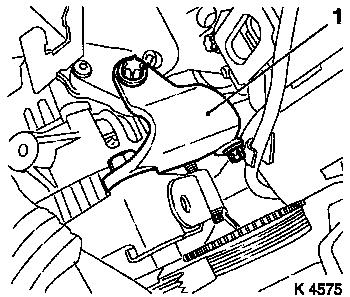

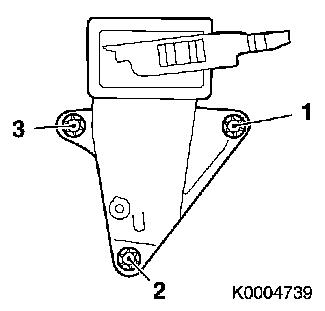

Remove camshaft sensor (1)

| • |

Disconnect wiring harness plug

|

|

|

|

| 35. |

Remove lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

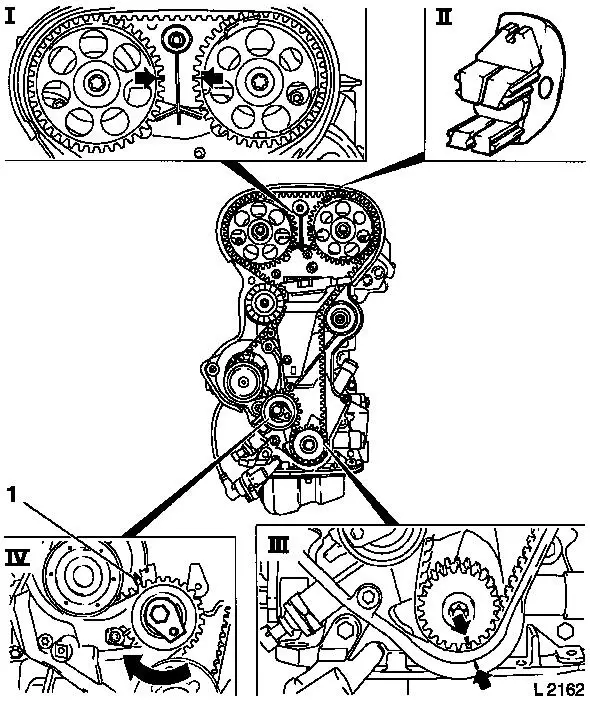

| 36. |

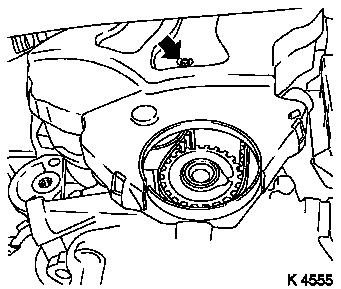

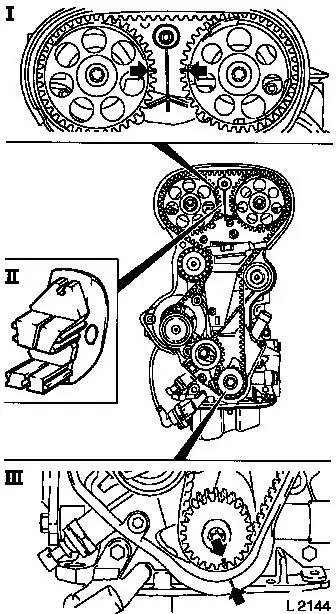

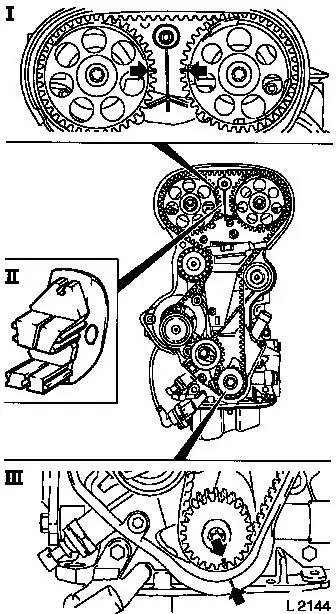

Set 1st cylinder to TDC of combustion stroke

| • |

Install crankshaft V-belt pulley bolt

|

| • |

Set crankshaft to mark.

| – |

Turn crankshaft evenly

Note: Marks on drive

gear toothed belt and rear toothed belt cover must align (III).

|

|

| • |

Fix camshaft sprockets in position.

