Field Remedy: 2313

| Subject: |

Engine compartment electronics module -

Water ingress |

| Models: |

Engines: |

Option: |

| Corsa-D 2008... |

All |

|

| Complaint: |

Bad or no engine running / MIL-Lamp on /

Several electrical malfunctions / Discharged battery. |

| Cause: |

Water ingress in engine compartment

electronics module. |

| Production: |

Modified parts have been introduced in

production as of VIN W0L0SDL0886089257 (plant Eisenach), VIN

W0L0SDL0884266553 (plant Zaragoza). |

Remedy:

In case of customer complaint the electric connectors in the engine

compartment electronics module have to be checked for corrosion and

if necessary restored. Additional sealing operations have to be

carried out as well.

Working procedure:

1. Open bonnet.

2. Disconnect battery.

3. Detach cover engine compartment electronics module.

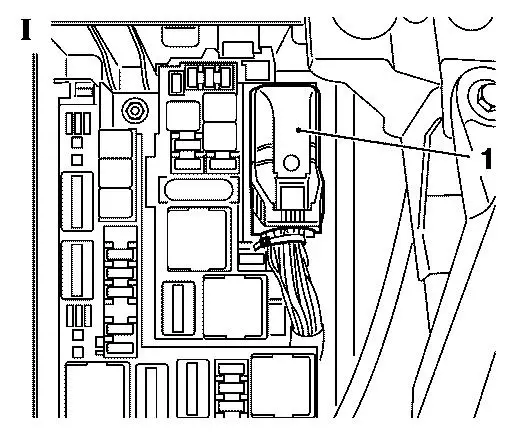

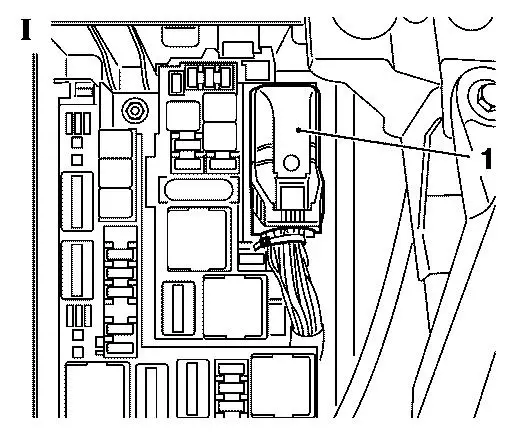

4. Disconnect connector (1) and pull it off upwards (picture I).

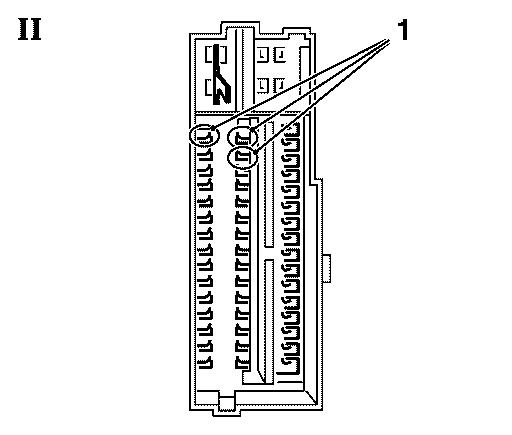

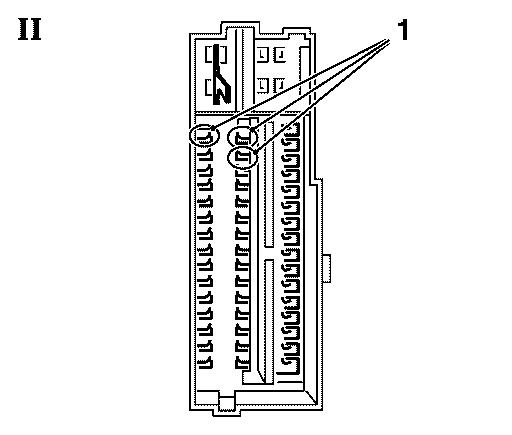

5. Check connector pins for corrosion (picture II)

- If connector pins and crimps show indication of corrosion, they

have to be removed from the connector terminal, cleaned and

again applied into the connector. Removing and installing of the

connector pins is mentioned below beginning with step 7.

