|

Standard Corrosion Protection Measures

General

In recent years, the subject of corrosion protection has been

forcefully pushed into the foreground as a result of increasingly

corrosive environmental pollution.

The customer expects that his vehicle is provided in series

production with high-grade corrosion protection with a long-term

protective action.

For these reasons, improvements are

continually being introduced into production:

- Increased use of sheet metal galvanised on both sides.

- Additional PVC sill protection for vehicles without panelling

in the area of the sill.

- Cavity protection wax in the entire underbody area.

- Cavity protection wax for all frame side members and

crossmembers.

In this section, the typical corrosion protection steps in

series production will be explained using a flowchart and

subsequent description of the individual steps.

The details of the individual steps may differ depending on

production plant.

The treatment of the engine compartment with protective wax is

no longer required.

Note: All of the

measures for corrosion protection discussed in the operations can

be understood with reference to the descriptions in this

section.

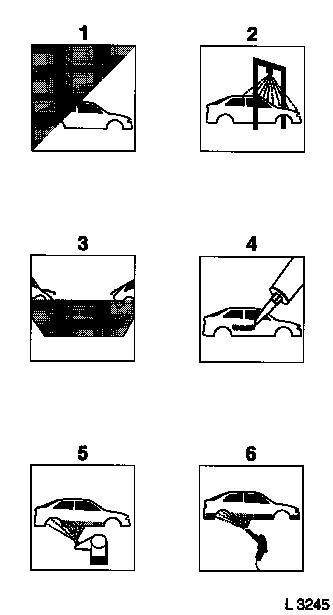

Flowchart for Corrosion Protection Steps

|

Step

|

Designation

|

|

1

|

Body shell

|

|

2

|

Spray dip phosphatisation

|

|

3

|

Cataphoretic dip priming

|

|

4

|

Seam seal

|

|

5

|

PVC underseal

|

|

6

|

PVC sill protection

|

|

|

|

Step

|

Designation

|

|

7

|

Primer

|

|

8

|

Top coat

|

|

9

|

Cavity protection wax

|

|

10

|

Underbody protection wax

|

|

11

|

Transit protective wax

|

|

|

|

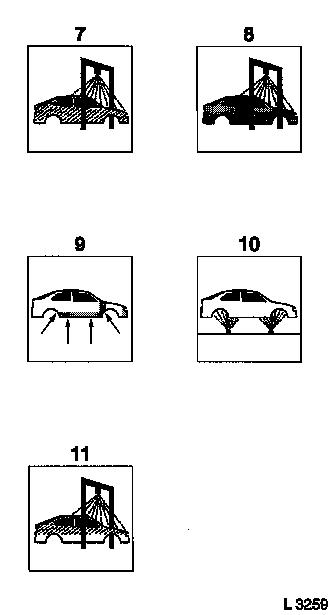

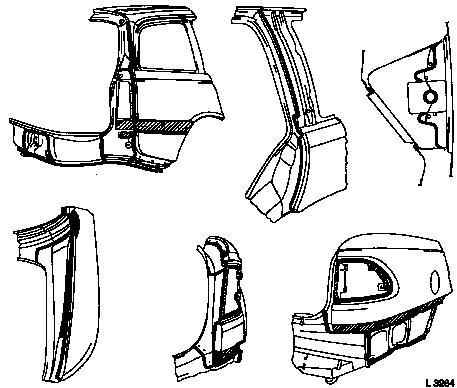

Body shell

Effective measures to prevent corrosion

start as early as the structural design of the body shell such as,

e.g.:

- Development of water-deflecting and dirt-deflecting body

shapes

- Deliberate selection of material at areas at risk of corrosion

due to galvanised metal sheets

- Optimum shaping and joining methods for body sheet-metal

parts

- Production of well-ventilated cavities

- Introduction of water drain holes

Example:

The good drainage of dirt and water is assisted by water drain

holes in door shells.

|

|

|

Spray / Dip Phosphatisation

Spray / dip phosphatisation with cleaning and rinsing operations

before and afterwards is the base of the paint structure.