Note: Marks must be

opposite one another and aligned with the top edge of the cylinder

head (I)

|

|

| 37. |

Remove toothed belt

| • |

Release toothed belt tension roller (IV)

Note: Mark running

direction.

| – |

Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

just before left stop.

|

|

|

|

|

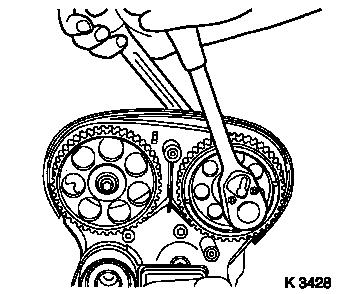

| 38. |

Remove camshaft sprockets

| • |

Remove 2 bolts

| – |

Counterhold camshafts at hexagonal section

|

|

|

|

|

| 39. |

Remove intake side toothed belt guide roller

|

| 40. |

Remove exhaust side toothed belt guide roller

|

| 41. |

Remove right engine bracket (3)

|

| 42. |

Remove toothed belt tension roller

|

|

|

| 43. |

Remove toothed belt drive pulley

| • |

Unscrew crankshaft ribbed V-belt pulley bolt

|

| • |

Remove toothed belt drive pulley

|

|

| 44. |

Remove rear of toothed belt cover

| • |

Remove 4 bolts (arrows)

|

|

|

|

| 45. |

Remove alternator shackle (1)

| • |

Swing alternator backwards.

|

|

|

|

| 46. |

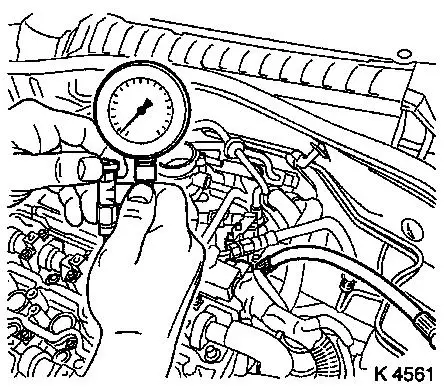

Reduce fuel pressure

Important: Observe safety

measures and national legislation.

|

| • |

With KM-J-34730-91

|

| • |

Unscrew test connection protective cap

|

|

|

|

| 47. |

Remove fuel line

| • |

From fuel distributor pipe

|

|

| 48. |

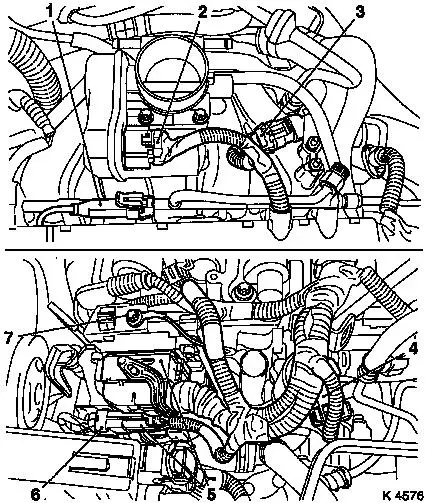

Remove wiring harness for engine management

| • |

Disconnect wiring harness plug

| – |

Throttle body module (2), knock sensor (1), intake pipe

pressure sensor (3), exhaust recirculation valve (4), engine

control unit (5), combination plug (6)

|

|

| • |

Remove ground cable (7)

|

|

|

|

| 49. |

Remove fuel distributor pipe

| • |

Remove 2 bolts (arrows)

|

| • |

Remove wiring harness for engine management together with

injectors

|

|

|

|

| 50. |

Remove intake manifold

| • |

Remove brake servo vacuum line (3)

|

| • |

Unclip wiring harness (1)

|

| • |

Remove tank vent valve line (2)

|

| • |

Remove 5 bolts (arrows)

|

|

|

|

| 51. |

Remove upper radiator hose

|

| 53. |

Remove engine vent flange

| • |

From engine control unit bracket

|

|

|

|

| 54. |

Remove heated oxygen sensor for mixture regulation

|

|

|

| 55. |

Remove exhaust manifold heat shield

|

| 56. |

Remove exhaust manifold

|

|

|

| 57. |

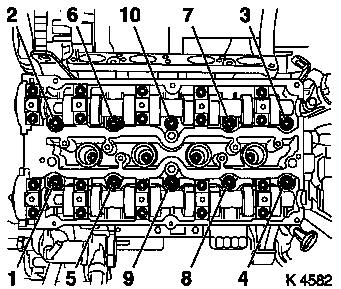

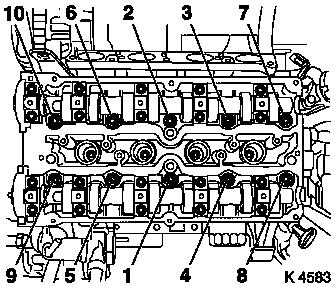

Remove cylinder head bolts

| • |

Remove 10 bolts

Note: Undo bolts in

order shown.

|

|

|

|

| 58. |

Remove cylinder head

Note: 2nd mechanic

required.