- If contact areas of the connector pins are already damaged by

corrosion they have to be replaced. The working procedure is

mentioned below beginning with step 6.

Note:

Maximum 6 connector pins are allowed to be replaced. If more

than 6 connector pins are damaged the front and the rear body

wiring harness have to be replaced.

Note:

Connector pin number 16, 33 and 34 (1) belong to the

Airbag-System. If one of these connector pins shows corrosion

the front and the rear body wiring harness have to be replaced

as well.

Note:

If the front and the rear body wiring harness have to replaced,

the accordant wiring harness code has to be observed.

Identification of wiring harness can be carried out by a label

on the wiring harness behind the left service lid in the luggage

compartment or by means of Tech 2 in the Body-Control-Module.

6. Remove wind protection panel

- see working procedure "Replace wind protection panelling",

group "A", Service-Instruction Corsa-D.

(Document number 01501230)

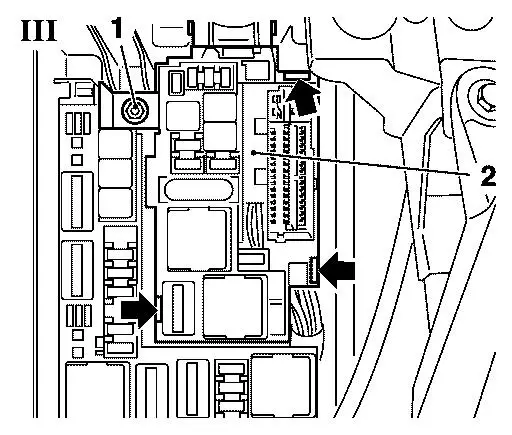

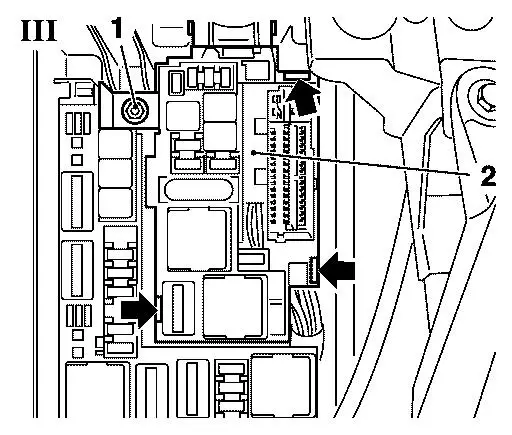

7. Remove connector inset from engine compartment electronics

module (picture III)

- Unscrew 1x nut (1)

- Unlock 3x latch (arrows) with screwdriver

- Detach connector inset (2) upwards and slew it clockwise

to the side.

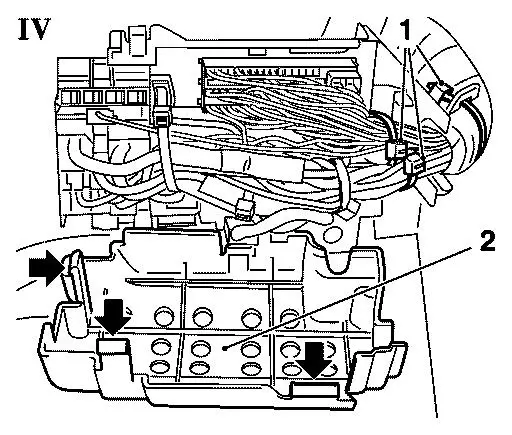

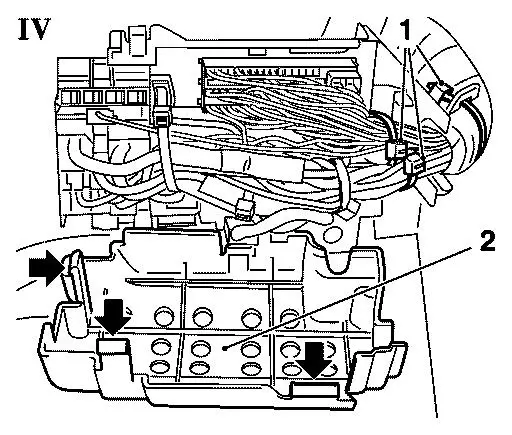

8. Open connector inset (picture IV)

- Unlock cover (2) on the bottom of connector inset 3x (arrows)

and detach

- Remove 3x cable strap (1).