The following sequence applies:

- Clean and degrease

- Spray / Dip Phosphatisation

- Rinse

- Blow with warm air

Spray / dip phosphatisation takes place by treating with a

phosphatising solution.

This causes a crystal layer to form which neutralises points of

different potential.

|

|

|

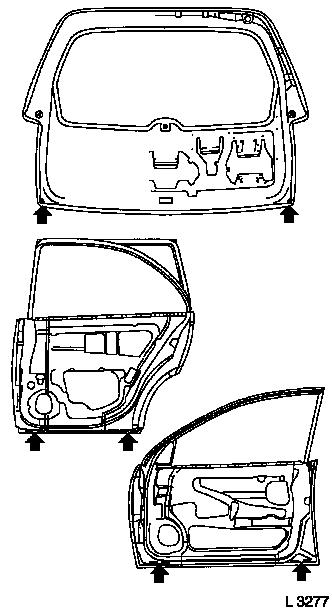

Cataphoretic Dip Priming (CDP)

CDP is the next corrosion protection step in series

production.

The following sequence applies:

- Cataphoretic dip priming

- Rinse

- Dry at approx. 180 °C / 25 minutes

The body (cathode) passes through a dip tank with water-soluble

paint (anode).

The positively charged paint particles displace to the body

under the effect of the electrical voltage and form a layer of

paint.

The thickness of the layer is determined by the amount of

electricity, the length of coating and the temperature of the paint

bath.

|

|

|

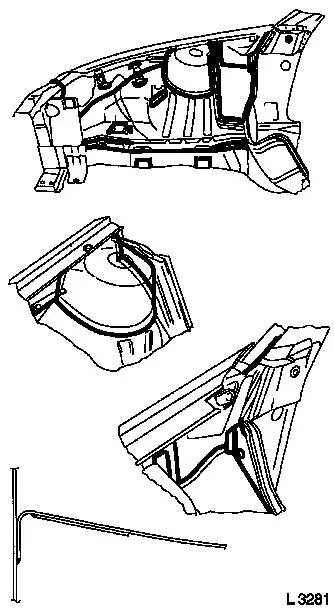

Seam seal

Heat-curing and solvent-free seam seals are applied to flanged

seams and folds and smoothed.

Included in this are flanges, welding

flanges and open seams in the following areas of the body

shell:

- Vehicle front section, wheel housing

- Vehicle front section, lower A-pillar

- Vehicle rear section, bottom pan

- Vehicle rear section, rear quarter panel

- Vehicle rear section, wheel housing

- Lower A-pillar, sill trim, bulkhead

|

|

|

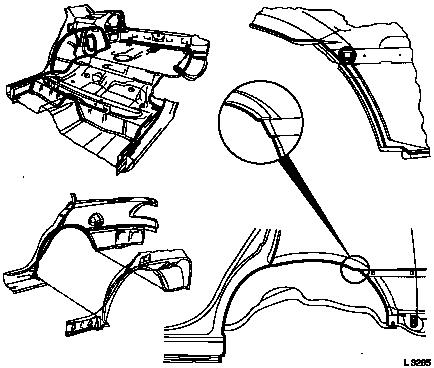

II Vehicle front section

Lower A-pillar

|

|

|

III Vehicle rear section

Bottom pan

|

|

|

IV Vehicle rear section

Rear quarter panel

|

|

|

V Vehicle rear section

Wheel well

|

|

|

VI Lower A-pillar

Sill trim, bulkhead

|

|

|

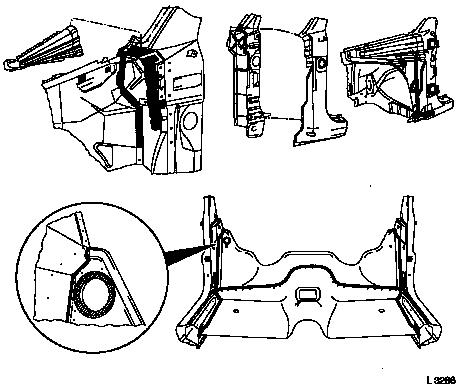

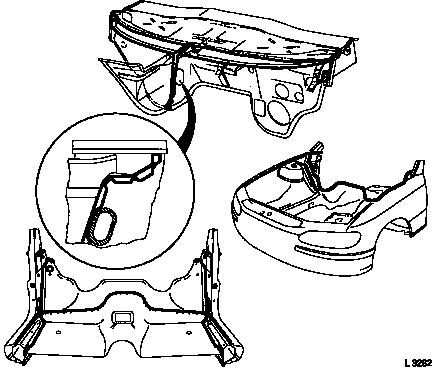

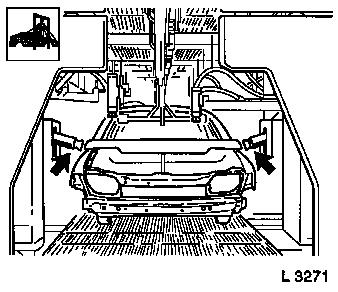

PVC underseal

PVC underseal is applied after CDP.

The areas of the vehicle underbody at risk of stone impacts are

coated in a targeted manner with PVC underseal.

This produces long-term protection against mechanical stress,

such as stone impact and corrosion.

To a greater extent, PVC underseal is applied fully

automatically using robots.

The remaining surfaces and flanges are sealed manually with PVC

or a combination material.

The final curing is achieved by drying the primer.

|

|

|

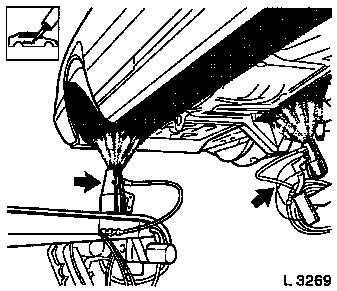

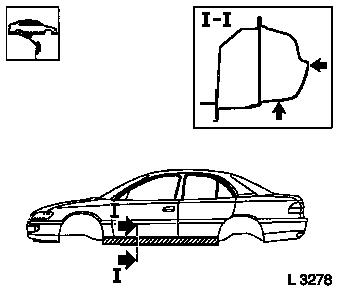

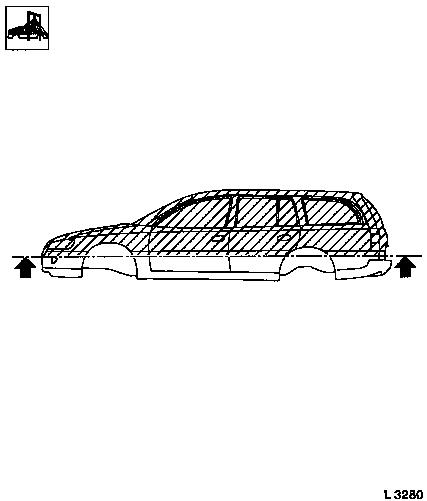

PVC sill protection

PVC sill protection cures on heating, is solvent-free and is

sprayed in a complex automatic spraying operation to give "visible

edges".

With regard to corrosion protection,

PVC sill protection has the following advantages:

- Adhesive

- Wear resistant

- Temperature resistant

- Water resistant

- Highly elastic

A straight, clean and seamless visible edge (section I –

I) is achieved in the spraying operation using a special

application procedure

|

|

|

Primer

The water-soluble primer is applied with an electrostatic rotary

atomiser unit.

The following sequence applies:

- Clean

- Coat with primer

- Dry at approx. 160 °C / approx. 35 minutes

Advantages of primer:

- Application with rotary atomiser, therefore application almost

without loss.

- High surface quality.

- Optimum Adhesion to CDP and PVC

- Optimum metal primer for top coat.

- Damping layer between CDP and top coat.

|

|

|

Top coat

The top coat forms the final layer of the paint structure due to

its blocking action towards the diffusion of water and oxygen.

The following sequence applies:

- Clean

- Apply top coat

- Dry at approx. 130 °C / approx. 30 minutes

Two different top coat systems may be used:

- 1-layer coat based on synthetic resin

- 2-layer coat with metallic or mica effect base coat and clear

coat

The top coats in the body outer area are sprayed on in

electrostatic rotary atomiser units.

The interior of the body is painted manually.