Important: Place cylinder head on

wooden blocks.

|

| • |

Remove cylinder head gasket

|

|

| 60. |

Remove con-rod bearing cap

Note: Observe cylinder

order.

| • |

Mark con-rods with con-rod bearing caps

|

Important: The mating surfaces of

the cod-rods and con-rod bearing caps form an individual fit and

must not be damaged or interchanged. Do not lay on mating

surfaces.

|

| • |

Push piston with con-rod upwards

|

|

|

|

| 65. |

Remove con-rod bearing cap

Note: Observe cylinder

order.

| • |

Mark con-rods with con-rod bearing caps

|

Important: The mating surfaces of

the cod-rods and con-rod bearing caps form an individual fit and

must not be damaged or interchanged. Do not lay on mating

surfaces.

|

| • |

Push piston with con-rod upwards

|

|

| 68. |

Remove con-rod bearing shells

| • |

Mark con-rod bearing shells

Note: Observe

order.

|

|

| 70. |

Insert con-rod bearing shells

| • |

In con-rod, con-rod bearing cap

|

|

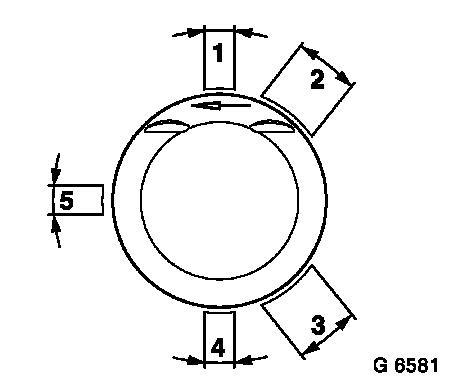

| 71. |

Adjust piston ring gaps

| • |

Turn piston rings

| – |

Upper rings in position (1)

|

| – |

Middle rings in position (4)

|

|

| • |

Turn oil scraper ring

| – |

Intermediate ring in position (5)

|

| – |

Steel band rings in position (2) or (3)

|

|

|

|

|

| 72. |

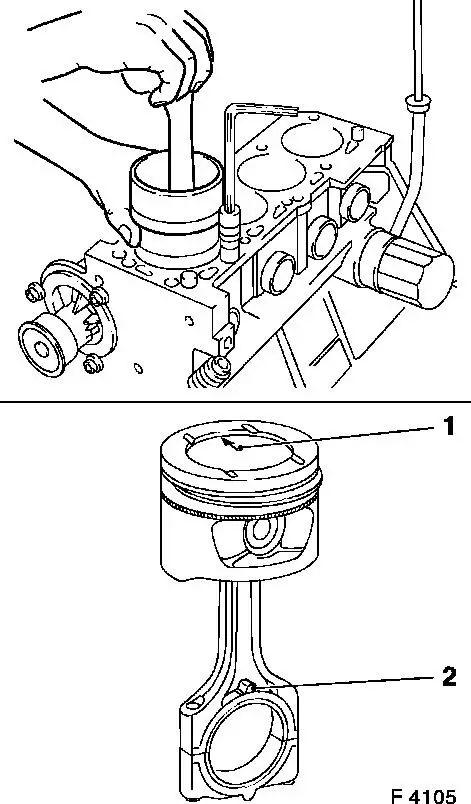

Install piston

| • |

Coat piston and cylinder bores with engine oil

|

Important: Arrow (1) on bottom of

piston points to engine timing side. Bead (2) on con-rod should

face transmission side

|

| • |

Compress piston rings with piston ring tensioner

|

|

|

|

| 74. |

Attach con-rod bearing cap

| • |

Coat con-rod journal with engine oil

|

Important: Bead on con-rod

bearing cap should face transmission side

|

| • |

Tighten bolts ( 25 Nm + 30°

)