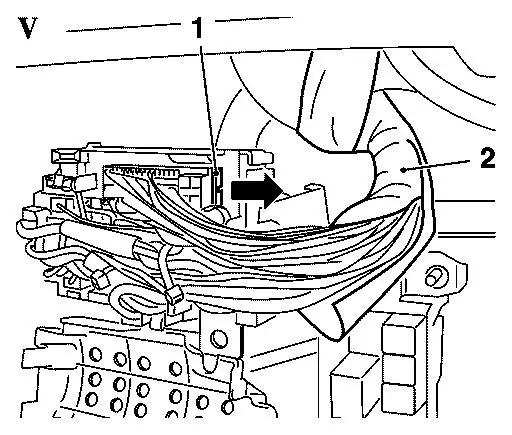

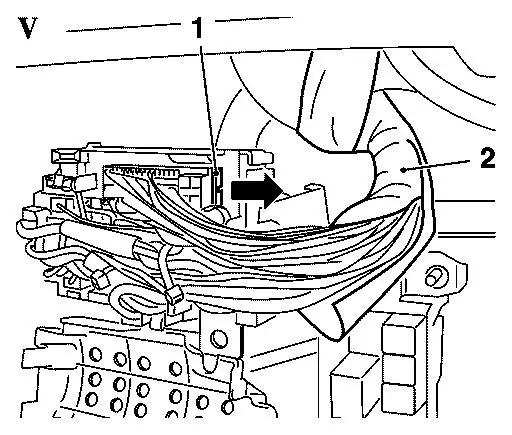

9. Unlock locking comb connector locking (picture V)

- Pull locking comb (1) with screwdriver into direction of the

arrow

- Split wiring harness isolation (2) about 10 cm and cut it off.

10. Eject damaged connector pin with special tool MKM-923-1 from

connector.

11. Cut ejected cable direct behind connector pin and bare wire

about 3 mm.

Note:

If corrosion has advanced up to the copper cable cut accordingly

longer.

12. Bare repair cable about 3 mm.

13. Shorten shrinkable tubing to a length of about 30 mm.

14. Connect repair cable and ejected cable with connecting sleeve

Note:

Push up shrinkable tubing before.

15. Push shrinkable tubing over connecting point and it heat up

with a hot air blower until hotmelt adhesive escapes even.

Note:

Avoid damages to the other cables by heat.

16. Plug connector pin into connector in its original position.

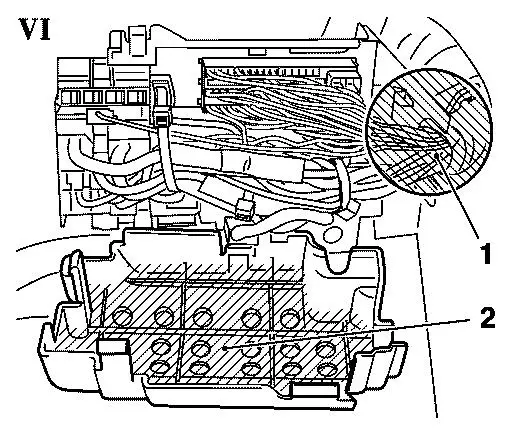

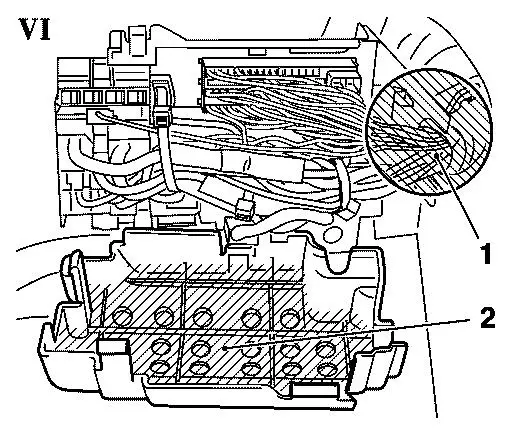

Note:

Step 10. till 16. have to be carried out for all damaged connector

pins maximum 6 pieces). Attend for offset of the several

connecting points. Connecting points have to be located only in

the hatched area (2, picture VI). In area (1) no connecting points

are allowed to be located.