Plastic parts are provided with a special paint structure in

separate processes prior to assembly.

|

|

|

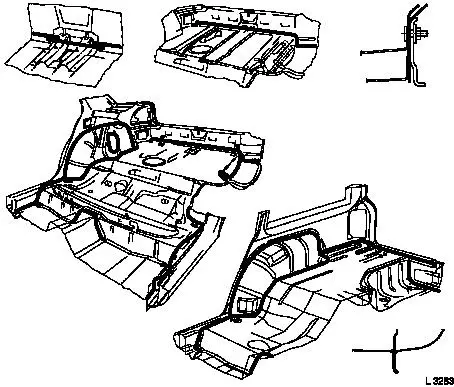

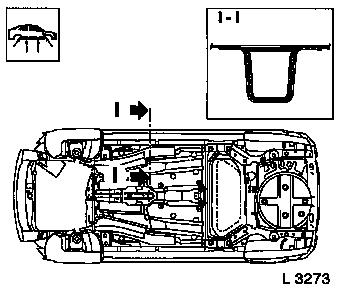

Cavity protection wax

After painting is finished, the following cavities are given a

protective wax protection:

- Sill panelling

- Bonnet.

- Front and rear door

- Wing.

- Luggage compartment lid and tailgate

- Wheel well

- Side member, crossmember

Advantages of cavity wax:

- High creep capability

- High non-volatile matter content

- Low solvent content

- Environmental compatibility

- Long-term protective action

- Once dried, forms a strong, sealed wax layer

|

|

|

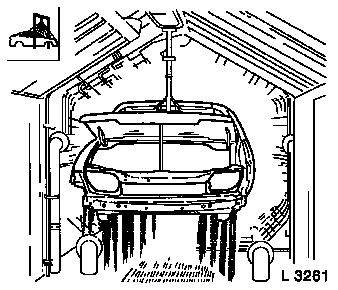

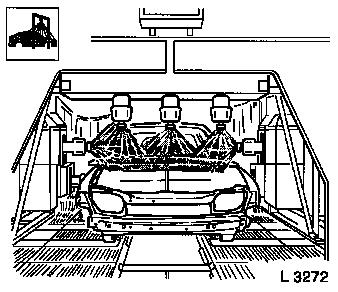

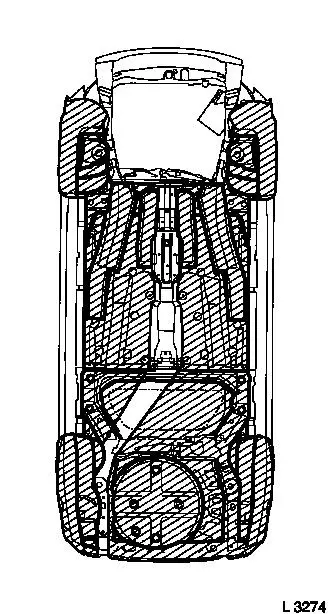

Underbody protection wax

In the further production sequence, all vehicles are given an

underbody protection wax to the vehicle underbody.

The entire vehicle underbody and its body attaching parts are

coated, such as, e.g.:

- Fuel tank

- Wheel wells with coil springs and shock absorbers

- Axle body

Catalytic converters and parts in the exhaust area are not

coated.

Advantages of underbody protection wax:

- High non-volatile matter content

- Low solvent content

- Environmental compatibility

- Optimum adhesion

- Once dried, forms a smooth clean wax layer

- Insulation and moisture barrier due to water-deflecting

property.

Underbody protection wax is applied in an automatic spraying

operation.

|

|

|

Bearing and Transit Protective Wax

The final application of bearing and transit protective wax

prevents corrosion damage caused by...

- Dust, dirt during transport

- Environmental pollution such as, e.g. soot

- Corrosive substances, such as bird droppings, insects or tree

resins

All vehicles are given bearing and transit protective wax in the

following areas:

- Roof

- Bonnet.

- Tailgate

- Wing.

- Doors

- Rear quarter panels

Paint-damaging particles only settle on the surfaces accessible

from above.

Therefore, enclosed, vertical surfaces (front, side, rear) are

not included in the wax coating.

|

|

|