|

|

| 75. |

Turn crankshaft

| • |

In direction of engine rotation by 180°

|

|

| 77. |

Install piston

| • |

Coat piston and cylinder bores with engine oil

|

Important: Arrow on bottom of

piston points to engine timing side. Bead on con-rod should face

transmission side

|

| • |

Compress piston rings with piston ring tensioner

|

|

| 79. |

Attach con-rod bearing cap

| • |

Coat con-rod journal with engine oil

|

Important: Bead on con-rod

bearing cap should face transmission side

|

| • |

Tighten bolts ( 25 Nm + 30°

)

|

|

| 81. |

Clean sealing surfaces

| • |

Cylinder block, crankshaft bearing bridge, oil pan, cylinder

head, timing case, exhaust manifold, oil filter housing, thermostat

housing, cylinder head cover

|

|

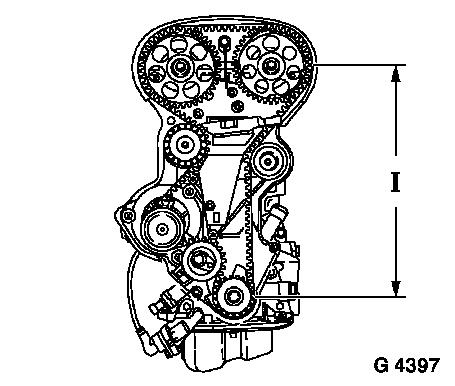

| 82. |

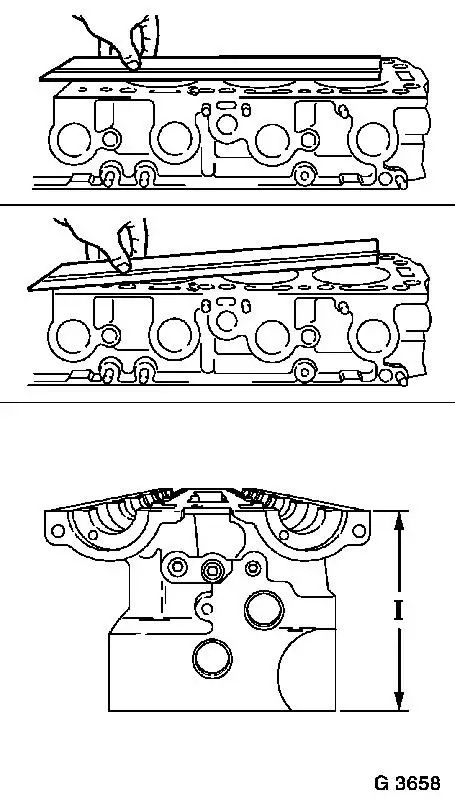

Check for plane surface

| • |

Cylinder head, cylinder block

|

| • |

With straightedge, feeler gauge

|

| • |

Measure cylinder head height

| – |

Sealing surface to sealing surface 134.90 - 135.10 mm (I)

|

|

|

|

|

| 83. |

Inspect components

| • |

Cylinder block, cylinder head, exhaust manifold, intake

manifold, cylinder head cover

|

|

| 84. |

Replace cylinder head gasket

| • |

Attach cylinder head gasket

Note: OBEN/TOP mark

must face upwards.

|

|

| 85. |

Attach cylinder head

Note: Second person

required

|

| 86. |

Fasten cylinder head

| • |

Replace cylinder head bolts

| – |

Screw in bolts by several threads

|

|

| • |

Tighten cylinder head bolts ( 25 Nm +

90°+ 90°+ 90° + 45° )

Note: Note tightening

sequence.

|

|

|

|

| 87. |

Attach exhaust manifold

|

| 88. |

Attach exhaust manifold heat shield

|

| 89. |

Install oxygen sensor, mixture regulation, heated

| • |

Apply special grease (black) to thread

|

| • |

using KM-6179 ( 30 Nm )

|

|

| 90. |

Install engine vent flange

|

| 92. |

Install intake manifold

|

| 93. |

Install fuel distributor pipe

|

| 94. |

Attach wiring harness for engine management

| • |

Clip in cable tie

| – |

With oil pressure switch and crankshaft sensor

|

|

|

| 95. |

Install upper radiator hose

|

| 96. |

Attach fuel line

| • |

Tighten union nut ( 15 Nm )