Note:

The valid instructions for the repair of wiring harnesses

have to be observed, quod vide "Safety regulations of electrics/

electronics", group "N", Service-Instruction Corsa-D

(Document number 00026357).

17. Insert locking comb connector pins and lock it.

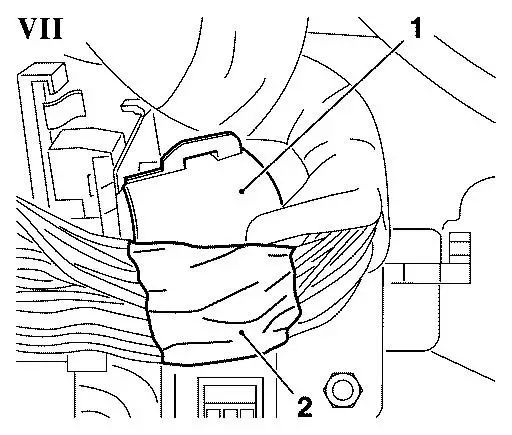

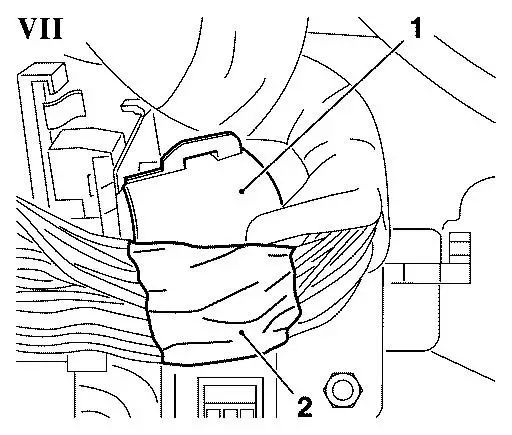

18. Seal wiring harness (picture VII)

- Take off the half amount of the seal plasticine (2) from the

repair kit and knead it between the cables in the area of the

wiring harness stabiliser (1).

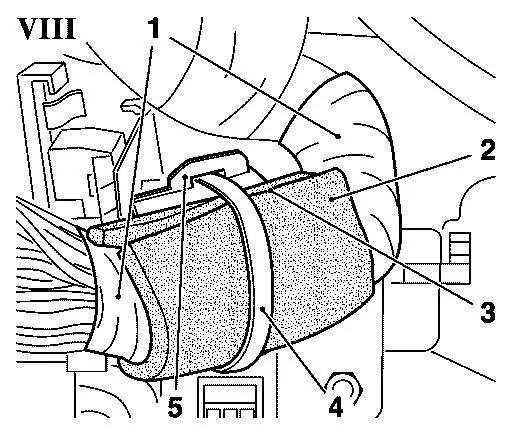

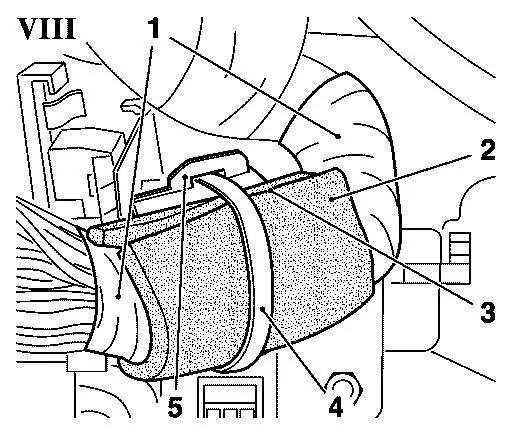

19. Isolate wiring harness (picture VIII)

- Laminate bared area of wiring harness with insulation tape (1)

completely

Note:

To ensure a better distribution of seal plasticine inside

attract insulation tape solid.

Note:

Use PVC-Tape, no textile tape.

- Affix self-adhesive sponge rubber mat (2) as shown onto wiring

harness

Note:

Beginnings (3) have to show upwards.

- Insert caple strap (4) into wiring harness stabiliser (5) and

tighten.