|

|

| 97. |

Install alternator shackle

|

| 98. |

Install rear toothed belt cover

|

| 99. |

Install toothed belt drive gear

| • |

Install crankshaft V-belt pulley bolt

|

|

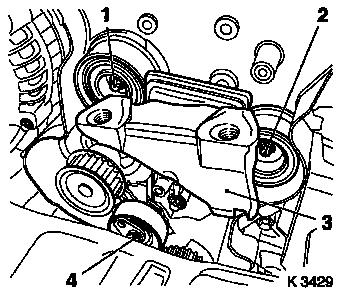

| 100. |

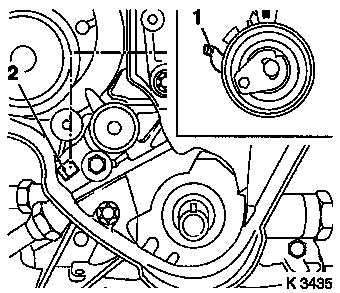

Install toothed belt tension roller

Important: Detent lever (1) of

toothed belt tension roller must engage in guide web (2) of oil

pump.

|

| • |

Bolt in bolt

Note: Adjust toothed

belt tension before tightening bolt.

|

|

|

|

| 101. |

Install right engine bracket

| • |

Insert bolts with locking compound (red)

|

| • |

Tighten bolts ( 65 Nm + 45° -

60° )

Note: The rotating

angle to be applied must be set by eye.

|

| • |

Note tightening sequence (1 - 3).

|

|

|

|

| 102. |

Install intake side toothed belt guide roller

Important: The toothed belt guide

roller with the greater diameter is installed at the intake

side.

|

| • |

Tighten bolt 25 Nm

|

|

| 103. |

Install exhaust side toothed belt guide roller

|

| 104. |

Install camshaft sprockets

Note: Attach camshaft

sprocket with cylinder recognition to exhaust camshaft.

|

| 105. |

Fasten camshaft sprockets

Note: Second person

required

| • |

Tighten bolts ( 50 Nm + 60° +

15° )

| – |

Counterhold camshafts at hexagonal section

|

|

|

| 106. |

Fix camshaft sprockets in position.

Note: Marks must be

opposite one another and aligned with the top edge of the cylinder

head (I)

| • |

Use KM-852 (II)

| – |

Turn the camshafts at hexagonal section

|

|

|

| 107. |

Lock crankshaft

| • |

Set crankshaft to mark.

| – |

Turn crankshaft evenly

Note: Marks on drive

gear toothed belt and rear toothed belt cover must align (III).

|

|

|

|

|

| 108. |

Install toothed belt

Note: Pay attention to

direction of travel and timing marks.

| • |

Position toothed belt

Note: Tensioned side

must be taut (I).

|

|

|

|

| 109. |

Tension toothed belt

| • |

Tension toothed belt tension roller

| – |

Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

|

|

| • |

Fasten toothed belt tension roller bolt (1)

|

|

|

|

| 111. |

Timing, Check

| • |

Turn crankshaft (720°)

| – |

At crankshaft ribbed V-belt pulley bolt

Note: In direction of

engine rotation.

|

|

| • |

Set crankshaft to mark.

Note: Marks on drive

gear toothed belt and rear toothed belt cover must align (III).

|

| • |

Use KM-852 (II)

Note: Marks must be

opposite one another and aligned with the top edge of the cylinder

head (I)

|

|

|

|

| 113. |

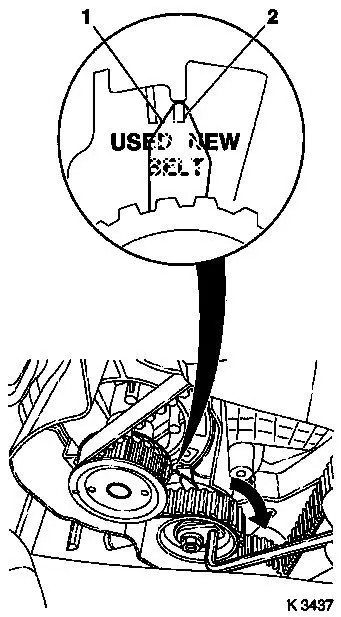

Adjust toothed belt tension

| • |

Release toothed belt tension roller

|

| • |

Turn adjustment eccentric in the direction of the arrow

(clockwise) until pointer (1) is aligned with the notch mark at the

toothed belt tension roller (2).

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW

|

|

| • |

Tighten toothed belt tension roller bolt 20 Nm

|

|

| 114. |

Check toothed belt tension

| • |

Turn crankshaft (720°)

Note: Pointers on the

toothed belt tension roller and notch mark must align.