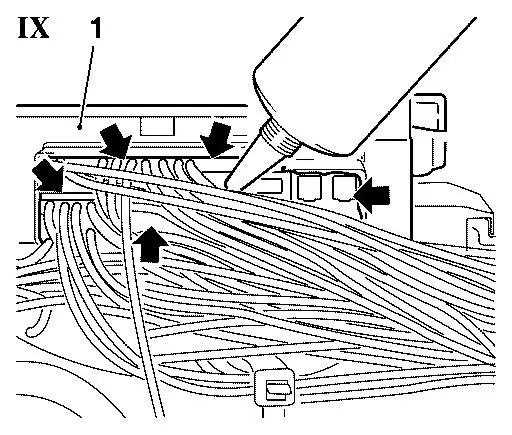

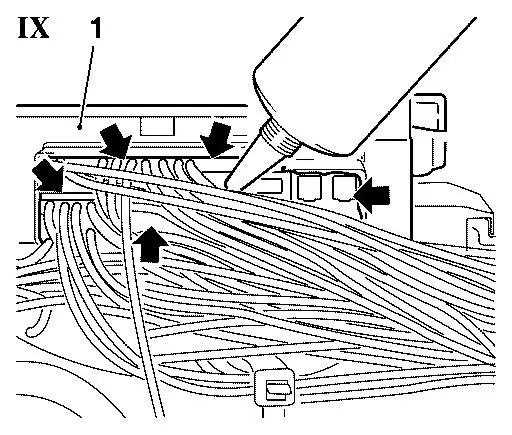

20. Seal underside of plug connection front body wiring harness

with special grease

- Fill all cells of plug connection (1, picture IX) front body

wiring harness from the underside completely with special grease

(P/N 09163339 - arrows).

21. Close connector inset

- Attach 2x cable strap and tighten

- Close cover until latches clip in.

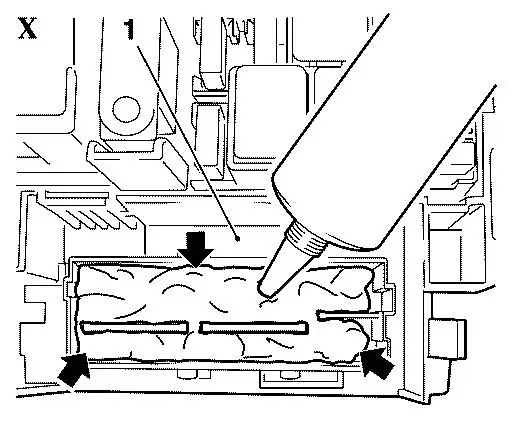

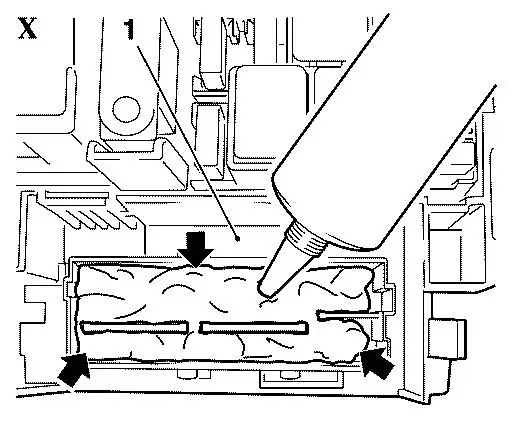

22. Seal upper side of plug connection front body wiring harness

with special grease

- Fill cell on upper side of plug connection (1, picture X) with

special grease (P/N 09163339 - arrows) until all connector pins

are covered completely.

Note:

During working with special grease, take care that no other areas

get in contact with the special grease as the sealing compound

will not adhere on areas already coated.