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW

|

|

|

|

|

| 116. |

Attach camshaft sensor

| • |

Insert bolts with locking compound (red)

|

|

| 117. |

Install lower part of toothed belt cover

| • |

Clip to rear toothed belt cover

|

|

| 118. |

Install upper part of toothed belt cover

| • |

Clip to rear toothed belt cover

|

|

| 119. |

Connect wiring harness plug from camshaft sensor

| • |

Connect wiring harness plug from camshaft sensor.

|

|

| 120. |

Install right engine damping block

| • |

Fasten engine bracket adapter

| – |

Tighten bolts ( 60 Nm + 30° -

45° )

|

|

| • |

Fasten engine damping block

|

|

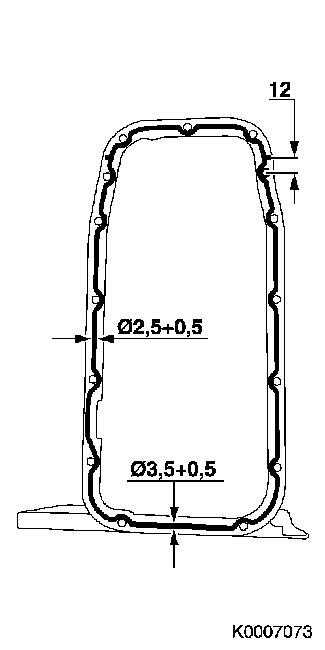

| 126. |

Install oil pan

Important: Complete installation

work within 10 minutes

|

| • |

Screw in bolts

|

| • |

Insert rear closure plug

|

|

|

|

| 127. |

Attach intake manifold support

|

| 128. |

Attach exhaust system

| • |

Attach oxygen sensor (catalytic converter control) cable to

intake manifold support and fold upwards

|

|

| 129. |

Install ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner.

|

|

| 130. |

Attach crankshaft ribbed V-belt pulley

| • |

Tighten bolt 95 Nm + 30° +

15°

|

| • |

Insert front sealing plug

|

|

| 131. |

Install ribbed V-belt

Note: Note running

direction and installation position

| • |

Release ribbed V-belt tensioner

|

|

| 132. |

Install ribbed V-belt cover

|

| 134. |

Mount right front wheel.

|

| 136. |

Fasten right front wheel.

|

| 137. |

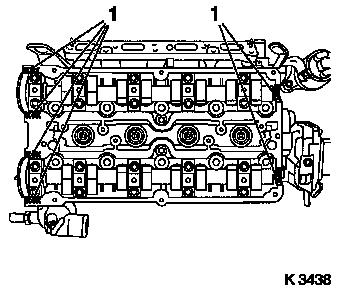

Install cylinder head cover

Important: Complete installation

work within 10 minutes

|

| • |

Tighten bolts 8 Nm

|

| • |

Attach engine vent hose

|

| • |

Connect cable harness plug of oxygen sensor, mixture

regulation, heated

|

|

|

|

| 138. |

Install catalytic converter control oxygen sensor wiring

harness plug

| • |

Connect wiring harness plug.

|

|

| 139. |

Install preheater hoses for throttle body module

| • |

Connect wiring harness plug for coolant temperature sensor

|

|

| 140. |

Attach brake servo vacuum line

|

| 141. |

Install ignition module

| • |

Connect wiring harness plug.

|

|

| 142. |

Install air cleaner housing

| • |

Install air intake hose.

|

| • |

Attach engine vent hose

|

| • |

Install air intake pipe

|

| • |

Clip in tank vent valve

|

| • |

Connect wiring harness plug.

|

|

| 143. |

Install engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 145. |

Calibrate steering angle sensor

| • |

Switch on ignition

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

|

|

| 146. |

Pour in engine oil and coolant

| • |

Note prescribed quantities of engine oil and coolant

|

| • |

Start engine and allow to run until oil pressure telltale

extinguishes.

|

| • |

Check engine oil level, if necessary correct.

Note: Top up and bleed

cooling system – see operation "Cooling System, Top Up and

Bleed".

|

|

| 147. |

Reset service interval using TECH 2

Note: If the customer

chooses ECOService, connect TECH 2 and reprogram the engine control

unit. Reset the service interval using TECH 2 - see operation

"Engine oil change".

|

| 148. |

Fill out the service sticker

Note: Fill out the

service sticker - see operation "Flexible maintenance

intervals"

|

| 149. |

Program volatile memories

|

|