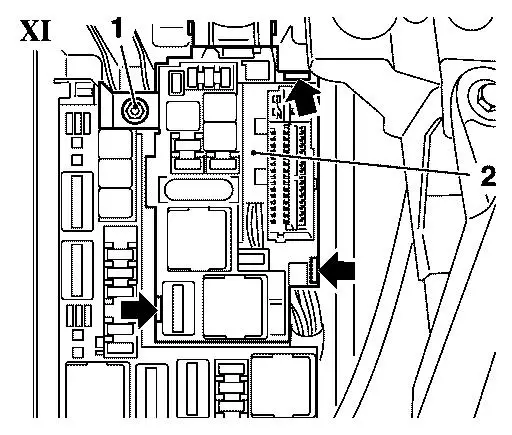

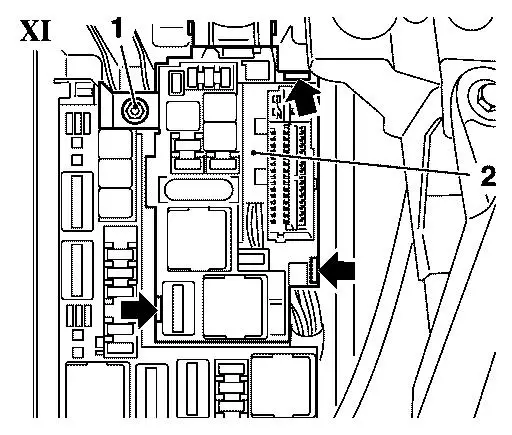

23. Install connector inset into engine compartment electronics

module (picture XI)

- Insert connector inset (2)

Note:

Latches (3x) have to clip in audible.

- Screw in 1x nut (1) and tighten 8 Nm

- Check all components in electronics module for proper mounting.

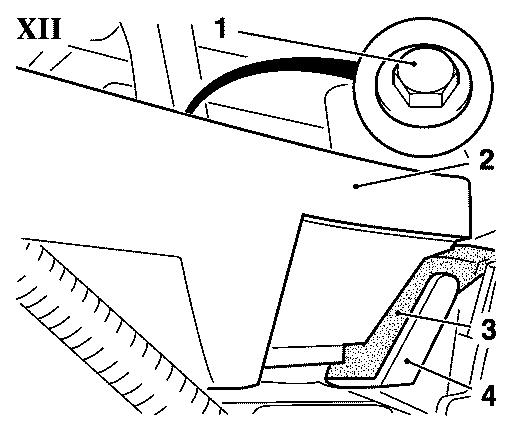

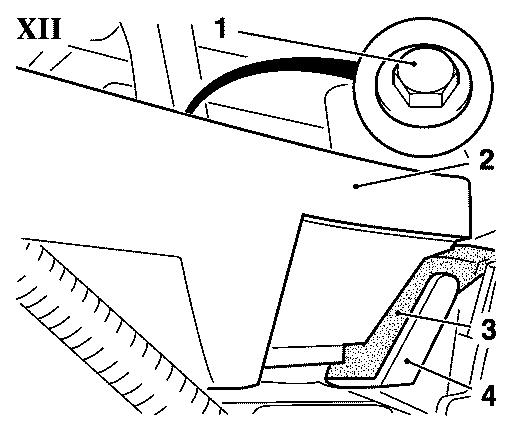

24. Seal bulkhead closing part below wind protection panel with

foam seals (picture XII)

- Unscrew screw (1) from bulkhead closing part (2)

- Lift bulkhead closing part and affix self-adhesive foam seal

strip (3) as shown

- Attach self-adhesive washer onto screw (1) and pull off adhesive

protective foil

Note:

Adhesive side has to show away from screw head.

- Screw in screw and tighten

Note:

Attend not to damage self-adhesive washer through tightening.

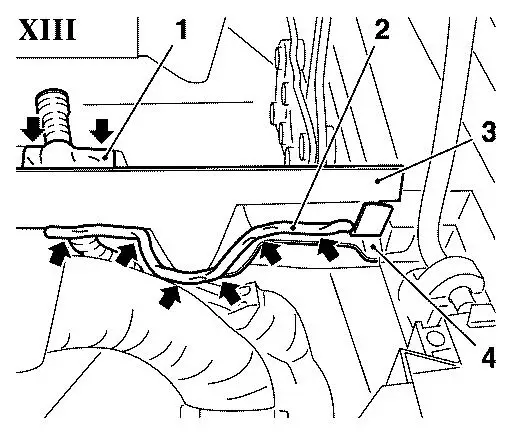

25. Seal bulkhead closing part below wind protection panel with

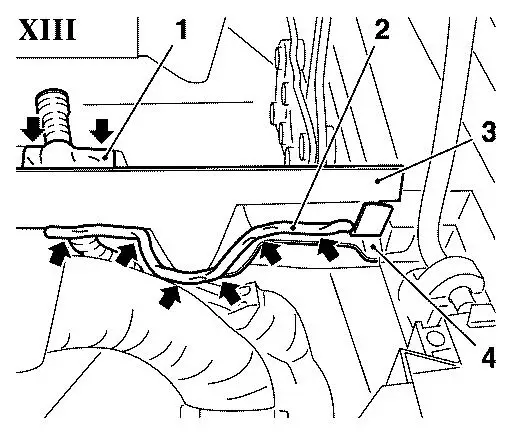

compound glueing seal (picture XIII)

- Apply compound glueing seal (P/N 90485251 - arrows) in the

area (1) of the opening for washer-fluid hose (arrows)

Note:

Seal opening on upper and lower side.

- Apply compound glueing seal (P/N 90485251 - arrows) in the

area (2) between bulkhead closing part (3) and body (4).

Note:

Before application of compound glueing seal fit wind protection

panel slackly and connect flanges of washer-fluid hose.

Washer-fluid hose must be positioned as shown behind the

wiring harness.

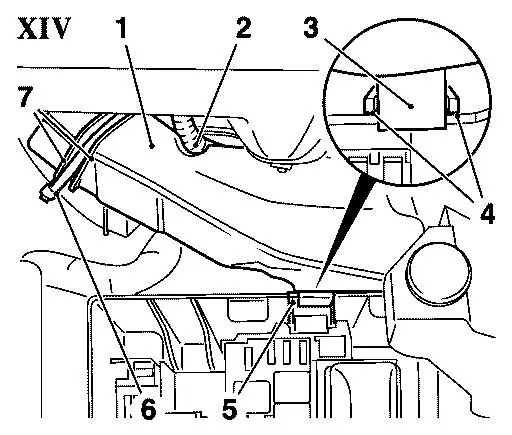

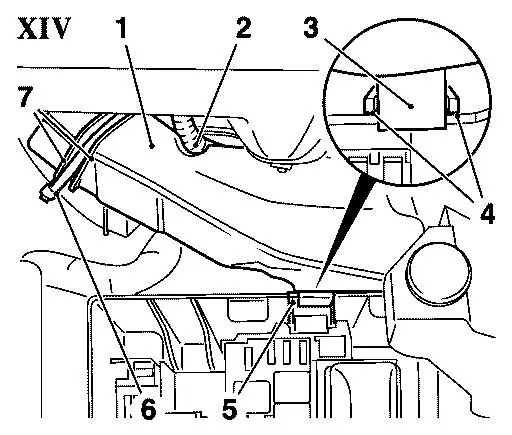

26. Install water protection cover (picture XIV)

- Install water protection cover (1) as shown

Note:

Washer-fluid hose (2) must run in designated guide.

- Attach fixing tab (3) on side panel (5) of electronics

module

Note:

Fixing tab (3) must be located between guides (4) of

electronics module.

- Affix cover to wiring harness with cable strap (6)

Note:

Cable strap must run between guides (7).

- Attach cover electronics module until latches clip in audibly.

27. Install wind protection panel

- see working procedure "Replace wind protection panelling",

group "A", Service-Instruction Corsa-D.

(Document number 01501230)

28. Connect battery.

29. Close bonnet.

30. Program volatile memory.

Spare-Parts: Part-No.: Catalogue-No.:

Repair kit 13301544 90 12 277

Shrinkable tubing 90543875 12 86 666

Connecting sleeve 90543865 12 86 663

Cable strap 90039907 12 88 900

Compound glueing seal 90485251 15 03 295

Washer self-adhesive 90184910 05 60 768

Special grease 09163339 19 48 877

Labour Times: TC: Hours:

U3 231 30 Sealing wiring harness 90 1,1

The costs for this repair will be covered during the normal warranty.

The regular warranty procedure will apply.

| FunctionalGroup: |

N - Electrical Equipment |

| Complaint Group: |

04 - Electrical failures |

| Trouble Code: |

P1120,P2121,B2580,other |

|